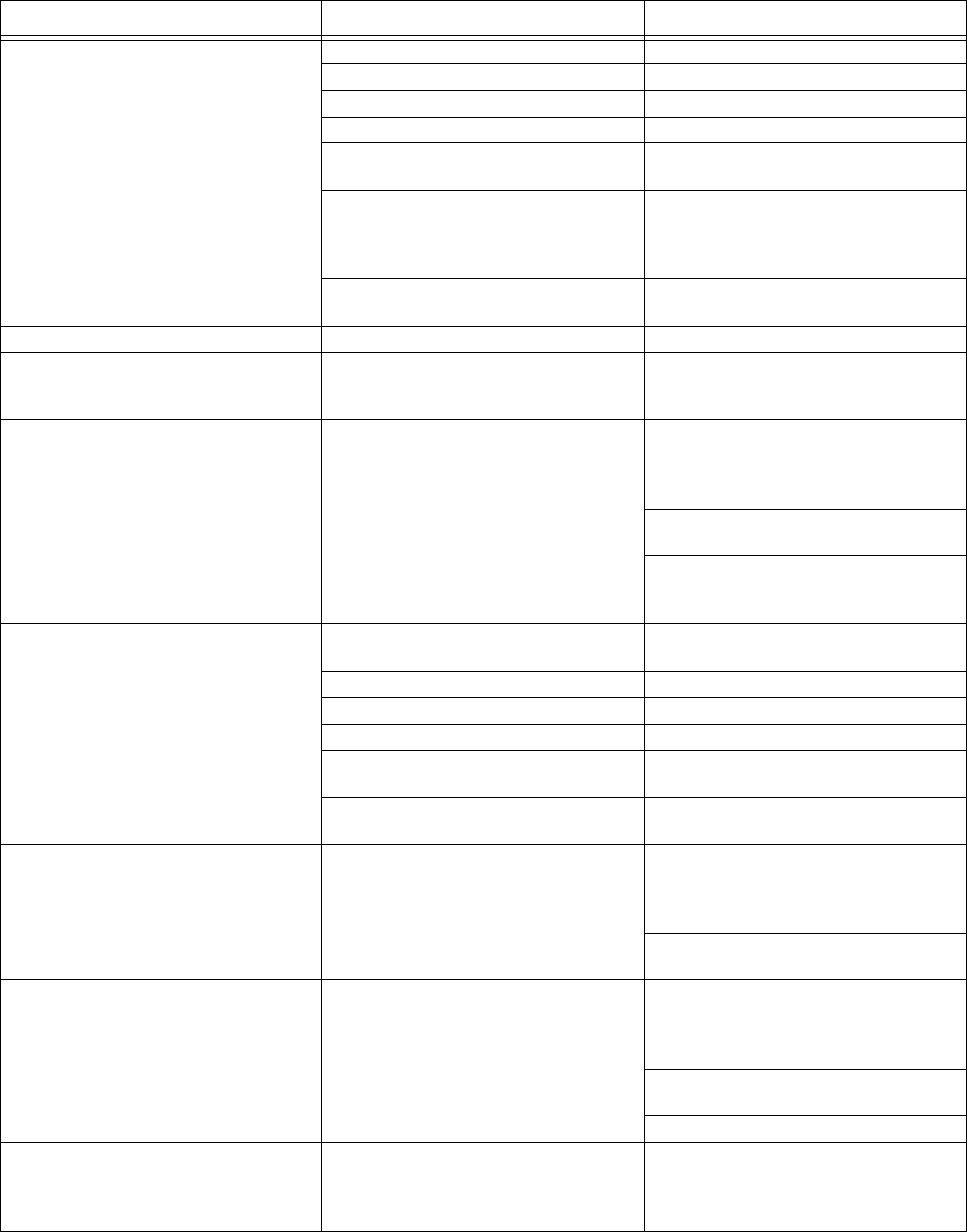

Troubleshooting

22 313289S

System runs erratically. Air filter(s) clogged. Replace elements. Clean. Replace element(s). See page 31.

Air supply hoses undersized. Replace hoses with appropriate size.

Air compressor undersized. Use larger air compressor.

Air supply pressure tank undersized. Use larger pressure tank.

Inlet air pressure gauge drops below 50

psi (0.35 MPa, 3.5 bar) while spraying.

See solutions above for system runs

erratically problem.

A and/or B air motor has ice. Open air motor de-ice bleed air control.

Allow ice to melt. Dry the compressed air.

Heat the compressed air. Use a smaller

tip and lower flow rate.

Pump is binding. Repair lower. See Remove Displace-

ment Pump, page 44.

Air supply relief valve opens. Air regulator set too high. Lower setting.

Turbine alternator makes high-pitched

whining noise, or quits.

Turbine bearings worn. (Setting turbine

air regulator too high, wears bearings.)

Replace turbine cartridge. See Alterna-

tor Power Supply Control Compo-

nents, page 38.

Display module cycles on and off. Turbine is not supplying enough power to

board.

Increase turbine regulator setting to

18 +/- 1 psi (12.6 +/- 10 kPa, 1.26 +/- 0.07

bar). Check voltages on information

screen. 10-14 Vdc when spraying.

Check turbine and electrical control

exhaust air for restrictions.

Replace turbine cartridge. See Alterna-

tor Power Supply Control Compo-

nents, page 38.

Flow rate too low. Air supply hose is too small or too long. Use 3/4 in. (minimum) ID hose. See

Technical Data, page 85.

Inadequate air supply. Use larger CFM compressor.

Air pressure to pumps too low. Increase pressure.

Fluid A or B filters plugged. Clean filters. See pump manual.

Spray tip too small. Relieve pressure. Install larger tip. Follow

gun manual instructions.

Mixer or hoses partially plugged or too

restrictive.

Inspect parts for cured material. Clean or

replace, or use larger hoses and mixer.

Receive ratio alarm after starting in spray

mode while using remote mix manifold.

A and B hoses do not fill to correct pres-

sure ratio simultaneously. Therefore,

spray time increases in order to balance

pressure. Ratio screen bar graph stays to

one side until pressure balances.

While in circulation mode, close circula-

tion valves and increase pressure in

hoses until correct spray pressure is

achieved.

Select correct hose size to balance your

volume ratio. See manual 312749.

Receive ratio alarm while using remote

mix manifold after a significant change in

pressure.

A and B hoses do not fill to correct pres-

sure ratio simultaneously. Therefore,

spray time increases in order to balance

pressure. Ratio screen bar graph stays to

one side until pressure balances.

While in circulation mode, close circula-

tion valves and increase pressure in

hoses until correct spray pressure is

achieved.

Select correct hose size to balance your

volume ratio. See manual 312749.

Change pressure slowly while spraying.

Erratic pressure at spray gun when using

feed pumps.

Feed pressure is too high. Feed pressure

at metering pump is too high on up

stroke. Doubles the feed pressure to out-

let pressure on up stroke only.

Use lowest feed pressure needed to

maintain feed.

Problem Cause Solution