Flush

313289S 17

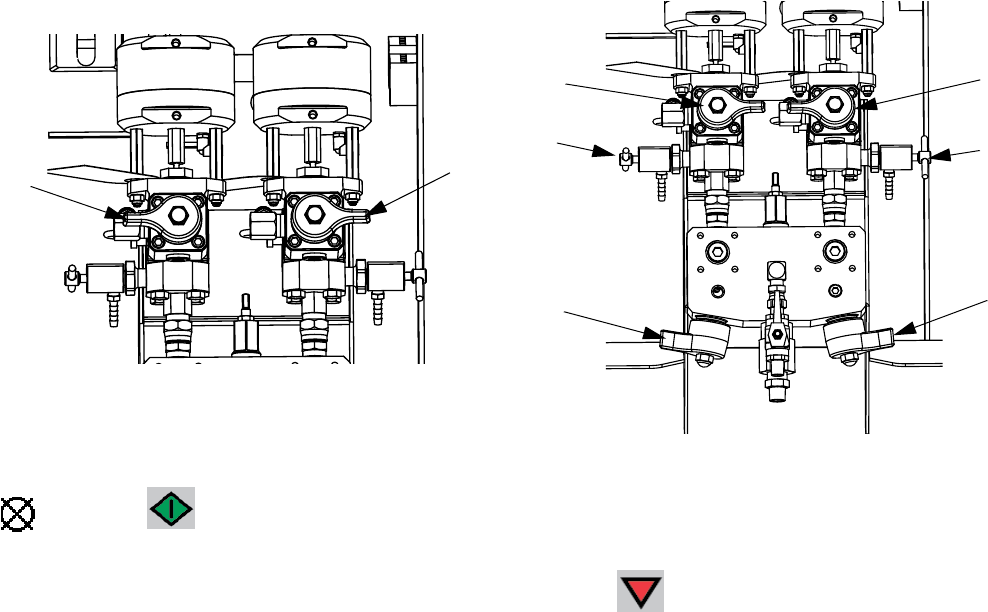

5. Open recirculation valves (AC, AD) for respective

pump dispense side. Run pumps until the A and B

reservoirs are empty. Salvage the material in sepa-

rate, clean containers.

NOTE:

When priming or flushing the pumps, it is normal to get

cavitation or pump runaway alarms. Clear the alarms

, and press again as necessary. These

alarms prevent excessive pump speeds that can dam-

age pump packings.

6. Wipe the reservoirs clean, then add solvent to each.

Move circulation lines to waste containers.

7. Repeat Step 4 to flush through each side until clean

solvent exits recirculation hose.

8. Stop and move recirculation hoses back to reser-

voirs. Continue recirculating until machine is thor-

oughly flushed.

9. Close recirculation valves (AC, AD) and open mix

manifold valves (AH, AJ). Dispense fresh solvent

through mix manifold valves and out gun.

10. Close mix manifold valves (AH, AJ).

11. Slowly open sampling valves (AE, AF) to flush sol-

vent through until clean. Close sampling valves.

Press .

12. Follow Pressure Relief Procedure, page 12.

13. Remove pump fluid filters, if installed, and soak in

solvent. Clean and replace filter cap. Clean filter

o-rings and leave out to dry. Do not leave o-rings in

solvent.

14. Close main air valve (E).

NOTE:

Always leave some type of fluid, such as solvent or oil,

in the system to prevent scale build up. This build up

can flake off later. Do not use water.

AC

AD

r_312359_313289_6

AD

AF

AJ

AC

AE

AH

r_312359_313289_7