BOOK 0958-B

27

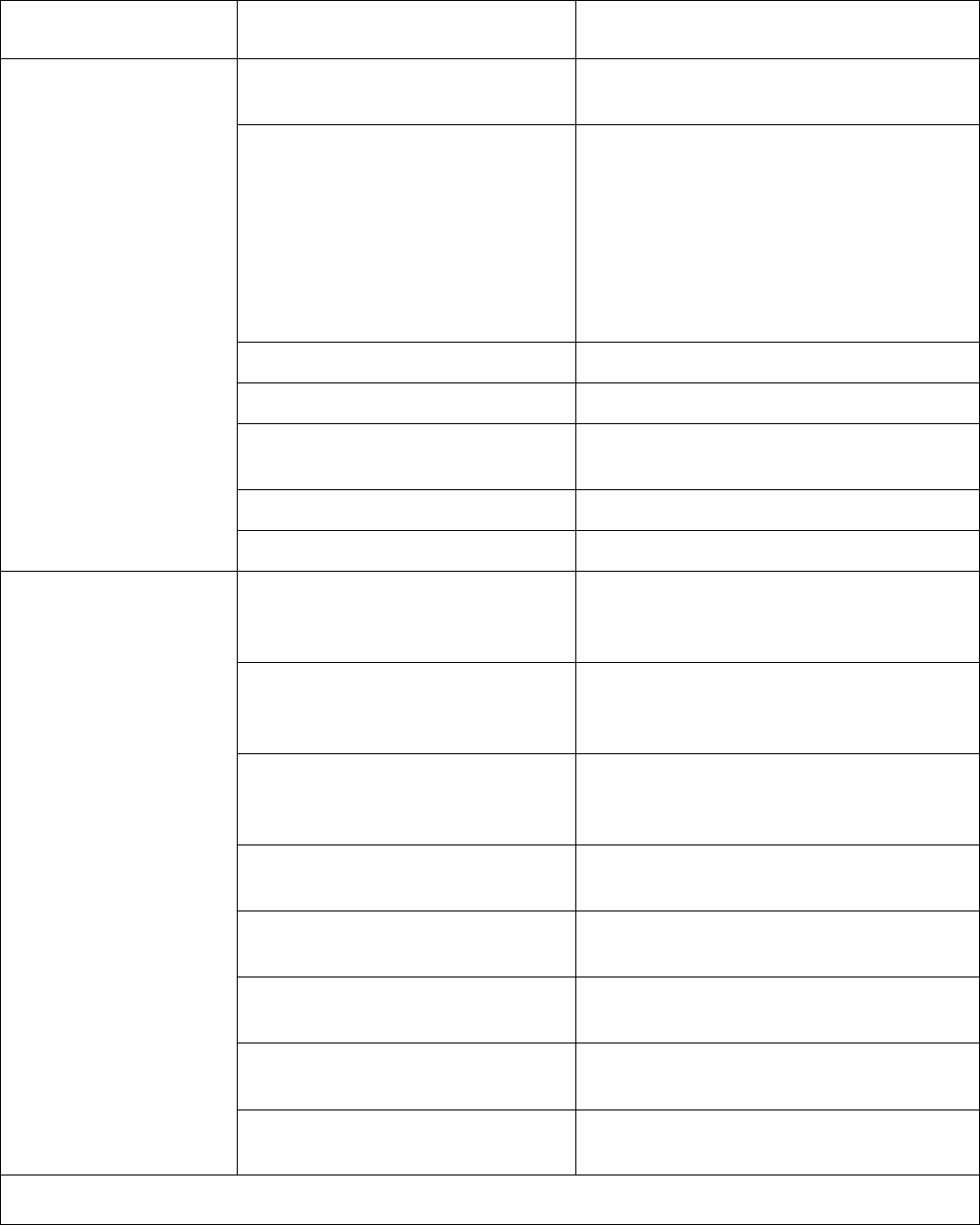

TABLE 6. TROUBLESHOOTING

INDICATION POSSIBLE CAUSE CORRECTIVE ACTION

Low line voltage

Check for rated line voltage, ±10%, on the

controller line terminals.

Motor overloaded

Check shunt field current.

a

Low shunt field

current causes excessive armature current. If

field current is adequate, check for a mechani

cal overload. If the unloaded motor shaft does

not rotate freely, check motor bearings. Also

check for a shorted motor armature. Motor

overload can also be caused by incorrect gear

ratio. Correct accordingly.

Maximum speed set too low Turn the MAX SPD potentiometer clockwise.

Current limit set too low Turn the CUR LMT potentiometer clockwise.

Current scaling jumper J4 in wrong

position

See Step 4 and Table 2 on page 5.

Motor field demagnetized

b

Replace the motor.

7. Motor won’t reach top

speed

Control board failure Replace the control board.

AC line voltage fluctuating

Observe line voltage with a voltmeter or oscil

loscope. If fluctuations occur, correct condi

tion accordingly.

Loose or corroded connection. Wiring

faulty, incorrect, or grounded

Check all terminals, connections, and wiring

between the line, operator controls, controller,

and motor.

Oscillating load connected to the

motor

Stabilize the load. Turning the IR/TACH

potentiometer counterclockwise may mini

mize oscillations.

Voltage Selection Jumpers J1, J2 or J3

in wrong position

See Step 5 on page 5 under, “Installing The

Controller.”

IR compensation not adjusted cor-

rectly

See the IR Compensation adjustment instruc

tions on page 23.

Maximum speed not adjusted correctly

See the Maximum Speed adjustment instruc

tions on page 23.

Motor faulty

Check motor brushes. Replace if needed.

Repair or replace the motor.

8. Unstable speed

Tachometer generator or coupling

faulty (if used)

Repair accordingly.

Cont’d on next page