CC1800XL Concrete Saw Manual 23

7. Place a set collar, washer, new wheel, and another

washer (in this order) onto the end of the axle. Slide

the axle back into the axle hole on the right, and

then push the assembly parts to the right. Note: The

axle should not protrude from either side of the

frame base

8. Raise the saw and retighten the rear axle setscrews

to secure the rear axle; lower the saw again.

.

9. Push the group of items from step 5 tightly up

against the left side of the saw, and tighten the set

collar setscrew to secure the wheel assembly.

10. Push the group of items from step 7 tightly up

against the right side of the saw, and tighten the set

collar setscrew to secure the wheel assembly.

Battery (Gas Model)

WARNING

• Ignitable explosive gases are emitted from the

battery. DO NOT expose the battery to sparks

or open flames.

• Disconnect the battery prior to servicing all

saw components (unless stated otherwise).

• Always keep the battery cable clamps

away from the battery terminals when

the battery is disconnected to avoid

accidental connections while servicing.

CAUTION

• Use a proper battery tester when testing the

battery strength.

• Use protective eyewear or a face shield, and

avoid contact with the skin when

handling/servicing the battery.

Battery Type

12 Volt, Group U1

Servicing the Battery

1. Turn off the master disconnect.

2. Remove the battery support brace nuts and the

support brace.

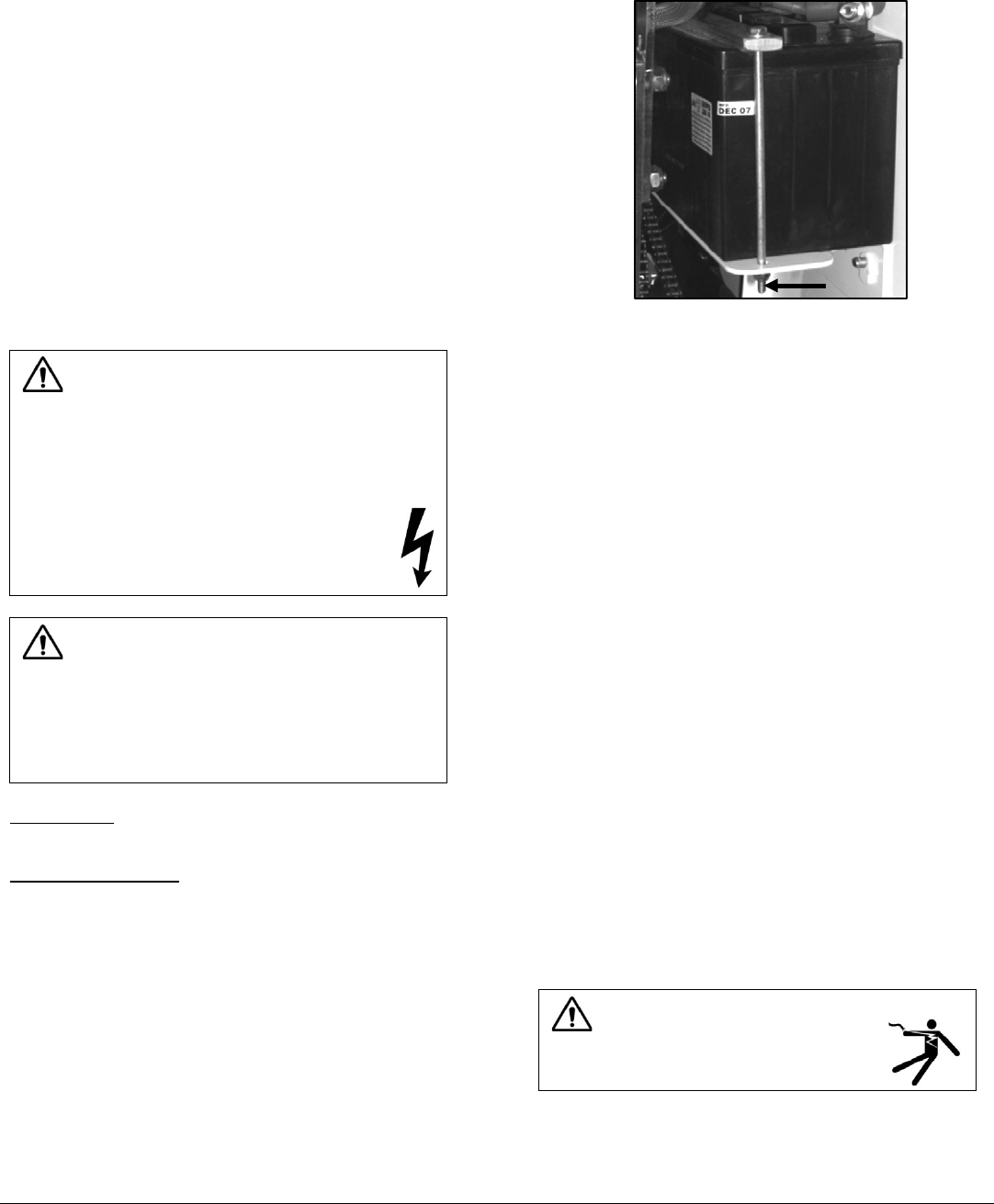

Figure 28: Battery Support Brace

3. Remove the negative battery boot and disconnect

the negative battery cable lead from the negative

battery terminal.

4. Remove the positive battery boot and disconnect the

positive battery cable lead from the positive battery

terminal.

5. Slide the battery off the battery platform, keeping it

level.

6. When replacing the battery, place a new battery

onto the battery platform, keeping it level. Bring the

old battery to a recycling facility; many battery

retailers also accept old batteries.

7. When cleaning the battery, inspect its terminals,

clamps, and cables for damages and corrosion.

Clean the terminals and clamps using a wire brush,

or use another approved technique for cleaning. Use

acid-free, acid-resistant grease to grease the battery

clamps and terminals.

8. Reconnect the positive battery cable lead to the

positive battery terminal and replace the battery

boot.

9. Reconnect the negative battery cable lead to the

negative battery terminal and replace the battery

boot.

10. Fit the battery support brace over the battery and

retighten the nuts to secure the brace.

11. Turn on the master disconnect (as necessary).

Electrical System

WARNING

• Always use the correct size fuses

(amps) to prevent fires.

Check the in-line fuse (applicable models) below the

control panel if the engine does not start when actuating

the ignition key, and replace the fuse as necessary.