DIGITAL INPUTS / FOUNDATION

™

FIELDBUS (OPTIONS)

13 - 1

ETC00781(4) Series 100 e 02/2004

13. Digital Inputs / Foundation

™

Fieldbus (BINOS

®

100 2M/F option only)

Be sure to observe the safety measures for all workings at the analyzer!

13.1 Digital Inputs

13.1.1 General

To remotely control different conditions of analyzer BINOS

®

100 2M/F, the analyzer can

optionally be equipped with 7 digital inputs . They are available at terminals on the rear side

of the analyzer (Fig. 1-8, Item 9). The inputs are active only if the analyzer is equipped with built-

in solenoid valve block or if the solenoid valves are connected to the digital outputs (see

chapter 29.5.1). Observe the wiring hints in chapter 29.10 !

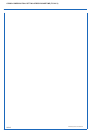

Fig. 13-1: Terminal assignments “Digital Inputs”

The analyzer may be controlled by either control voltages or floating contacts.

A “low signal” has to be < 1.4 V dc, a“high signal” has to be > 3.5 V dc (max. 30 V dc). Reference

point is terminal “V-” (

⊥⊥

⊥⊥

⊥).

To work with floating contacts, customer can use the intrinsic-safe output voltage of “+ 5 V DC”

at terminal “V+”.

13.1.2 Start of Calibration

Inputs “E1 to E3”: The analyzer will start a calibration procedure if control signal changes from

“low-level” to “high-level”. These inputs have a higher priority than inputs “E4 to E7”

DIGITAL INPUTS

E3

E2

E1

E4

E5

E7

E6

V-

V+

+ 5 V DC

⊥⊥

⊥⊥

⊥

start zero calibration channel 1 & 2

start span calibration channel 1

start span calibration channel 2

open zero gas valve

open span gas valve 1

open span gas valve 2

close sample gas valve / sample gas pump off