F-23

TROUBLESHOOTING AND REPAIR

F-23

To further check the drive motor:

12. Remove input power (115VAC)

from the LN-8.

13. Locate and remove leads #539

and #541 from the control board,

see Figure F.5.

14. Locate and remove leads #626

and #627 from the relay board.

15. Using the ohmmeter, measure the

resistances per Table F.3.

16. If the motor resistance test is

good, proceed to the Motor

Applied Voltage Test.

MOTOR APPLIED

VOLTAGE TEST

1. Carefully connect the isolated

120VDC supply (supply turned off)

to motor leads #626 and #627, see

Figure F.5.

2. Carefully connect the variable 0 to

120VDC supply (supply turned off)

to motor leads #539 and #541.

3. Apply field voltage first (leads #626

and #627) to the motor. Then

slowly apply the armature voltage

at leads #539 and #541.

4. The motor should run and the

speed should vary with changes to

the armature voltage.

5. If the motor does NOT run and

change speed correctly, the motor

or gear box may be faulty.

6. To stop the motor, remove the

armature voltage first, leads #539

and #541.

AFTER TESTING

1. Replace motor leads.

2. Install the screws that secure the

left side cover assembly.

3. If disengaged, engage the drive

rolls.

4. If removed, feed the electrode

back into the wire drive unit.

DRIVE MOTOR TEST (continued)

LN-8

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

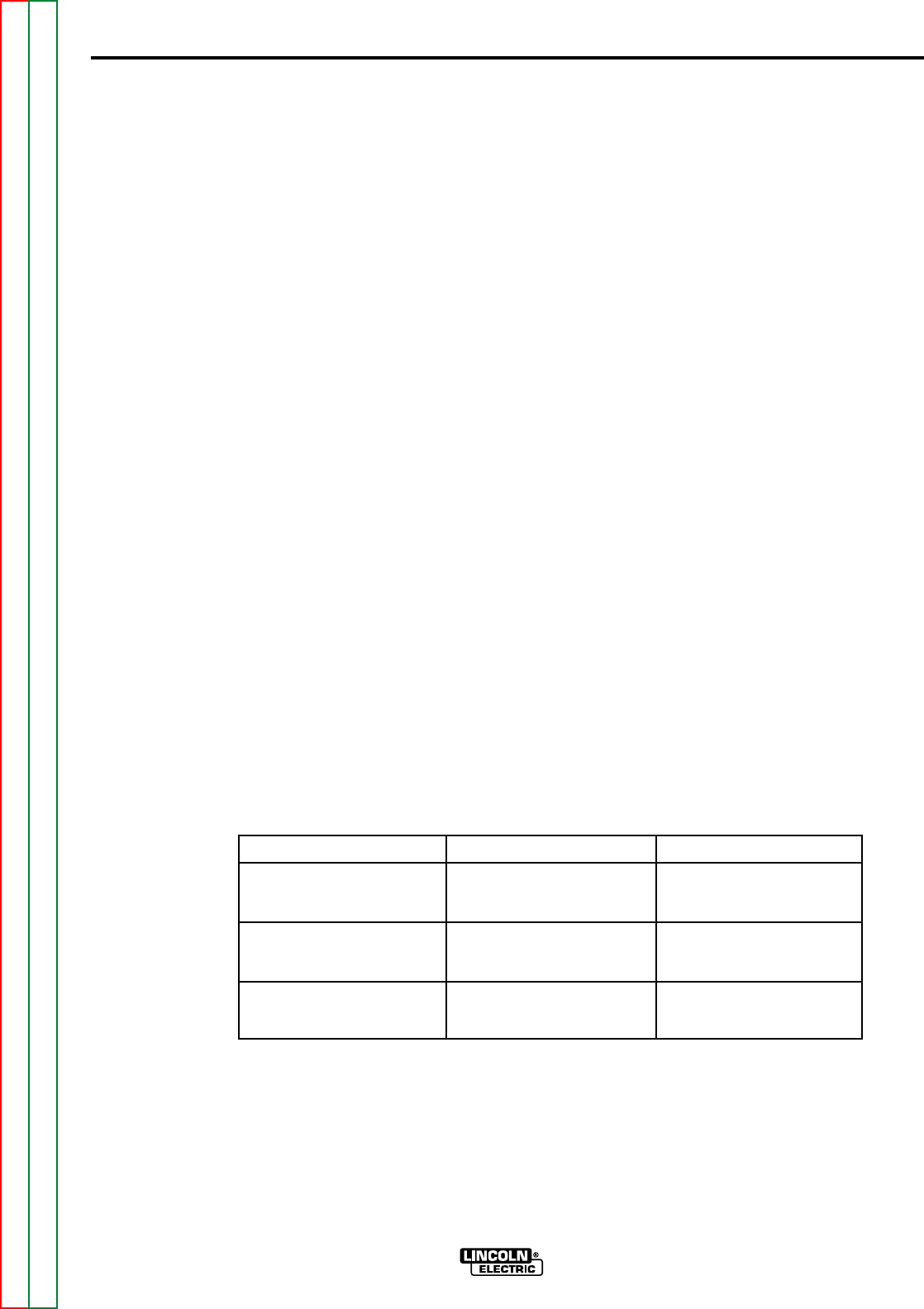

TEST POINTS RESISTANCE DC VOLTAGE

Lead #539 to #541 3 to 5 ohms 0 to 90VDC

Armature

Lead #626 to #627 750 to 950 ohms 90 to 120VDC

Field Winding

All leads to 500,000 ohms N/A

motor shell min.

TABLE F.3 – DRIVE MOTOR TEST POINTS