BOOK 0958-B

26

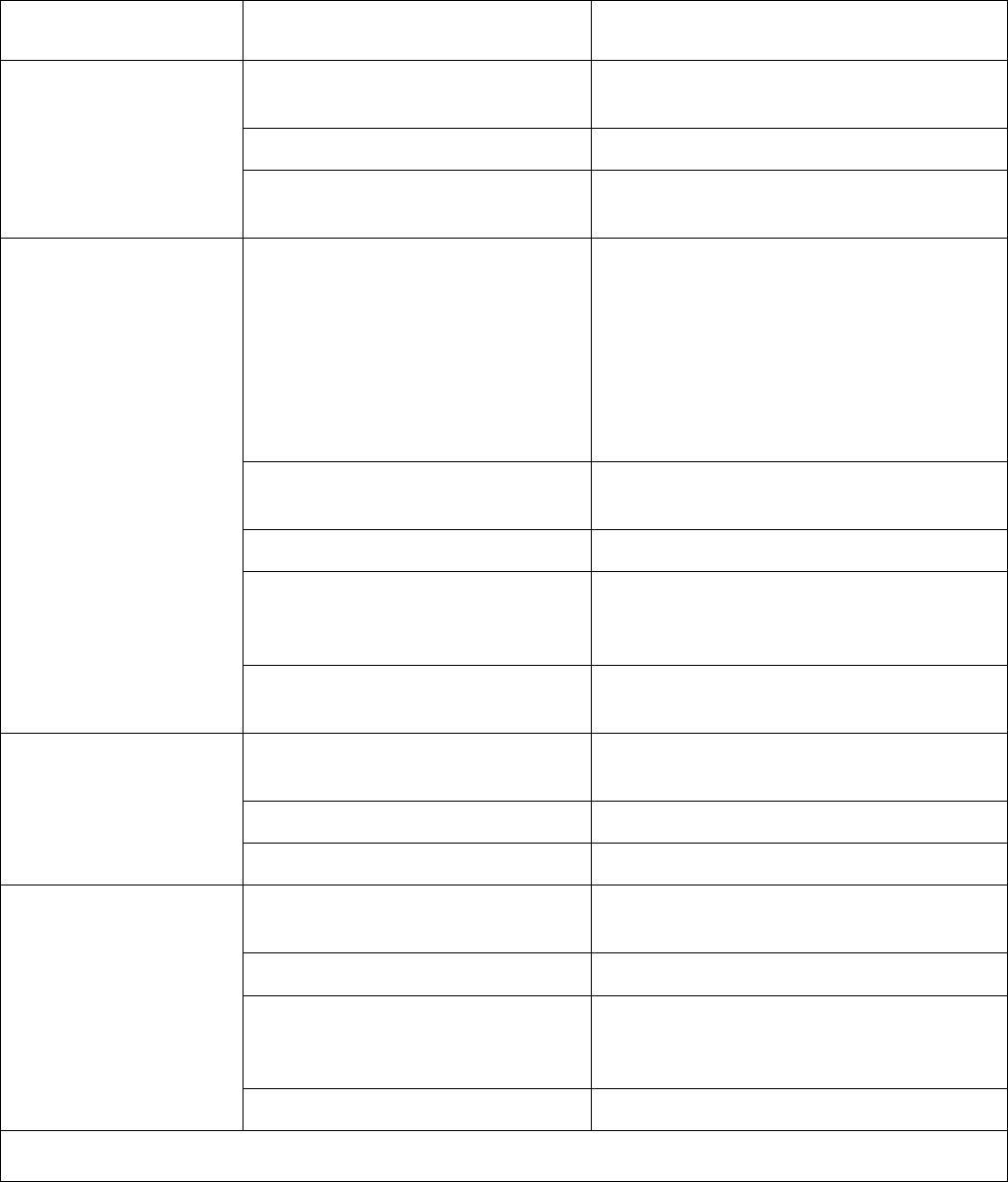

TABLE 6. TROUBLESHOOTING

INDICATION POSSIBLE CAUSE CORRECTIVE ACTION

One or more SCR‘s or Diode D1b

shorted

Replace shorted devices or the control board.

Motor shorted or grounded Repair or replace the motor.

3. Controller line fuse

blows when a Start com-

mand is initiated

Control board failure causing SCR’s to

turn-on fully

Replace the control board.

Motor overloaded

Check shunt field current.

a

Low shunt field

current causes excessive armature current. If

field current is adequate, check for a mechani

cal overload. If the unloaded motor shaft does

not rotate freely, check motor bearings. Also

check for a shorted motor armature. Motor

overload can also be caused by incorrect gear

ratio. Correct accordingly.

Loose or corroded connection. Wiring

faulty, incorrect, or grounded

Check all terminals, connections, and wiring

between the line, controller, and motor.

Motor shorted or grounded Repair or replace the motor.

One or more SCR‘s or Diode D1b

breaking down (shorting intermit-

tently)

Replace faulty devices or the control board.

4. Controller line fuse

blows while the motor is

running

Control board failure causing SCR

false firing or misfiring

Replace the control board.

Minimum speed not adjusted correctly

Turn the MIN SPD potentiometer counter

clockwise.

Motor armature grounded Correct ground fault.

5. Minimum speed

excessive

Control board failure Replace the control board.

Maximum speed set too high

Turn the MAX SPD potentiometer counter

clockwise.

Controller not calibrated correctly Refer to Steps 4 and 5 on page 5.

Open shunt field winding or wiring to

the motor shunt field

a

Check the motor shunt field and associated

circuitry for a loose connection or a broken

wire. Repair accordingly.

6. Maximum speed

excessive

Motor field demagnetized

b

Replace the motor.

Cont’d on next page