Model G0602/G0752 (Mfg. Since 11/12)

-47-

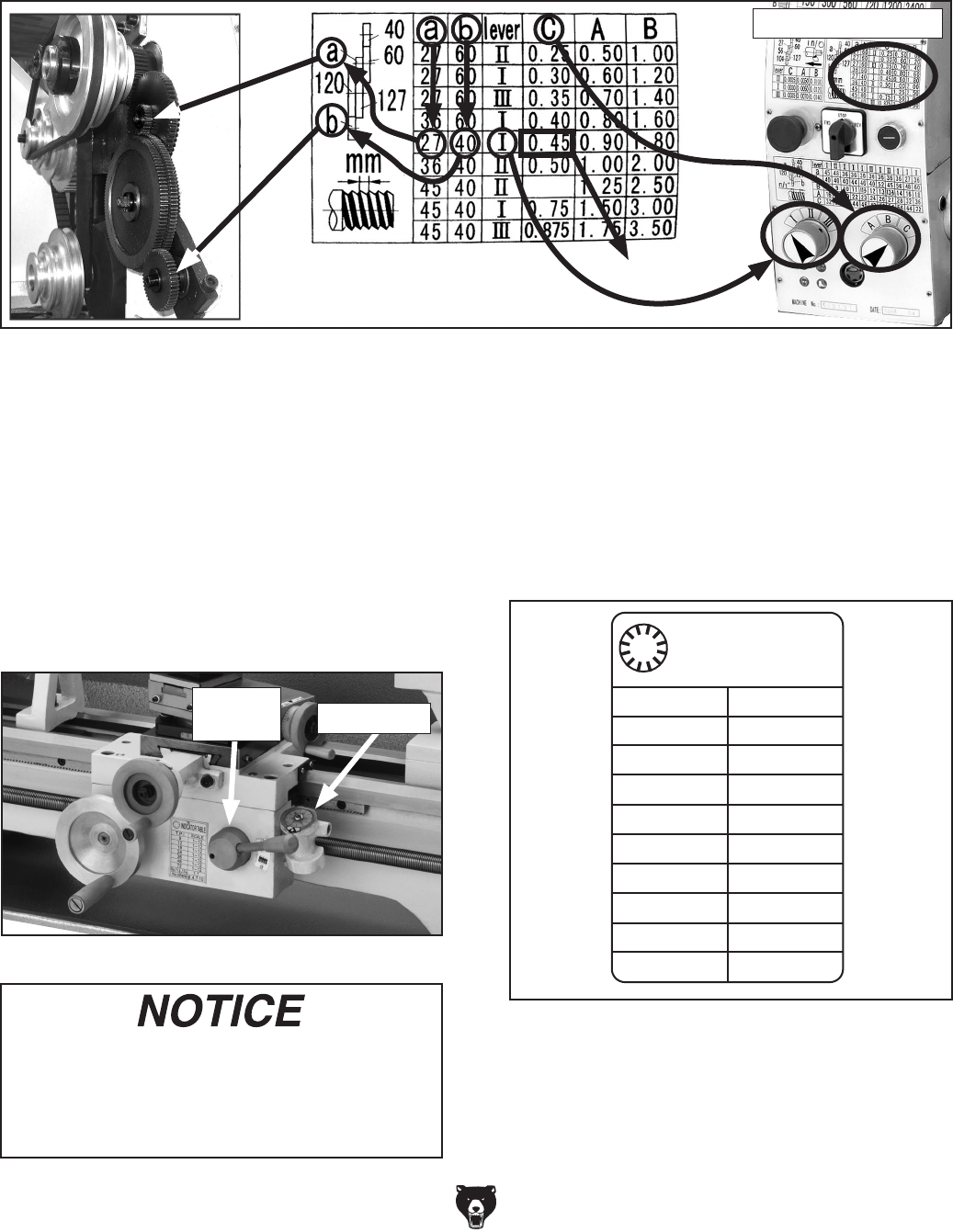

To set the lathe to cut 0.45 TPmm threads:

The steps for setting up the lathe for threading metric threads are the same as those for inch threads. Follow

the instructions on Page 46 for setting the thread pitch to 64 TPI, and refer to the chart below.

Note: Since this lathe has an inch leadscrew,

do not use the thread dial when cutting metric

threads. Instead you must leave the half nut

engaged from the beginning until the threading

operation is complete.

Apron Threading Controls

The half nut lever engages the carriage with the

leadscrew, which moves the carriage and cutting

tool along the length of the workpiece for thread-

ing and power feed operations (see Figure 64).

The numbers on the thread dial are used with the

thread dial chart to show when to engage the half

nut during inch threading. The thread dial num-

bers are not used when cutting metric threads,

since this lathe has an inch leadscrew.

When threading, we recommend using the

slowest speed possible and avoiding deep

cuts, so you are able to disengage the half

nut when required and prevent an apron

crash!

Figure 64. Half nut lever and thread dial.

Thread Dial

Half Nut

Lever

Thread Dial Chart

Find the TPI (threads per inch) that you want

to cut in the left column of the thread dial chart

(see Figure 65), then reference the dial number

to the right of it. The dial numbers indicate when

to engage the half nut for a specific thread pitch.

The thread dial chart can also be found on the

carriage beside the half nut lever.

Indicator Table

9

TPI SCALE

12

18

24

36

48

72

9½,11½, ,13½

1-12

1-12

1-12

1-12

1-12

1-12

1-12

1.7

1.4.7.10

Other TPI

Figure 65. Thread dial chart.

Figure 63. Metric threading setup.

= 0.45 TPmm

Metric Thread Chart