General Recommendations

Regular maintenance will improve the performance and

extend the life of the air compressor.

The air compressor’s warranty does not cover items that

have been subjected to operator abuse or negligence.To

receive full value from the warranty, the operator must

maintain the air compressor as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your air compressor. See any authorized

Briggs & Stratton Power Products dealer for service.

All service and adjustments should be made at least once

annually. Follow the requirements listed in MAINTENANCE

SCHEDULE on page 14.

NOTE: Once a year you should clean or replace the spark

plug and replace both the engine and pump air filters.A new

spark plug and clean air filter assure proper fuel-air mixture

and help your engine run better and last longer.

Emissions Control

Maintenance, replacement or repair of emissions control

devices and systems may be performed by any non-road

engine repair establishment or individual. See EMISSIONS

CONTROL SYSTEM, on page 26.

Maintenance

Maintenance consists of keeping the air compressor clean.

Store the unit in a clean, dry environment where it will not

be exposed to excessive dust, dirt, moisture or corrosive

vapors. Cooling air fins on the air compressor’s engine must

not become clogged with dirt, leaves or any other foreign

material.

NOTE: DO NOT use a garden hose jet or flammable liquids

to clean air compressor’s engine.Water can enter engine fuel

system and cause problems.

Cleaning Unit

To prolong compressor life, perform these steps weekly. If the

operating environment is particularly dirty, clean unit daily.

1. With spark plug disconnected, use a soft cloth and a

small brush for cleaning accumulated dirt and debris

from the following locations:

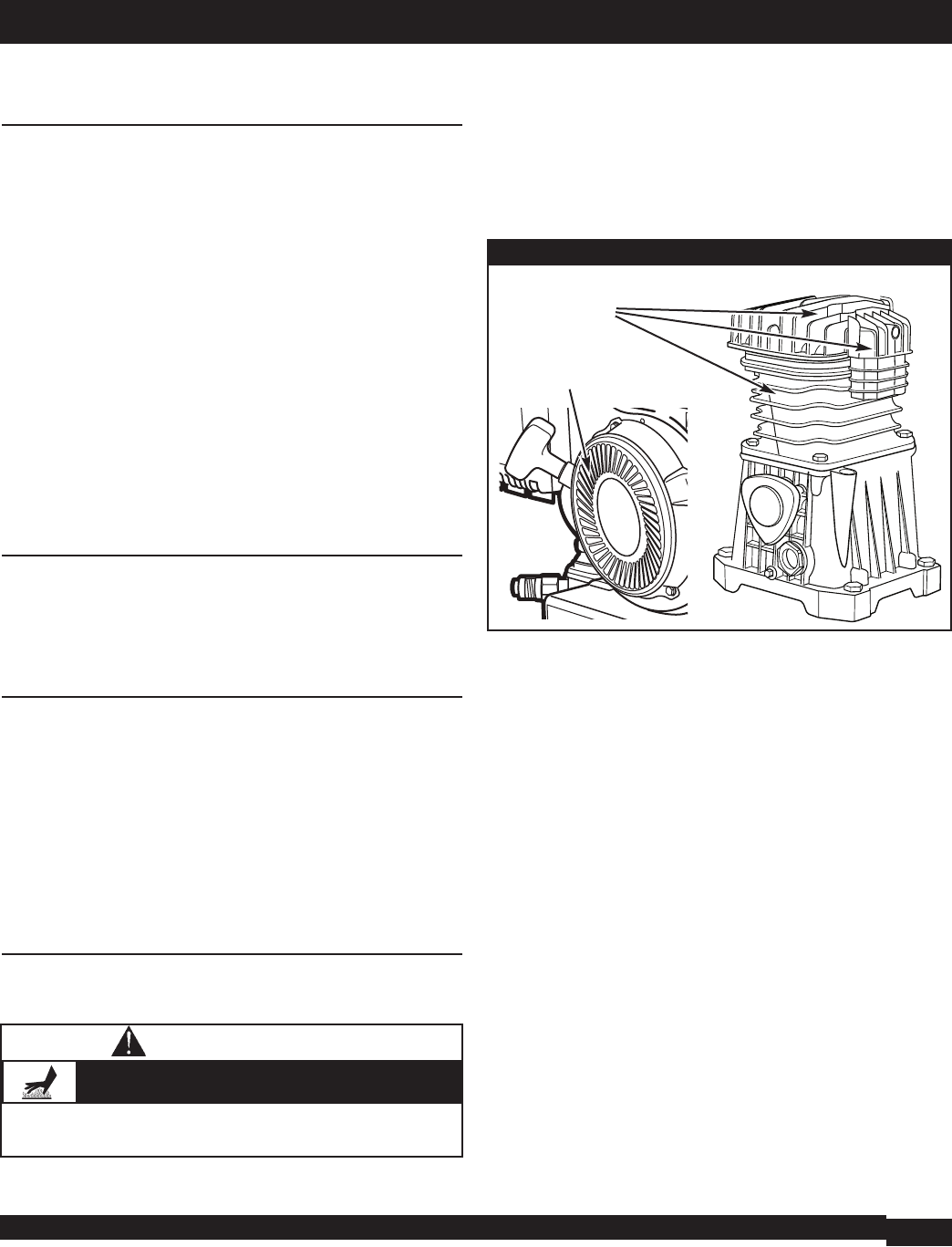

• Cooling fins on top and sides of Air Compressor

Pump, and engine blower housing slots

(see Figure 13).

• Oil fill locations and adjacent areas on both Air

Compressor Pump housing and Engine

• Oil drain plugs and adjacent areas on both Air

Compressor Pump housing and Engine

• Pressure Control knob, gauges, quick connect fitting,

Drain Valves and Safety Valve

• Engine ON/OFF Switch and adjacent area

• Choke Lever, Engine Speed Lever, Fuel Valve Lever

and adjacent area on carburetor

• Spark plug and adjacent area

• Pilot Valve and toggle

• Fuel Tank Cap and adjacent area

MAINTENANCE

15

Figure 13 - Cooling Fins

• DO NOT touch hot parts and AVOID hot exhaust gases.

• Allow compressor to cool before servicing.

Hot parts and exhaust gases can exceed 150

°

F and

can cause burns.

WARNING

Engine Blower Housing Slots

Cooling Fins