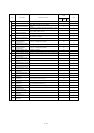

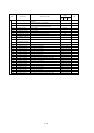

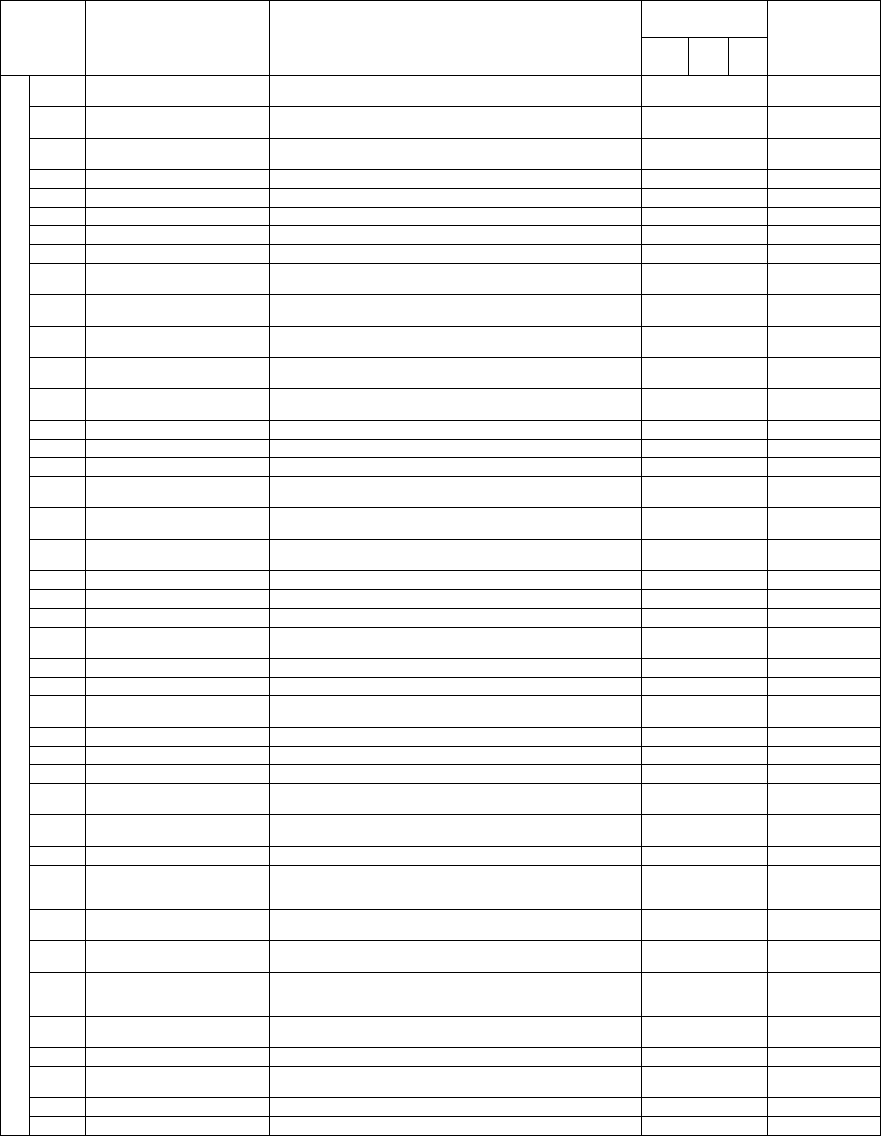

1 - 16

Default

Code Function name Monitored data or setting

_FF _FEF _FUF

Note

P001

Operation mode on expansion card

1 error

00 (tripping), 01 (continuing operation) 00

P002

Operation mode on expansion card

2 error

00 (tripping), 01 (continuing operation) 00

P011

Encoder pulse-per-revolution

(PPR) setting

128. to 9999., 1000 to 6553(10000 to 65535) (pulses) 1024.

P012 Control pulse setting 00 (ASR), 01 (APR), 02 (APR2), 03 (HAPR) 00

P013 Pulse train mode setting 00 (mode 0), 01 (mode 1), 02 (mode 2) 00

P014 Home search stop position setting 0. to 4095. 0.

P015 Home search speed setting "start frequency" to "maximum frequency" (up to 120.0) (Hz) 5.00

P016 Home search direction setting 00 (forward), 01 (reverse) 00

P017

Home search completion range

setting

0. to 9999., 1000 (10000) (pulses) 5.

P018

Home search completion delay

time setting

0.00 to 9.99 (s) 0.00

P019

Electronic gear set position

selection

00 (feedback side), 01 (commanding side) 00

P020

Electronic gear ratio numerator

setting

0. to 9999. 1.

P021

Electronic gear ratio denominator

setting

0. to 9999. 1.

P022 Feed-forward gain setting 0.00 to 99.99, 100.0 to 655.3 0.00

P023 Position loop gain setting 0.00 to 99.99, 100.0 0.50

P024 Position bias setting -204 (-2048.) / -999. to 2048. 0.

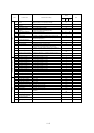

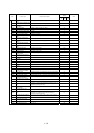

P025

Temperature compensation

thermistor enable

00 (no compensation), 01 (compensation) 00

P026

Over-speed error detection level

setting

0.0 to 150.0 (%) 135.0

P027

Speed deviation error detection

level setting

0.00 to 99.99, 100.0 to120.0 (Hz) 7.50

P028 Numerator of motor gear ratio 0. to 9999. 1.

P029 Denominator of motor gear ratio 0. to 9999. 1.

P031 Accel/decel time input selection 00 (digital operator), 01 (option 1), 02 (option 2), 03 (easy sequence) 00

P032

Positioning command input

selection

00 (digital operator), 01 (option 1), 02 (option 2) 00

P033 Torque command input selection 00 (O terminal), 01 (OI terminal), 02 (O2 terminal), 03 (digital operator) 00

P034 Torque command setting 0. to 200. (%) 0.

P035

Polarity selection at the torque

command input via O2 terminal

00 (as indicated by the sign), 01 (depending on the operation direction) 00

P036 Torque bias mode 00 (disabling the mode), 01 (digital operator), 02 (input via O2 terminal) 00

P037 Torque bias value -200. to +200. (%) 0.

P038 Torque bias polarity selection 00 (as indicated by the sign), 01 (depending on the operation direction) 00

P039

Speed limit for torque-controlled

operation (forward rotation)

0.00 to "maximum frequency" (Hz) 0.00

P040

Speed limit for torque-controlled

operation (reverse rotation)

0.00 to "maximum frequency" (Hz) 0.00

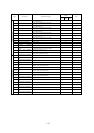

P044 DeviceNet comm watchdog timer 0.00 to 99.99 (s) 1.00

P045

Inverter action on DeviceNet comm

error

00 (tripping), 01 (tripping after decelerating and stopping the motor), 02

(ignoring errors), 03 (stopping the motor after free-running), 04

(decelerating and stopping the motor)

01

P046

DeviceNet polled I/O: Output

instance number

20, 21, 100 21

P047

DeviceNet polled I/O: Input

instance number

70, 71, 101 71

P048

Inverter action on DeviceNet idle

mode

00 (tripping), 01 (tripping after decelerating and stopping the motor), 02

(ignoring errors), 03 (stopping the motor after free-running), 04

(decelerating and stopping the motor)

01

P049

DeviceNet motor poles setting for

RPM

0, 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, 24, 26, 28, 30, 32, 34, 36, 38

(poles)

0

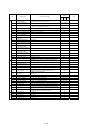

P055 Pulse-string frequency scale 1.0 to 50.0 (kHz) 25.0

P056

Time constant of pulse-string

frequency filter

0.01 to 2.00 (s) 0.10

P057 Pulse-string frequency bias -100. to +100. (%) 0.

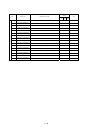

Optional functions

P058 Pulse-string frequency limit 0. to 100. (%) 100.