-62-

Model G0602/G0752 (Mfg. Since 11/12)

The clamping pressure of the half nut is fully

adjustable with a gib that can be loosened or

tightened by two set screws. Use this procedure

to adjust the half nut if it becomes loose from

wear, or it is too tight for your preferences. A half

nut that is too loose will make it difficult to produce

accurate work; one that is too tight will increase

the rate of wear on itself and the leadscrew.

Tools Needed Qty

Open-End Wrench 8mm.................................... 1

Hex Wrench 5mm .............................................. 1

Hex Wrench 2.5mm ........................................... 1

To adjust the half nut:

1. DISCONNECT LATHE FROM POWER!

2. Disengage the half nut, then remove the

thread dial.

3. Loosen the two adjustment hex nuts shown

in Figure 91, then adjust the set screws in

small, even increments so one end of the gib

does not become tighter than the other.

Half Nut Adjustment

Half-Nut

4. Engage/disengage the half nut several times

and notice how it feels. The adjustment is

correct when the half nut has a slight drag

while opening and closing. The movement

should not be too stiff or too sloppy.

5. Repeat Steps 3–4, if necessary, until you are

satisfied with the half nut pressure.

6. While keeping the set screws from moving,

re-tighten the hex nuts, then re-install the

thread dial.

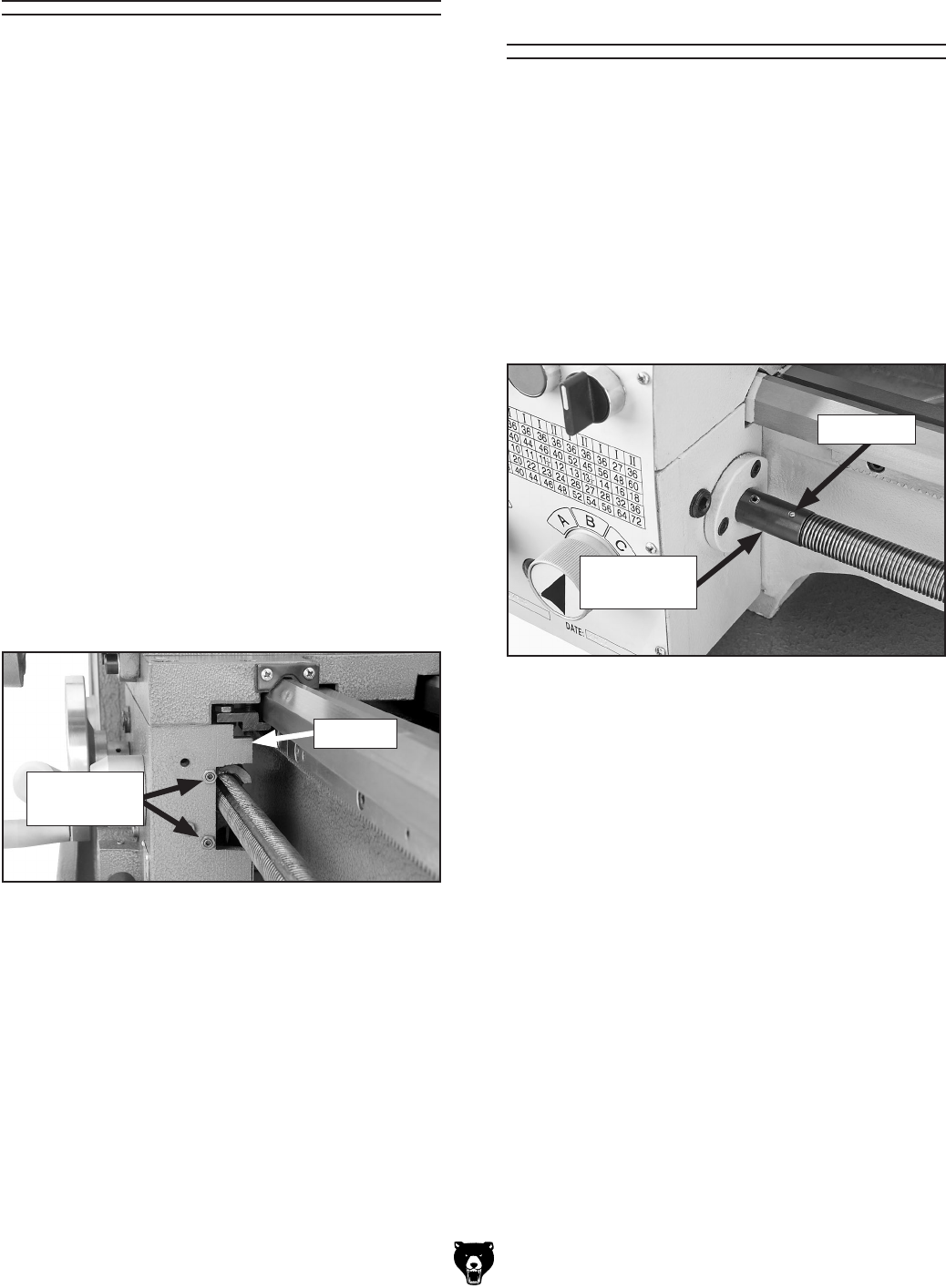

Figure 91. Typical half nut gib adjustment.

Adjustment

Fasteners

Leadscrew Shear Pin

Replacement

The longitudinal leadscrew is secured to the feed

rate gearing in the headstock with the use of a

soft-metal shear pin (see Figure 92). The shear

pin is designed to break and disengage power

to the leadscrew to help protect more expensive

lathe components if you crash your carriage or

take too large of a cut and overload the lathe.

Contact Grizzly Customer Service at (570) 546-

9663 to order a replacement shear pin (Part #

P0602815).

Tools Needed Qty

Hammer ............................................................. 1

Punch 2.5mm .................................................... 1

To replace the shear pin:

1. DISCONNECT LATHE FROM POWER!

2. Rotate the leadscrew so the shear pin faces

up and down. If the connecting collar rotates

independently from the leadscrew, then

rotate the collar so the shear pin holes align

with those in the leadscrew.

3. Use the punch and hammer to drive out the

pieces of the old shear pin.

4. Make sure the holes in the collar and

leadscrew are aligned, then tap the new

shear pin completely through the holes in the

collar and leadscrew.

Figure 92. Longitudinal leadscrew shear pin.

Shear Pin

Connecting

Collar