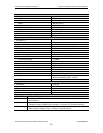

Turbomachinery Package Specification Taurus 60 Compressor Set and Mechanical Drive

CONTROLLOGIX

CONTROLLER

VIBRATION

MONITOR

I/O

MODULES

BACKUP

SHUTDOWN

SYSTEM

FIRE & GAS

SYSTEM

TURBINE

CONTROL

PANEL

TT4000

TT4000S

OPERATOR

PANEL

CONTROLNET

CONNECTIONS TO PACKAGE AND FIELD INSTRUMENTATION

VARIABLE

FREQUENCY

DRIVES

SERIAL LINK TO

SUPERVISORY

CONTROL

MOTOR CONTROL

CENTER

SAFE AREA OPERATOR

INTERFACE

ONSKID OPERATOR

INTERFACE

PRIMARY CONTROL SYSTEM COMPONENTS

Figure 16. Turbotronic System Architecture

10.3 Component Descriptions

10.3.1 Controller

The ControlLogix controller, running RSLogix 5000 software, provides primary control.

Project-specific programs are created in a Windows-based system and uploaded to the

controller. The RSLogix 5000 software supports ladder and function block programming

and complies with the International Electrical Code (IEC) 61131-3 standard for

programmable controllers.

10.3.2 ControlNet 1.5

Operating at 5 Mbps, the network is repeatable and deterministic. Cabling is redundant

with two separate channels carrying the same information. The maximum total length of

the network is 1000 meters without the use of repeaters. However, this length decreases

based on the number of nodes on the network. A practical design limit is 800 meters.

10.3.3 Input/Output Modules

Flex I/O modules provide an interface between the package instrumentation and the

processor. Specific modules handle discrete inputs, analog inputs, temperature inputs,

speed inputs, discrete outputs and analog outputs.

10.3.4 Vibration Monitoring System

The system uses 1701 FieldMonitors and associated sensing devices from Bently

Nevada. The capacity of each monitor is eight vibration channels plus a keyphasor input.

© 2009 Solar Turbines Incorporated. All rights reserved. TPS60CSMD/309

36