DFG-SERIES SURFACE GRINDERS OPERATION AND PARTS MANUAL REV #3 (07/13/06) PAGE 32

ASSEMBLY INSTRUCTIONS/OPERATIONS

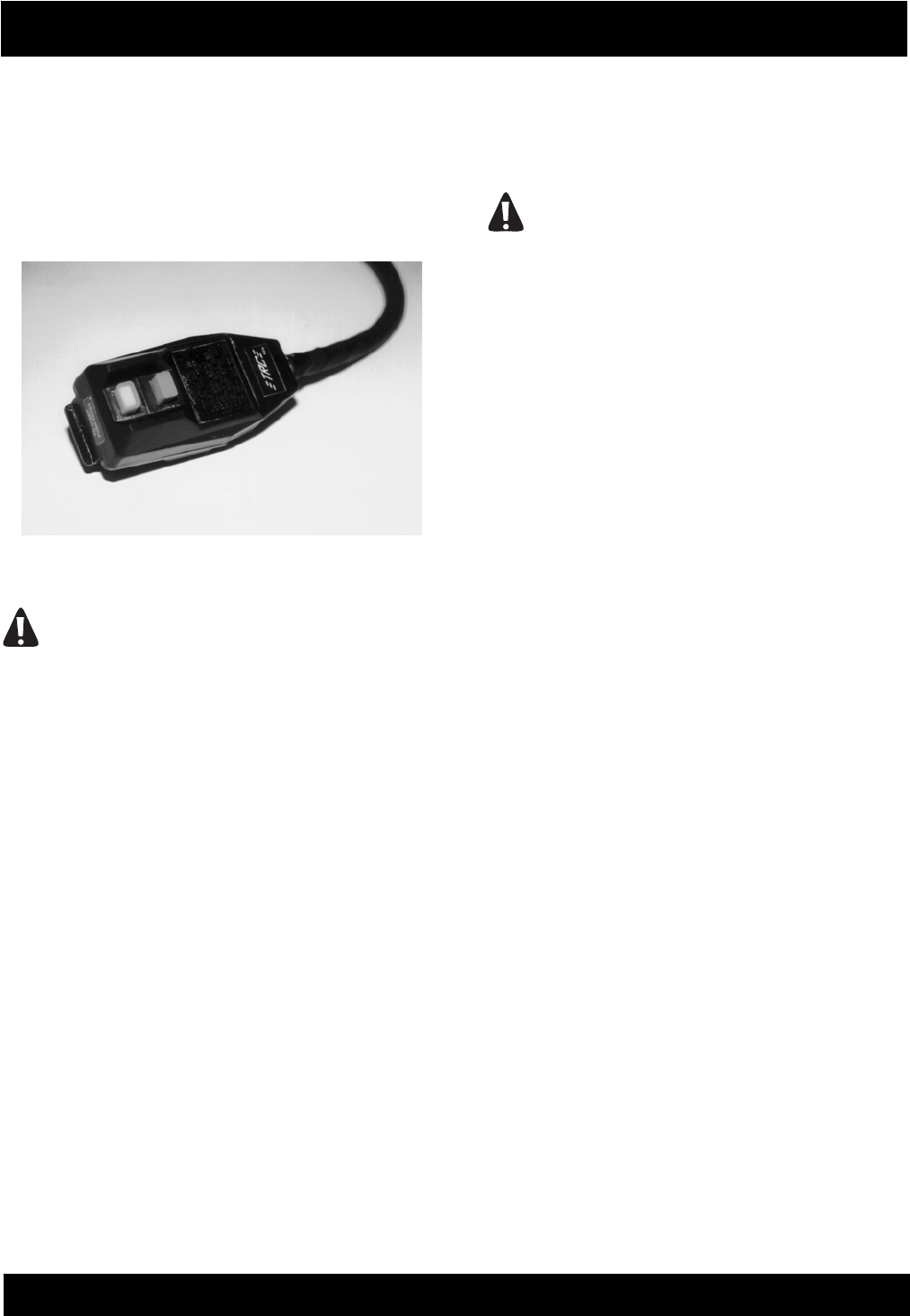

utilizing the SURFACE GRINDER. There is no

charge for this service. A qualified electrician

can also be consulted. If a 115 VAC power

outlet is selected, it is recommended that a

properly tested, externally mounted, ground fault

circuit interrupter (GFCI) be utilized at all times

as an additional safety precaution. Ground fault

circuit interrupters are not available for operation

on 230 VAC. FIGURE 34.

FIGURE 34

DANGER

FOR MAXIMUM PROTECTION AGAINST A

FAULT, ALWAYS CONFIGURE THE GROUND

FAULT CIRCUIT INTERRUPTER TO BE

PLUGGED INTO THE EXTENSION CORD. A

CONFIGURATION WITH THE GROUND FAULT

CIRCUIT INTERRUPTER PLACED BETWEEN THE

POWER SOURCE AND THE EXTENSION CORD

WILL NOT AFFORD MAXIMUM PROTECTION

AGAINST A POTENTIAL FAULT.

6) Couple the NEMA 6-20R receptacle and the

NEMA 6-20P plug together.

7) Grasp the operator handle with firm gripping.

When starting the electric motor, apply a down

force directly to the operator handle to help

reduce the amount of machine weight against

the work surface. Turn the ON/OFF switch to the

ON position. Reduce the amount of applied

down force on the operator handle as the

electric motor attains its operational speed.

When operating on 115 VAC, the electric motor

will require additional starting time to help

compensate for the additional starting amperage

requirement. This time is usually within two

seconds of activating the ON/OFF switch.

8) The DFG/E Series electrically powered

SURFACE GRINDER is not equipped with a

centrifugal clutch assembly. The electric motor is

directly coupled to the multi-accessory discs by

a V-belt/spur gear transmission.

DANGER

AS SOON AS THE ELECTRIC MOTOR HAS

STARTED, THE OPERATOR MUST BE IN A

POSITION TO ASSUME DIRECT AND FULL

CONTROL OF THE SURFACE GRINDER.

FAILURE TO ASSUME DIRECT AND FULL

CONTROL CAN RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

9) The DFG/E Series electrically powered

SURFACE GRINDER is stopped by moving the

ON/OFF switch located on the operator handle

to the OFF position. For safety considerations, it

is also recommended that the extension cord be

disconnected from both the SURFACE

GRINDER and electric power source whenever

the SURFACE GRINDER is not in use on the

job site.

STARTING THE DFG/G SERIES GASOLINE

POWERED SURFACE GRINDER ON THE

JOBSITE.

1) Position the SURFACE GRINDER on a flat and

level surface of firm foundation.

2) Refer to the material supplied by the engine

manufacturer for the correct starting, operation

and stopping procedures.

3) The DFG/G Series SURFACE GRINDER is

equipped with a centrifugal clutch assembly. The

clutch is designed to engage at approximately

2400 RPM engine speed. Normal operation of

the clutch will allow the engine to operate at its

designated idle speed without the multi-

accessory discs rotating. If the multi- accessory

discs rotate below the designated engine idle

speed, do not continue to operate the

SURFACE GRINDER until the problem has

been properly corrected. Consult the Customer

Service Department for specific information.

There is no charge for this service.