B-3

SP-100

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

OPERATION

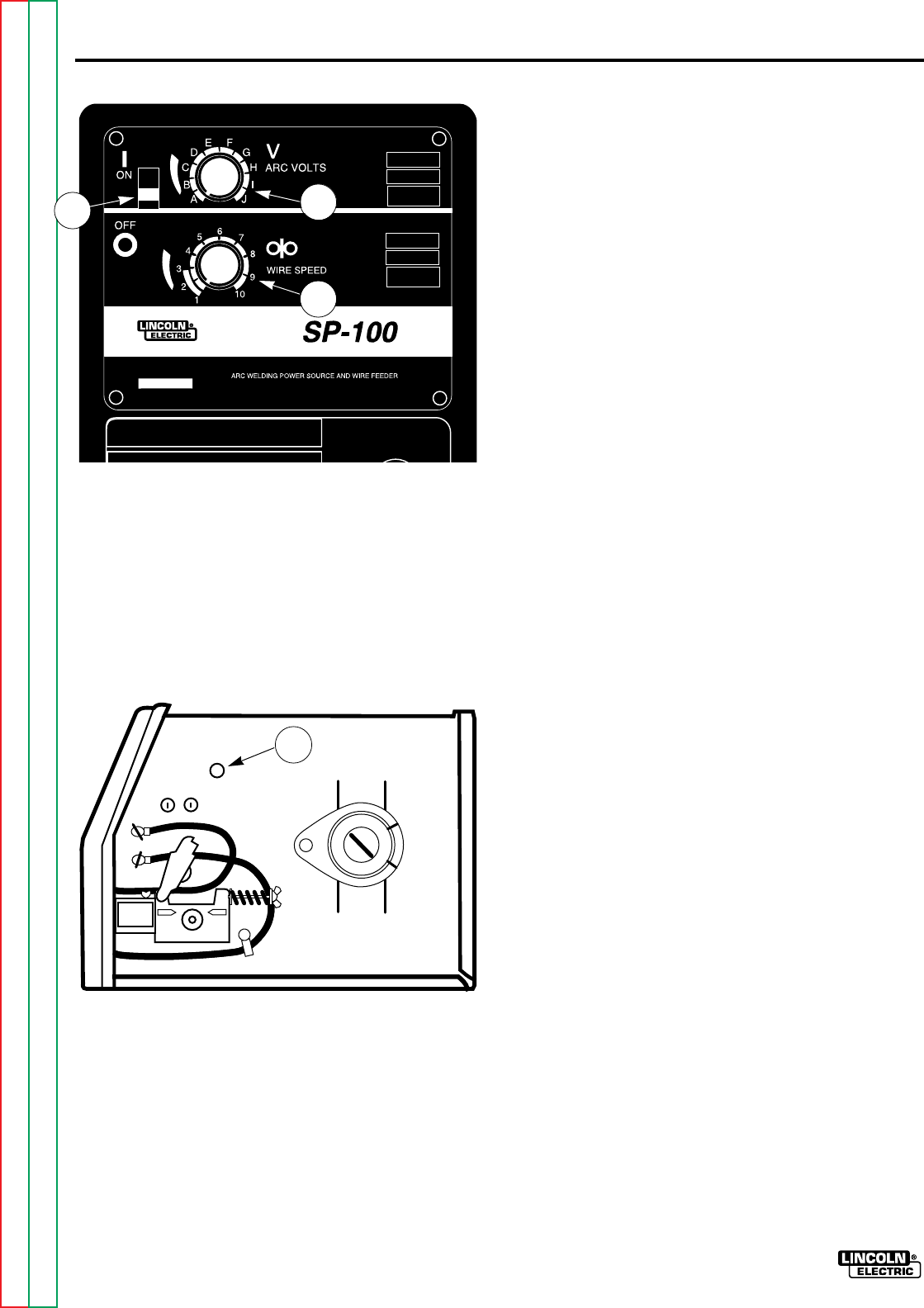

FIGURE B.1a

Refer to Figure B-1b.

4. Circuit Breaker - Protects machine from damage if

maximum output is exceeded. Button will extend

out when tripped (Manual reset).

FIGURE B.1b

WELDING OPERATIONS

PROCESS GUIDELINES

The SP-100 can be used for welding mild steel using

the GMAW, single pass, process which requires a

supply of shielding gas or it can be used for the self

shielded, Innershield electrode process.

The recommended gas and electrode for GMAW is

welding grade CO

2

gas and 0.025” (0 6 mm) diameter

Lincoln L-56 mild-steel welding wire [supplied on

121/2 Ib (6 kg) spools]. For 14 gauge (2,0 mm) and

thinner, CO

2

gas is recommended because it gives

equal or better performance than a blended gas at a

lower cost. A mixed gas consisting of 75 to 80% Argon

and 20 to 25% CO

2

is recommended for welding on

heavier gauge [12 gauge (2,5 mm) for example] steel.

The recommended electrode for the self-shielded

process is 0.035” (0,9 mm) diameter Lincoln

Innershield NR-211-MP on 10 Ib (4,5 kg) spools. This

electrode can be used for all position welding of 20

gauge through 5/16” (1 0 – 8,0 mm) thick steel [multi-

ple passes are required for 1/4” and 5/16” (6,0 and 8,0

mm)].

SEQUENCE OF OPERATION

WIRE LOADING

Refer to Figure B.2. and B.3.

The machine power switch should be turned to the

OFF (“O”) position before working inside the wire feed

enclosure.

The machine is shipped from the factory ready to

feed 8” (200 mm) diameter spools [2.2” (56 mm)

max. width]. These spools fit on a 2” (50 mm) diame-

ter spindle that has a built-in adjustable* friction brake

to prevent overrun of the spool and excess slack in

the wire. The thumb screw at the end of the shaft is

not intended to be loosened. It should be tightened full

clockwise. NOTE: If full tightening of the spindle

thumbscrew causes too much tension in the wire

spool, the thumb screw stop point should be

adjusted.

*Earlier spindle shafts did not include a set screw to

adjust brake friction. If a set screw is desired, order

Lincoln part number T12932-2.

Load an 8” (200 mm) diameter spool on the wire spool

spindle shown in Figure B.2.

To use 4” (100 mm) diameter spools, the 2” (50

mm) diameter spindle must be removed (See Figure

B.3). Remove the thumb screw at the end of the shaft

and remove the spindle. The spindle can be stored in

the wire feed compartment. A 4’ (100 mm) diameter

spool is mounted directly on the 5/8” (16 mm) diame-

ter shaft and held in place with the previously removed

thumb screw. Make certain that the thumbscrew is

3

2

1

4