SP-100

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

F-5

TROUBLESHOOTING & REPAIR

TROUBLESHOOTING GUIDE

Observe Safety Guidelines

detailed in the beginning of this manual.

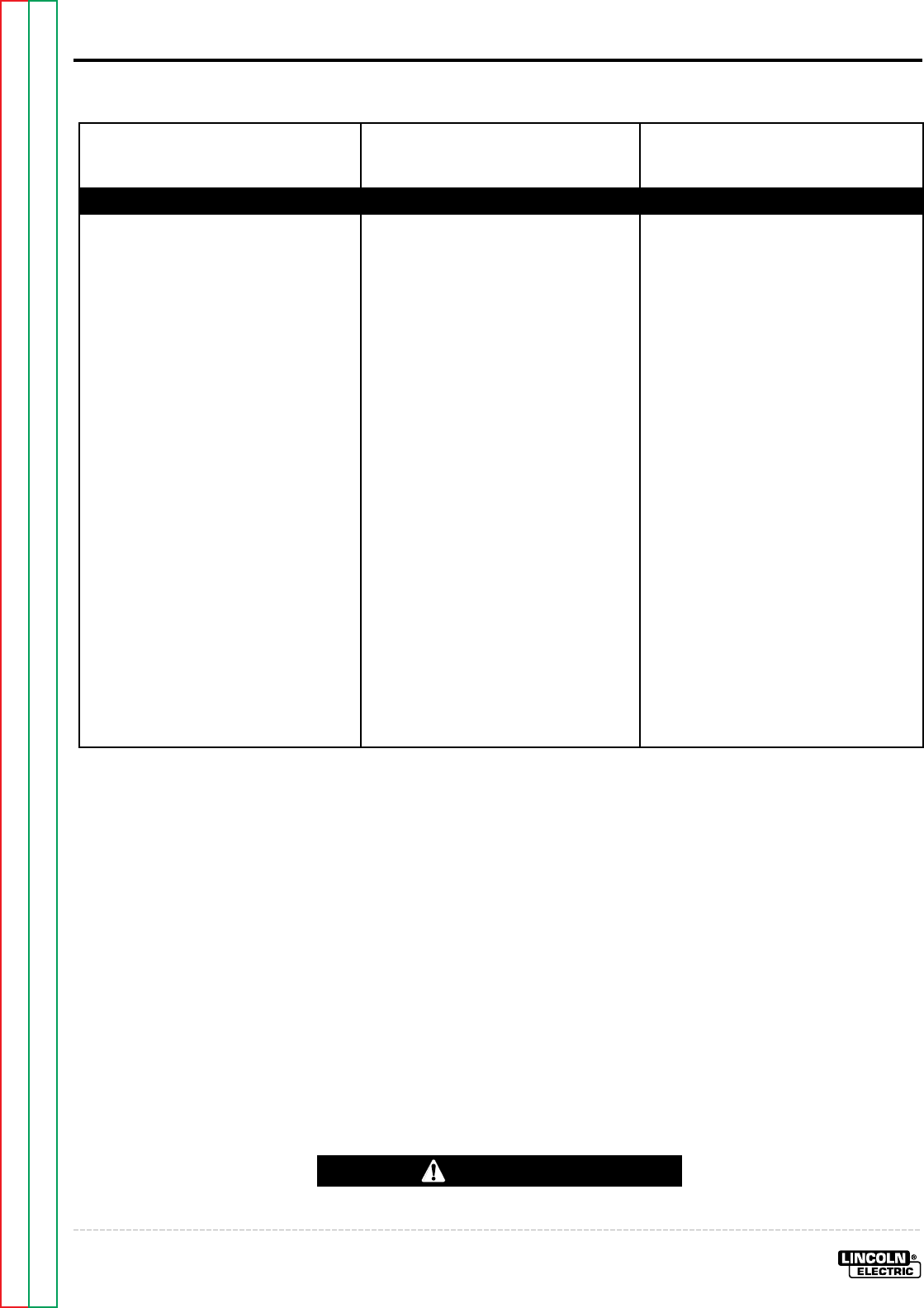

PROBLEMS

(SYMPTOMS)

CODE 9794 and ABOVE

No Wire feed, weld output or gas

flow when the gun trigger is pulled -

Fan operates normally.

POSSIBLE AREAS OF

MISADJUSTMENT(S)

1. Check the circuit breaker in the

machine – Located in the wire

drive compartment. Reset if

tripped.

2. The thermostat may be tripped

due to overheating. Let machine

cool. Weld within the duty cycle

or remove any air obstruction to

machine.

3. Wire feed motor may be over-

loaded – correct feeding prob-

lem.

4. Gun trigger may be faulty.

RECOMMENDED

COURSE OF ACTION

1. Check for 24 vac at plug 2J1 to

6J1 on the control board. If volt-

age is not present, check conti-

nuity of leads to fan motor. If

leads are OK, replace fan motor.

See Figure F.1

2. Remove main power supply to

SP-100. With gun trigger pulled

check for continuity (zero ohms)

from 8J2 (lead #213) to 9J2

(lead #211) at harness plug. If

zero ohms is indicated then trig-

ger circuit is OK. See Figure

F.1.

3. If an open circuit or high resis-

tance is indicated in Step 2, then

check leads #211, #212 and

#213 for loose or broken con-

nections. Also check the normal-

ly closed thermostat mounted on

the diode heat sink assembly.

4. The control board may be faulty

– Replace.

OUTPUT PROBLEMS

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln

Electric Service Department for technical troubleshooting assistance before you proceed call 216-383-2531 or 1-800-833-9353.

CAUTION