Model G0602/G0752 (Mfg. Since 11/12)

-39-

The follow rest mounts to the saddle with two cap

screws (see Figure 47). It is used on long, slender

parts to prevent workpiece deflection from cutting

tool pressure during operation. Adjust the follow

rest fingers in the same manner as the those on

the steady rest.

Note: To reduce the effects of friction, lubricate

the finger tips with generous anti-sieze lubricant

during operation.

Figure 47. Follow rest attachment.

Cap

Screws

Follow Rest

The carriage and cross slide have locks that can

be tightened to provide additional rigidity during

operation, especially during heavy cuts.

See Figure 48 to identify the locations of the

locks for each device.

Carriage & Slide

Locks

Figure 48. Carriage and cross slide locks.

Cross Slide

Lock

Carriage

Lock

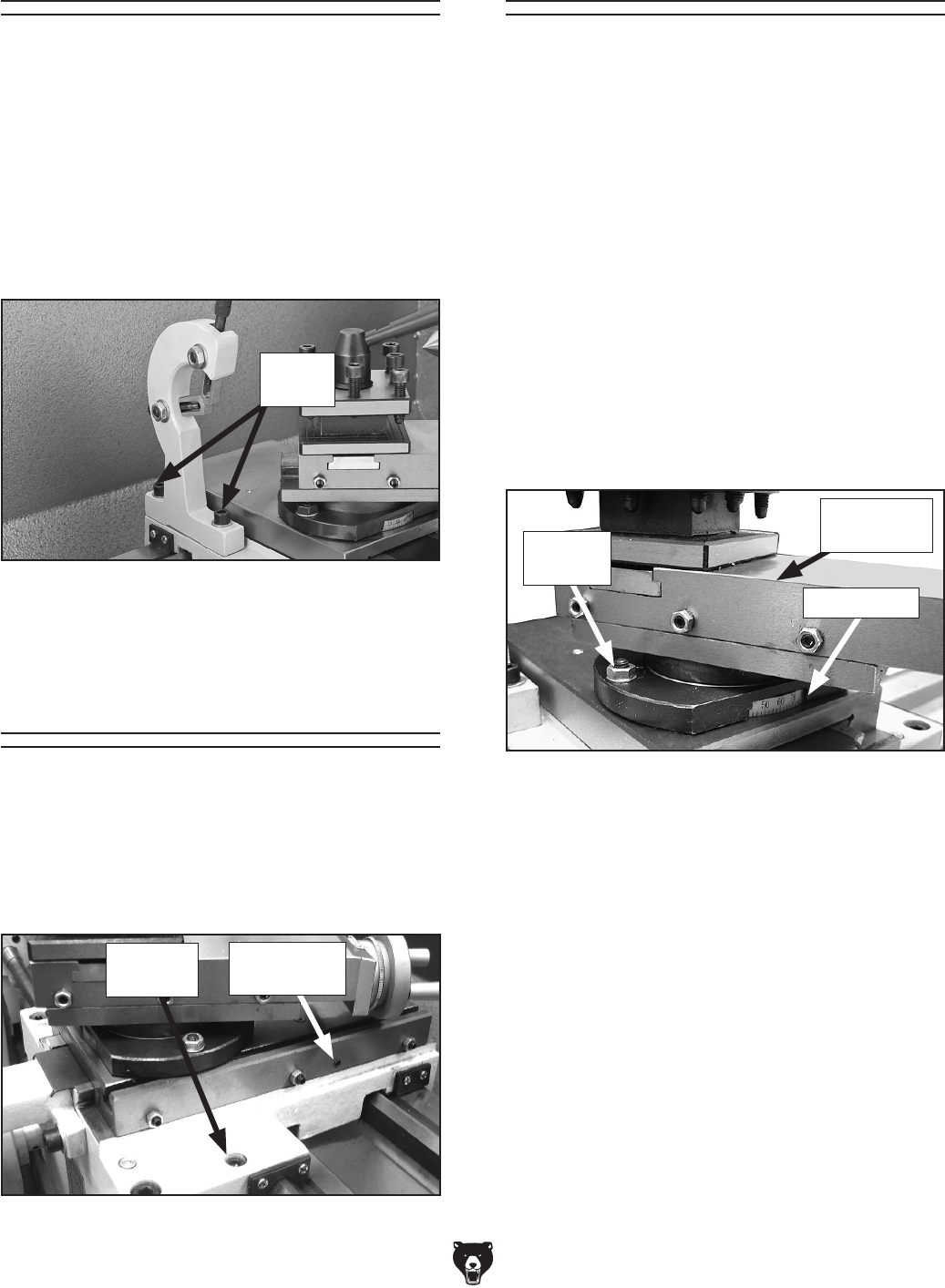

The compound rest handwheel has an indirect-

read graduated scale. This means the distance

shown on the scale represents the actual distance

the tool moves. The base of the compound rest

has another graduated scale used for setting the

cutting tool to a specific angle.

Graduated Dial

Increments ............................... 0.001" (0.025mm)

One Full Revolution ..................... 0.04" (1.02mm)

Tool Needed Qty

Open-End Wrench 14mm .................................. 1

To set the compound rest at a certain angle:

1. Loosen the two hex nuts at the base of the

compound rest (1 of 2 shown in Figure 49).

Compound Rest

2. Rotate the rest to the desired angle, as

indicated by the scale at the base,

then retighten the two hex nuts.

Tip: The first time you set the angle of the

compound rest for cutting threads, mark the

location on the cross slide as a quick refer-

ence point. This will allow you to quickly

return the compound rest to that exact angle

the next time you need to cut threads.

Figure 49. Compound rest.

Compound

Rest

Angle Scale

Hex Nut

(1 of 2)