SP-100

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

F-7

TROUBLESHOOTING & REPAIR

Observe Safety Guidelines

detailed in the beginning of this manual.

TROUBLESHOOTING GUIDE

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln

Electric Service Department for technical troubleshooting assistance before you proceed call 216-383-2531 or 1-800-833-9353.

CAUTION

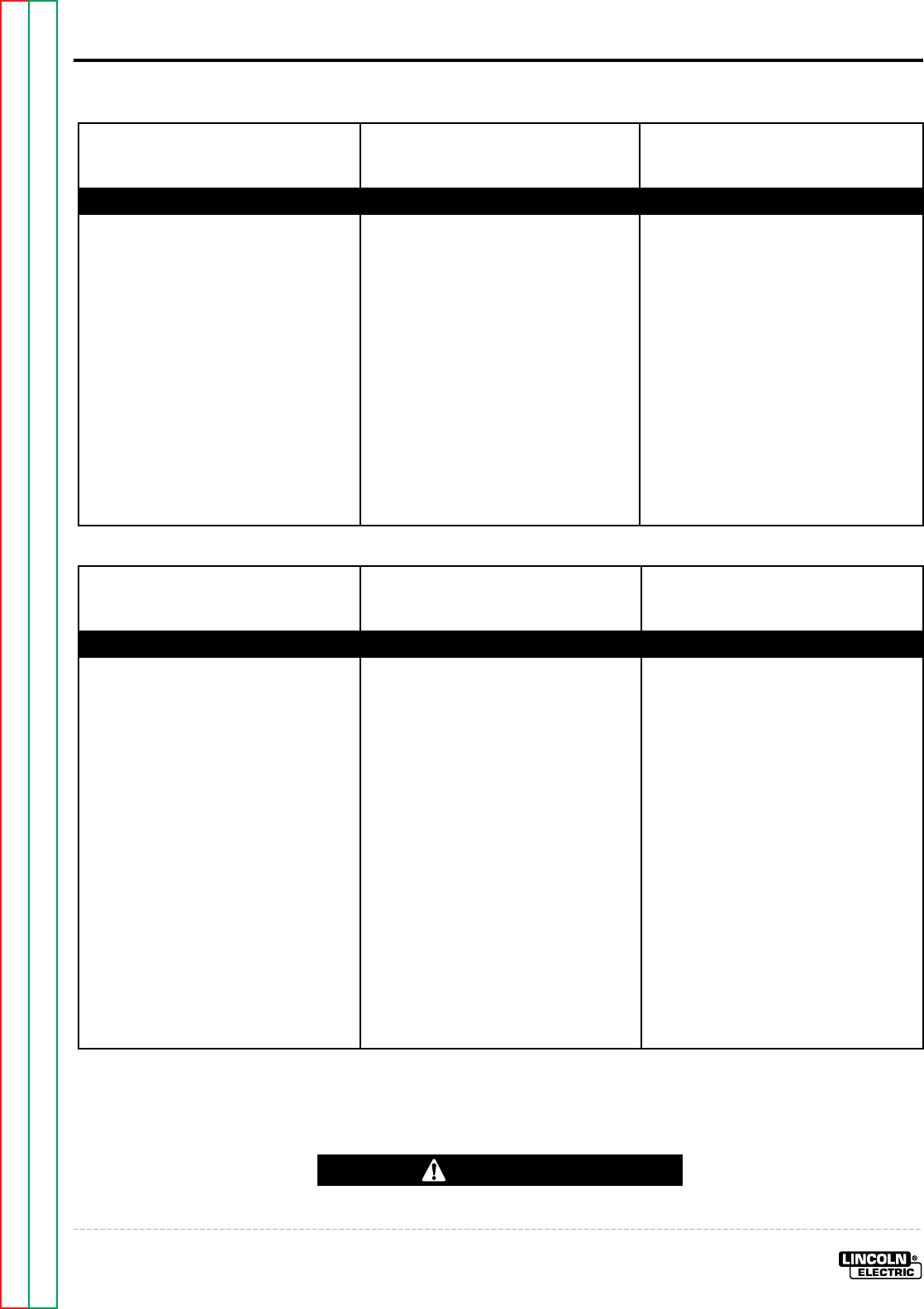

PROBLEMS

(SYMPTOMS)

Low or no gas flow when gun

trigger is pulled. Wire feed, weld

output and fan operate normally.

POSSIBLE AREAS OF

MISADJUSTMENT(S)

1. Check gas supply, flow regulator

and gas hoses.

2. Check gun connection to

machine for obstruction or leaky

seals.

RECOMMENDED

COURSE OF ACTION

1. Check for 115 vac at the gas

solenoid leads #7 to #32A. If the

correct voltage is present but

the solenoid does not activate,

replace solenoid. See wiring dia-

gram .

2. If voltage is not present at leads

#7 to #32A, remove main supply

power to machine. Test leads #7

and #32A for continuity (zero

ohms) to the control board.

3. Control board may be faulty.

Replace.

GAS FLOW PROBLEMS

PROBLEMS

(SYMPTOMS)

Arc is unstable – Poor starting

POSSIBLE AREAS OF

MISADJUSTMENT(S)

1. Check for correct input voltage

to machine – 115 vac.

2. Check for proper electrode

polarity for process.

3. Check gun tip for wear or dam-

age – Replace.

4. Check for proper gas and flow

rate for process.

5. Check work cable for loose or

faulty connections.

6. Check gun for damage or

breaks.

RECOMMENDED

COURSE OF ACTION

1. Check for correct open circuit

voltage (OCV) at machine’s out-

put terminals, 10 vdc to 28 vdc,

depending on arc voltage con-

trol setting. If correct OCV is

present check gun and work

cable.

2. If OCV is low, check output

capacitor and output diodes.

3. Check arc voltage control poten-

tiometer and associated wires

#205, #206 and #207 for loose

or broken connections. See

wiring diagram.

4. Control board may be faulty.

Replace.

WELDING PROBLEMS