Turbomachinery Package Specification Taurus 60 Compressor Set and Mechanical Drive

6 Gearbox

6.1 General Description

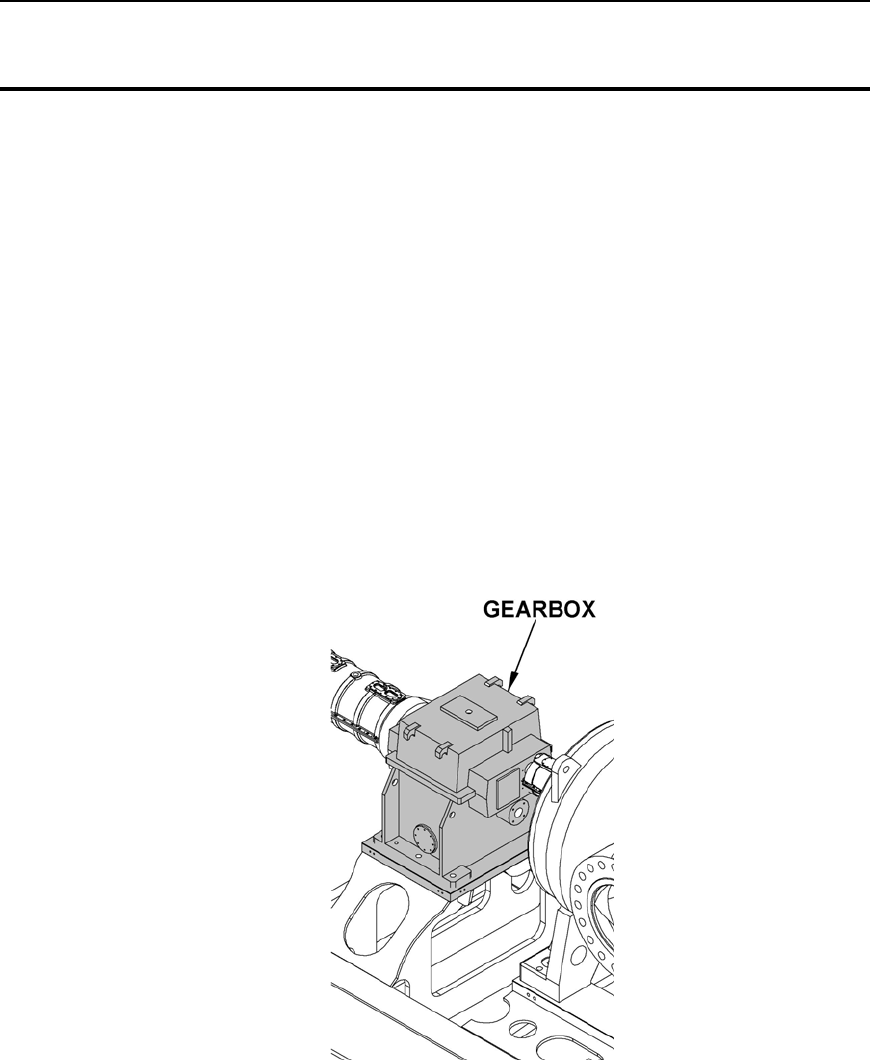

If required, a gearbox (Figure 8) can be provided selected specifically for compressor set

and mechanical drive applications. The gearbox uses few moving parts, providing high

reliability and ease of assembly and disassembly. The gearbox is designed for

continuous-duty operation and matches the output speed of the turbine or tandem

compressor to the required operating speed of the driven compressor. Gear lubrication is

provided by the package lube oil system. The gears can be serviced without removing

the main case.

Depending on the application, the gearbox may be primary speed increasing or speed

decreasing (between the gas turbine and the first or only driven compressor) or it may be

inter-body speed increasing (between tandem compressors).

The gear unit is designed in accordance with American National Standards

Institute/American Gear Manufacturers' Association (ANSI/AGMA) standards as

described in Solar's specification ES 2238. The gear unit design includes a fabricated

steel or cast iron housing, double helical precision hobbed and finished ground gear

elements, and split steel-backed babbitt lined journal bearings on all shafts.

Figure 8. Typical Gearbox

6.1.1 Primary Speed-Increasing Gearbox

The primary speed-increasing gearbox will have a specific gear ratio and speed range.

The gearbox increases the output speed of the turbine to the required operating speed of

the driven compressor, optimizing the power turbine speed for each application. The

gearbox output shaft direction of rotation is counterclockwise, when viewed from the aft

(exhaust) end of the package looking forward.

© 2009 Solar Turbines Incorporated. All rights reserved. TPS60CSMD/309

20