Model G0602/G0752 (Mfg. Since 11/12)

-21-

The chip pan and the base of the lathe have

holes that allow the machine to be mounted to

a workbench. You MUST mount your machine

to a workbench to prevent it from unexpectedly

moving during operation, which could lead to

personal injury or property damage.

Follow these guidelines when mounting your

lathe to ensure safe and accurate cutting

results:

• Make sure that the workbench can adequate-

ly support the weight of the machine and

materials and that it will not move or vibrate

during operation.

• Use a silicon sealant between the lathe and

the chip pan to prevent coolant or other fluids

from leaking through onto the bench or floor.

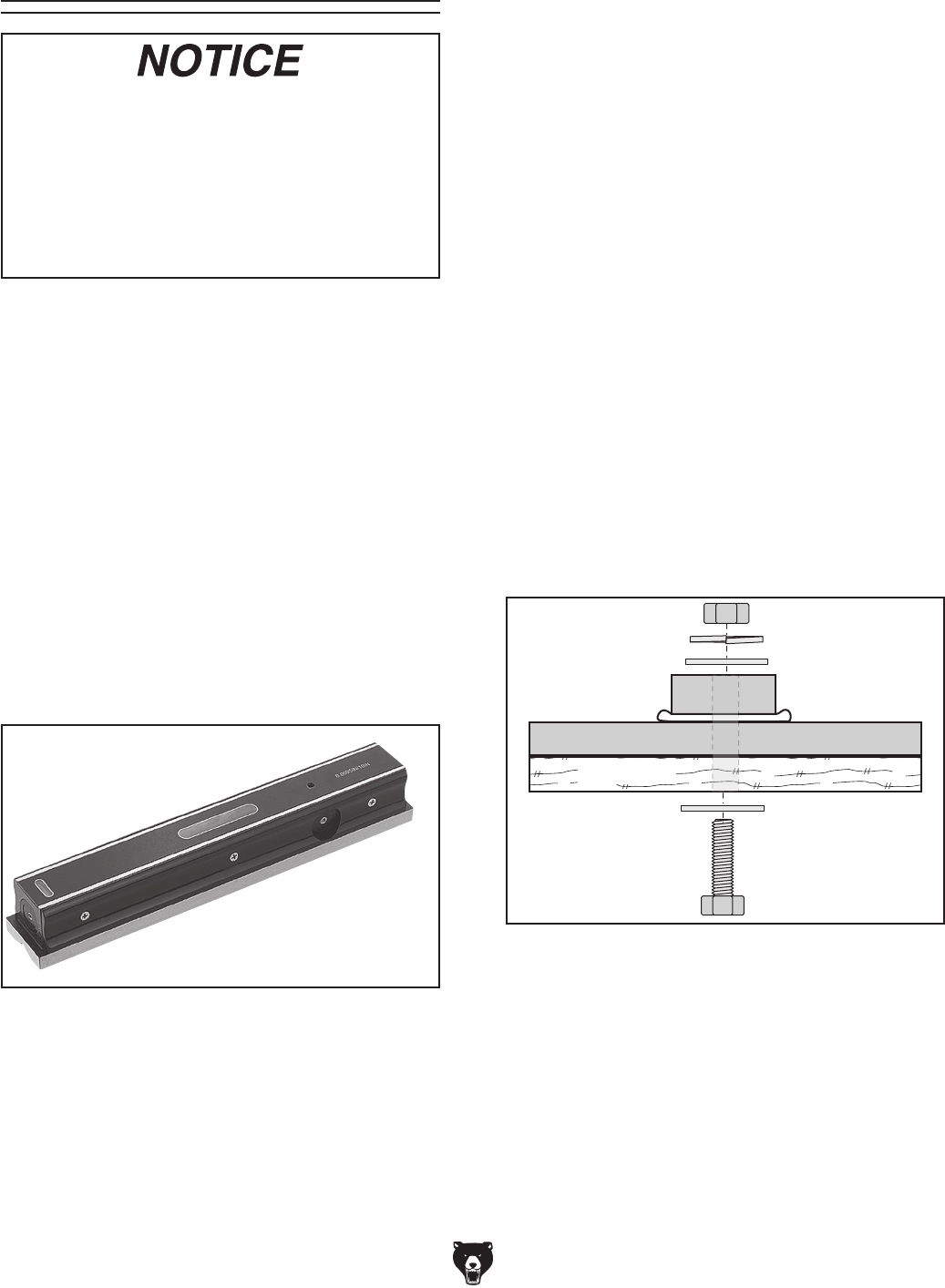

To mount the lathe and chip pan to the workbench,

drill holes all the way through the workbench, and

use hex bolts, washers, and hex nuts to secure

the lathe to the workbench, as illustrated in

Figure 16.

Leveling & Mounting

Figure 15. Grizzly Model H2683 12" Master

Machinist's Level.

Leveling machinery helps precision components,

such as bedways, remain straight and flat during

the lifespan of the machine. Components on a

machine that is not level may slowly twist due to

the dynamic loads placed on the machine during

operation.

For best results, use a precision level that is at

least 12" long and sensitive enough to show a

distinct movement when a 0.003" shim (approxi-

mately the thickness of one sheet of standard

newspaper) is placed under one end of the level.

See the figure below for an example of a high

precision level.

Leveling

Mounting

Chip Pan

Workbench

Hex Bolt

Flat Washer

Flat Washer

Silicon

Lock Washer

Hex Nut

Lathe

Figure 16. Example of a through mount setup.

For accurate turning results and to prevent

warping the cast iron bed and ways, the lathe

bedways MUST be leveled from side-to-side

and from front-to-back on both ends.

Re-check the bedways 24 hours after

installation, two weeks after that, and then

annually to make sure they remain level.