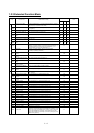

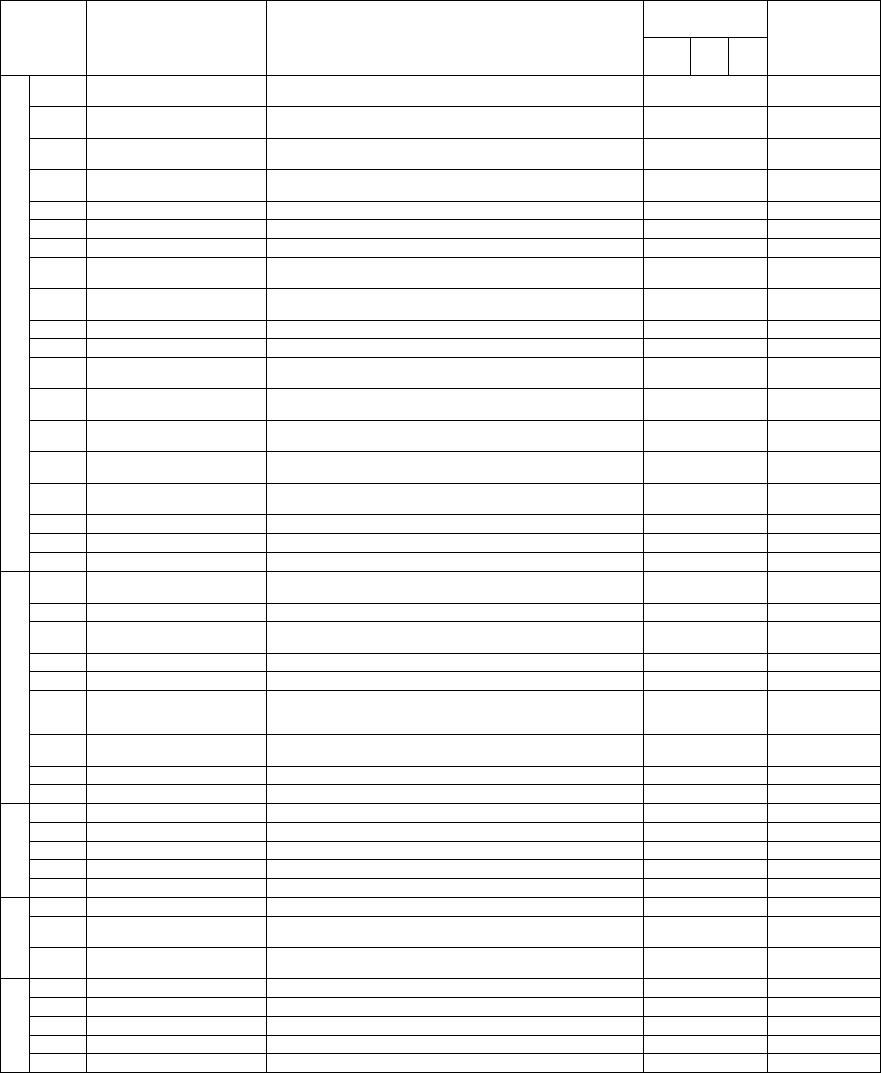

1 - 12

Default

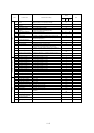

Code Function name Monitored data or setting

_FF _FEF _FUF

Note

C038

Low-current indication signal

output mode selection

00 (output during acceleration/deceleration and constant-speed operation),

01 (output only during constant-speed operation)

01

C039

Low-current indication signal

detection level

0.0 to 2.00 x "rated current" (A)

Rated current of

inverter

C040 Overload signal output mode

00 (output during acceleration/deceleration and constant-speed operation),

01 (output only during constant-speed operation)

01

C041 Overload level setting 0.0 to 2.00 x "rated current" (A)

Rated current of

inverter

C042 Frequency arrival setting for accel. 0.00 to 99.99, 100.0 to 400.0 (Hz) 0.00

C043 Frequency arrival setting for decel. 0.00 to 99.99, 100.0 to 400.0 (Hz) 0.00

C044 PID deviation level setting 0.0 to 100.0 (%) 3.0

C045

Frequency arrival setting for

acceleration (2)

0.00 to 99.99, 100.0 to 400.0 (Hz) 0.00

C046

Frequency arrival setting for

deceleration (2)

0.00 to 99.99, 100.0 to 400.0 (Hz) 0.00

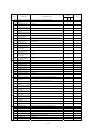

C052 Maximum PID feedback data 0.0 to 100.0 (%) 100.0

C053 Minimum PID feedback data 0.0 to 100.0 (%) 0.0

C055

Over-torque (forward-driving) level

setting

0. to 200. (%) 100.

C056

Over-torque (reverse

regenerating) level setting

0. to 200. (%) 100.

C057

Over-torque (reverse driving) level

setting

0. to 200. (%) 100.

C058

Over-torque (forward

regenerating) level setting

0. to 200. (%) 100.

C061

Electronic thermal warning level

setting

0. to 100. (%) 80.

C062 Alarm code output 00 (disabling), 01 (3 bits), 02 (4 bits) 00

C063 Zero speed detection level 0.00 to 99.99, 100.0 (Hz) 0.00

Levels and output terminal status

C064 Heat sink overheat warning level

0. to 200.0 (°C)

120.

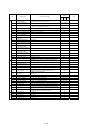

C071 Communication speed selection

02 (loopback test), 03 (2,400 bps), 04 (4,800 bps), 05 (9,600 bps), 06

(19,200 bps)

04

C072 Node allocation 1. to 32. 1.

C073

Communication data length

selection

7 (7 bits), 8 (8 bits) 7

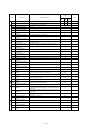

C074 Communication parity selection 00 (no parity), 01 (even parity), 02 (odd parity) 00

C075 Communication stop bit selection 1 (1 bit), 2 (2 bits) 1

C076

Selection of the operation after

communication error

00 (tripping), 01 (tripping after decelerating and stopping the motor), 02

(ignoring errors), 03 (stopping the motor after free-running), 04

(decelerating and stopping the motor)

02

C077

Communication timeout limit

before tripping

0.00 to 99.99 (s) 0.00

C078 Communication wait time 0. to 1000. (ms) 0.

Communication function

C079 Communication mode selection 00(ASCII), 01(Modbus-RTU) 00

C081 [O] input span calibration 0. to 9999., 1000 to 6553(10000 to 65530) Factory setting

C082 [OI] input span calibration 0. to 9999., 1000 to 6553(10000 to 65530) Factory setting

C083 [O2] input span calibration 0. to 9999., 1000 to 6553(10000 to 65530) Factory setting

C085 Thermistor input tuning 0.0 to 999.9, 1000. Factory setting

Adjustment

C091 Debug mode enable (Do not change this parameter, which is intended for factory adjustment.) 00

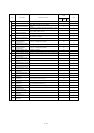

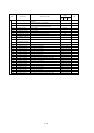

C101 Up/Down memory mode selection 00 (not storing the frequency data), 01 (storing the frequency data) 00

C102 Reset mode selection

00 (resetting the trip when RS is on), 01 (resetting the trip when RS is off), 2

(enabling resetting only upon tripping [resetting when RS is on])

00

Others

C103 Restart mode after reset

00 (starting with 0 Hz), 01 (starting with matching frequency), 02 (restarting

with active matching frequency),03(resetting only trip)

00

C105 FM gain adjustment 50. to 200. (%) 100.

C106 AM gain adjustment 50. to 200. (%) 100.

C107 AMI gain adjustment 50. to 200. (%) 100.

C109 AM bias adjustment 0. to 100. (%) 0.

Meter

adjustment

C110 AMI bias adjustment 0. to 100. (%) 20.