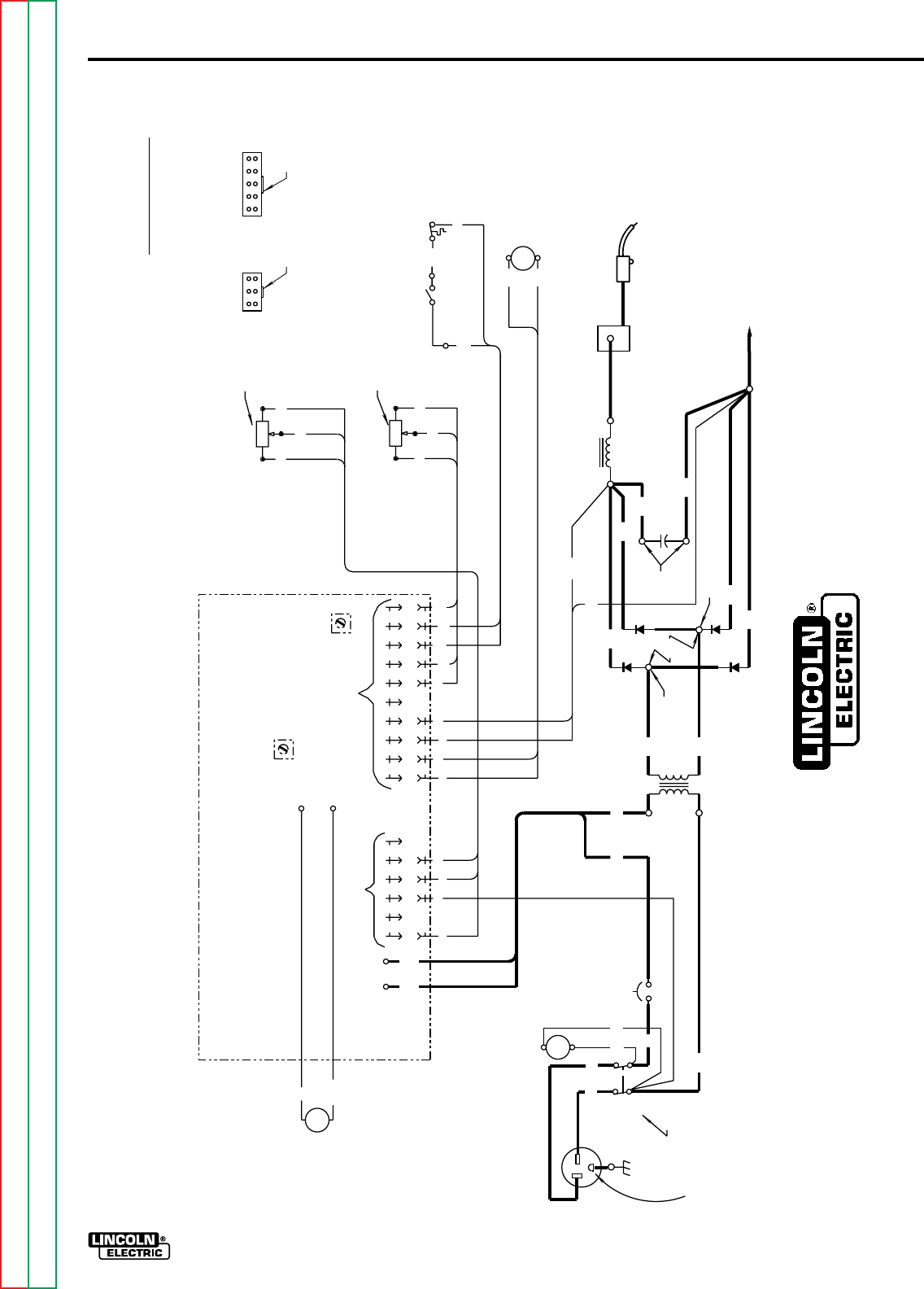

G-3

SP-100

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

WIRING DIAGRAMS

L1

L2

31

32

32 531

TO GROUND

PER NATIONAL

ELECTRICAL CODE

S1

SWITCH

202

201

D1

D3

D2

D4

204

204

204

203

203

203

C1

59,000 mf

40V

203

204

-

+

OUTPUT CHOKE

GUN CABLE

CONDUCTOR

BLOCK

TO

WORK

ELECTRICAL SYMBOLS PER E1537

CIRCUIT

BREAKER

31A

LEAD COLOR CODE:

B-BLACK

W-WHITE

123

456

LATCH

31

FAN

MOTOR

1234

LATCH

5

678910

J1

J2

CAVITY NUMBERING SEQUENCE

( COMPONENT SIDE OF BOARD )

12

3

4

56

1234

5

6

7

8910

GAS

SOLENOID

7

32A

CONTROL P.C. BOARD

539

541

207

205

206

541

539

203

204

203

209

213

208

211

531

31A

T1

WIRE FEED MOTOR

212

213

211

GUN TRIGGER THERMOSTAT

(MOUNTED TO

DIODE HEATSINK)

+

208

209

203

5K

WIRE SPEED

205

206

207

5K

32

( J1 )

( J2 )

*

*

*

CONNECTOR CAVITY NUMBER

ARC VOLTAGE

R1

R2

(W)

(B)

7

32A

HI

LO

N.B.

N.A.

N.C.

N.C.

N.C. COMPONENT VIEWED FROM REAR.

ON-OFF

N.C.

15427

8-1-91D

SP WELDERS

WIRING DIAGRAM

15427

M

M

N.D.

N.D.

N.A. DIODES D1 & D3 ARE MOUNTED ON THE

OUTSIDE HEATSINK.

N.B. DIODES D2 & D4 ARE MOUNTED ON THE

INSIDE HEATSINK, WHICH IS CLOSEST TO THE

CENTER PANEL.

N.D. BOLTED ALUMINUM CONNECTIONS REQUIRE JOINT

COMPOUND. SEE OPERATING MANUAL WHEN

REATTACHING.

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

The specific diagram for a particular code is pasted inside the machine on one of the enclosure panels.

SP-100 WIRING DIAGRAM: CODES Below 9794