14

MAINTENANCE

MAINTENANCE

To ensure efficient operation and longer life of the air

compressor, prepare and follow a routine maintenance

schedule.The routine described in this section is intended for

an air compressor used under normal daily working

conditions. If necessary, modify the schedule to suit the

conditions under which you use your compressor.

Modifications will depend upon hours of operation and

working environment. Operating air compressors in

extremely dirty or hostile environments will require more

frequent maintenance checks.

NOTE: See FEATURES AND CONTROLS and OPERATION

for control locations.

Follow the hourly or calendar intervals, whichever occurs

first:

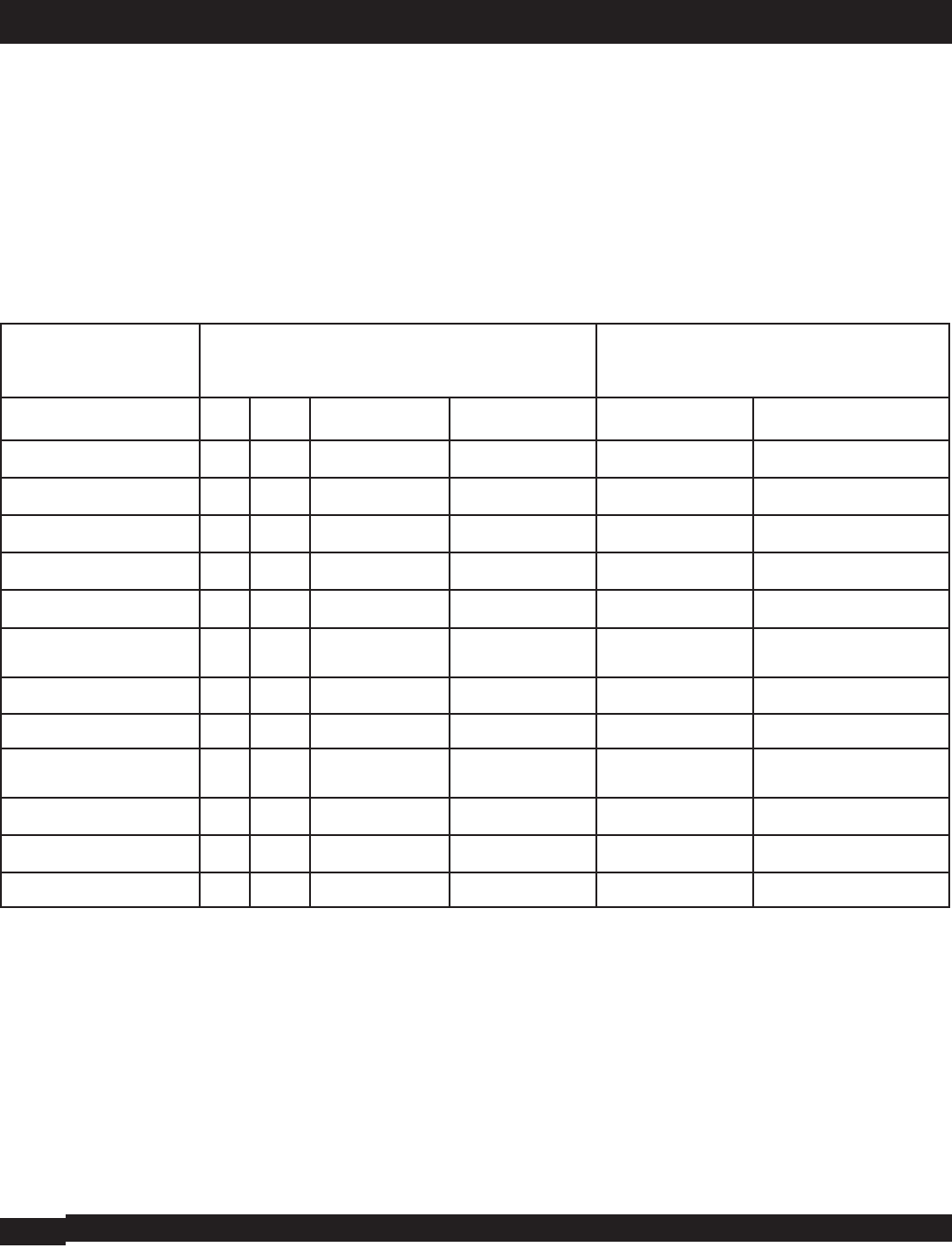

Maintenance

Schedule

Service Intervals

Service Dates

Fill in as you complete

regular service

Maintenance Task Daily Weekly

Every 50 Hours

or Yearly

Every 100 Hours

or Yearly

Clean Unit X

Inspect Safety Valve X

Inspect Fittings/Valves X

Inspect Engine Oil Level X

Inspect Pump Oil Level X

Inspect Engine Air

Cleaner

X

1

Change Engine Oil

X

2

Clean Spark Arrester X

Inspect and Clean Pump

Air Filter

X

Change Pump Oil

X

3

Inspect Spark Plug X

Inspect Safety Labels

X

4

1

Change more often under dirty or dusty conditions

2

Change oil after first 5 hours of operation, then every 50 hours thereafter

3

Change oil after first 100 hours of operation, then every 300 hours thereafter

4

Inspect annually, replace as necessary