Turbomachinery Package Specification Taurus 60 Compressor Set and Mechanical Drive

8 Fuel System

8.1 General Description

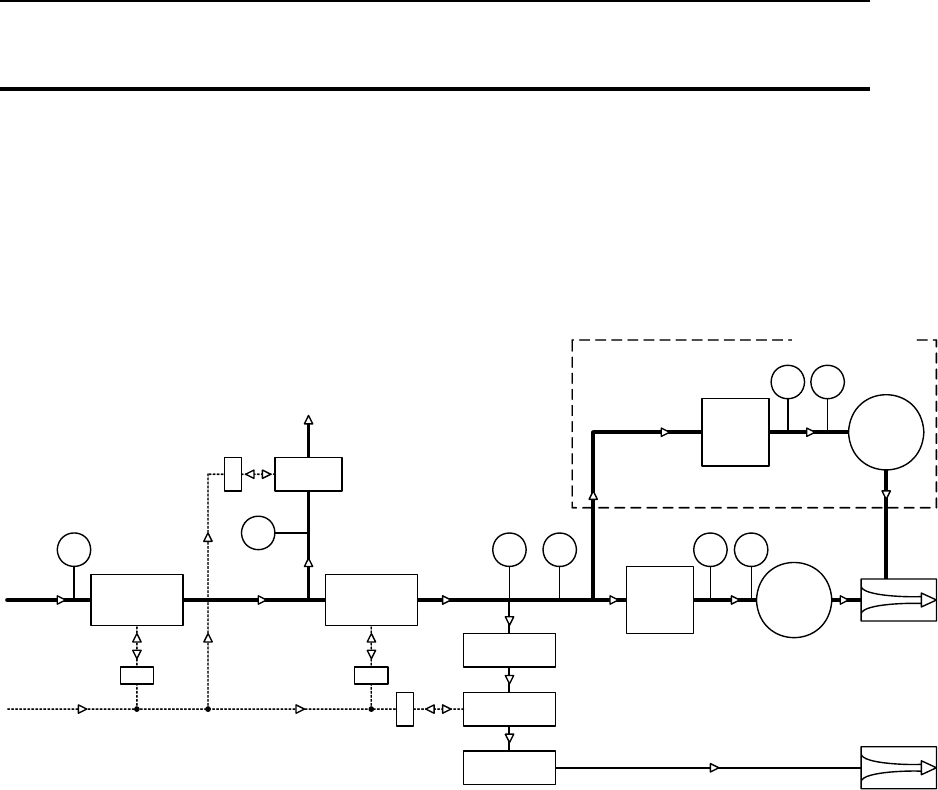

The fuel system (Figure 12), in conjunction with the control system, includes all

necessary components to control ignition and fuel flow during all modes of operation.

There are two available configurations:

• Gas fuel – conventional combustion

• Gas fuel – SoLoNOx combustion

MAIN

FUEL

CONTROL

VALVE

TPRT

PRIMARY

SHUT OFF

VALVE

TORCH

REGULATOR

TORCH SHUT

OFF VALVE

VENT

VALVE

V

S

VS VS

TP

TP

MAIN FUEL

MANIFOLD

GAS FUEL

INJECTOR

TORCH

V

S

TORCH

REGULATOR

SECONDARY

SHUT OFF

VALVE

PILOT

FUEL

CONTROL

VALVE

PILOT FUEL

MANIFOLD

GAS VENT

AIR

FUEL

LEGEND

TP = PRESSURE TRANSMITTER

TPD = DIFFERENTIAL PRESSURE TRANSMITTER

RT = RTD (TEMPERATURE)

VS = VALVE SOLENOID

ONLY FOR SOLONOX

TP TP

TP TP

Figure 12. Typical Fuel System Schematic

8.1.1 Conventional Combustion System

Solar’s conventional combustion system uses fuel injectors equally spaced around the

combustor to inject fuel into the combustion chamber. The fuel injected into the

combustion chamber is controlled during starting and steady-state operation to maintain

stable combustion.

8.1.2 SoLoNOx Combustion System

The SoLoNOx combustion system uses special fuel injectors with main and pilot fuel

ports. The fuel injected through these ports is controlled during starting and steady-state

operation to maintain stable combustion and minimize the formation of nitrous oxides

(NOx), carbon monoxide (CO), and unburned hydrocarbon (UHC) emissions. To further

regulate emission levels, combustion airflow is regulated using a bleed valve mounted on

the combustor case. The SoLoNOx combustion system also includes an additional inlet

gas filter/coalescer for mounting offskid.

8.1.3 Fuel System

For conventional combustion, the fuel system includes:

• Supply pressure transmitter

• Pilot air operated primary gas fuel shutoff valve

© 2009 Solar Turbines Incorporated. All rights reserved. TPS60CSMD/309

26