BOOK 0958-B

25

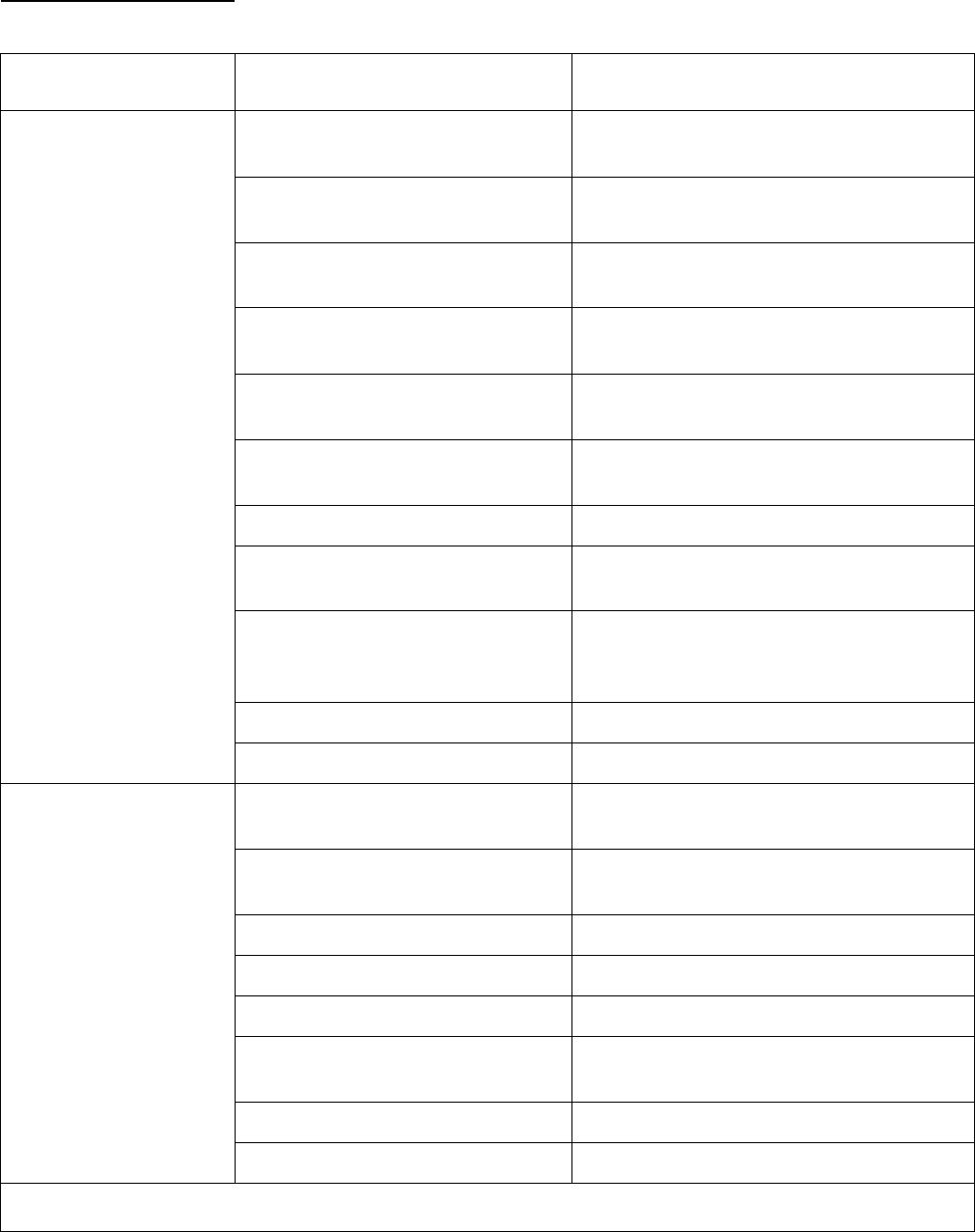

TROUBLESHOOTING

TABLE 6. TROUBLESHOOTING

INDICATION POSSIBLE CAUSE CORRECTIVE ACTION

AC line open

Be sure rated AC line voltage is applied to the

controller.

Operator controls inoperative or con-

nected incorrectly

Repair accordingly.

Open circuit between Connectors E1

and E2

A wire jumper or switch must connect E1 to

E2.

Controller not reset

Initiate a Stop command and then a Start com-

mand.

Line Voltage Selection Jumper J1 in

wrong position

See Step 5 on page 5 under, “Installing The

Controller.”

Controller not enabled

Be sure +24 VDC is applied to Terminal TB2

8.

Loss of speed reference signal Check for 0 - 10 VDC speed reference signal.

Controller not adjusted correctly

Turn the ACCEL and CUR LMT potentiome

ters fully counterclockwise (100%).

Open shunt field winding or wiring to

the motor shunt field, causing loss of

torque

a

Check the motor shunt field and associated

circuitry for a loose connection or a broken

wire. Repair accordingly.

Motor failure Repair or replace the motor.

1. Motor won’t start

(See “Inoperative

Motor,” page 21)

Control board failure Replace the control board.

Wiring faulty or incorrect

Check all external wiring terminating in the

controller. Correct accordingly.

Circuit, component, or wiring

grounded

Remove ground fault.

SCR1, SCR2, SCR3 or SCR4 shorted Replace shorted SCR’s or the control board.

Bridge Diode D1b shorted Replace shorted diode or the control board.

Varistor RV1 shorted Replace RV1 or the control board.

Shunt Field Diode D39, D40, D41, or

D42 shorted

a

Replace shorted diode or the control board.

Motor shunt field shorted or grounded

a

Repair or replace the motor.

2. Controller line fuse

blows when AC line

power is applied to the

controller

Control board failure Replace the control board.

Cont’d on next page