SP-100

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

F-6

TROUBLESHOOTING & REPAIR

Observe Safety Guidelines

detailed in the beginning of this manual.

TROUBLESHOOTING GUIDE

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln

Electric Service Department for technical troubleshooting assistance before you proceed call 216-383-2531 or 1-800-833-9353.

CAUTION

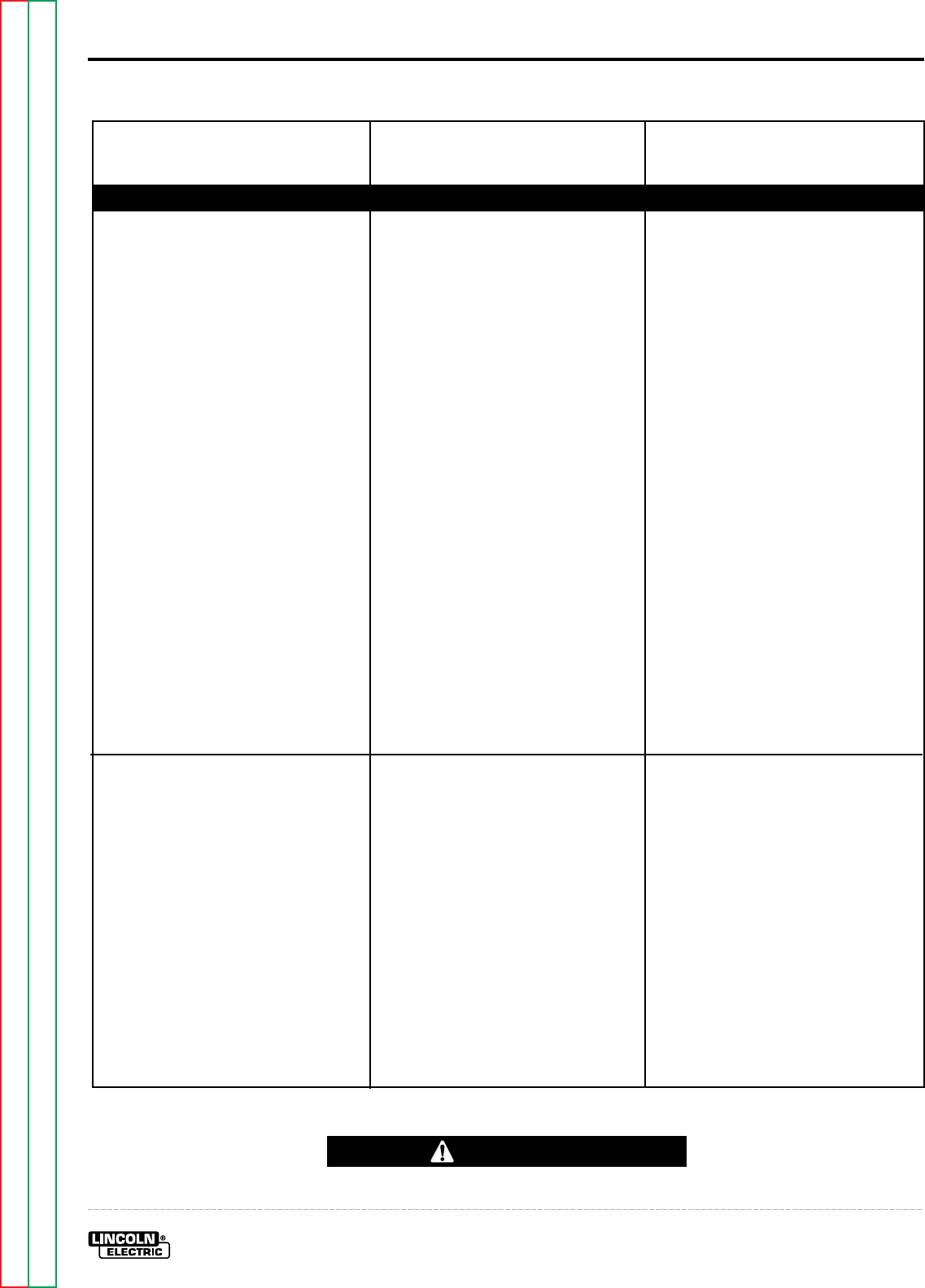

PROBLEMS

(SYMPTOMS)

No wire feed when gun trigger is

pulled. Fan runs, gas flows and

machine has correct open circuit

voltage (28 vdc maximum) – weld

output.

Wire feed speed motor runs very

fast. Weld output, gas flow and fan

operate normally.

POSSIBLE AREAS OF

MISADJUSTMENT(S)

1. If the wire drive motor is running

check to see if the correct wire

is in the machine.

2. If the wire drive motor is running

make sure that the correct drive

rolls are installed in the

machine.

3. Check for clogged cable liner or

feeding problems.

1. Make sure that the wire speed

control is not set at maximum.

RECOMMENDED

COURSE OF ACTION

1. Check for a DC voltage at wire

drive motor armature (leads

#539 to #541). The voltage

should be between 2 vdc and 10

vdc. This voltage will vary with

the wire speed control setting. If

the correct voltage is present,

the drive motor may be faulty.

Replace. See wiring diagram.

2. If the motor armature voltage is

not present, then check for OCV

at leads #203 (3J2) and #204

(4J2) on the control board. If

correct voltage is present, go to

Step 3. If OCV is not present at

leads #203 and #204, check

continuity (zero ohms) of leads.

3. If the motor armature voltage is

not present, then check the wire

speed control potentiometer and

associated wires #208, #209

and #203 for faulty connections.

4. The control board may be faulty.

Replace.

1. Remove main supply power to

machine. Disconnect plug J2

from the control board. Test the

resistance from lead #539 (2J2)

in the harness plug to the wire

feed motor case. If the resis-

tance is below 500,000 ohms,

replace the drive motor.

2. Check the wire speed control

potentiometer and associated

wires #208, #209 and #203 for

loose or broken connections.

3. The control board may be faulty.

Replace.

FEEDING PROBLEMS