Model G0602/G0752 (Mfg. Since 11/12)

-53-

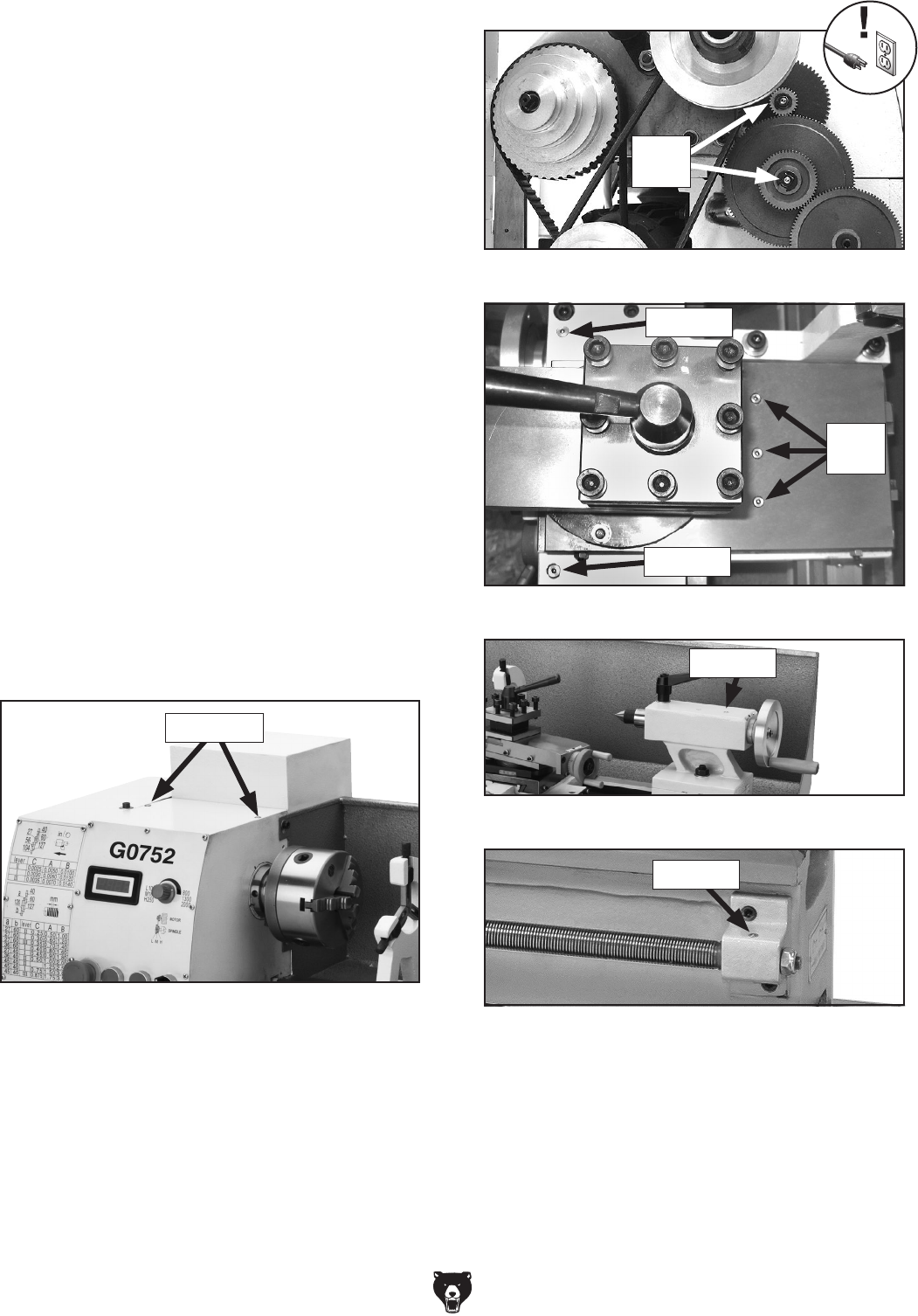

Figure 80. Change gear ball oilers.

Ball Oilers

Oil Type .... Grizzly T23963 or ISO 32 Equivalent

Oil Amount ................................1 or 2 Squirts/Fill

Lubrication Frequency ................................. Daily

This lathe has 10 ball oilers that should be oiled

on a daily basis before beginning operation.

Proper lubrication of ball oilers is done with a

pump-type oil can that has a plastic or rubber-

ized cone tip. We do not recommend using metal

needle or lance tips, as they can push the ball too

far into the oiler, break the spring seat, and lodge

the ball in the oil galley.

Lubricate the ball oilers before and after machine

use, and more frequently under heavy use. When

lubricating ball oilers, first clean the outside sur-

face to remove any dust or grime. Push the tip of

the oil can nozzle against the ball oiler to create

a hydraulic seal, then pump the oil can once or

twice. If you see sludge and contaminants coming

out of the lubrication area, keep pumping the oil

can until the oil runs clear. When finished, wipe

away any excess oil.

Refer to Figures 79–83 to identify the location of

each ball oiler.

Figure 79. Spindle bearing ball oilers.

Ball Oilers

Ball

Oilers

Figure 83. Leadscrew end bearing ball oilers.

Figure 82. Tailstock ball oiler.

Figure 81. Carriage and cross slide ball oilers.

Ball

Oilers

Ball Oiler

Ball Oiler

Ball Oiler

Ball Oiler