Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

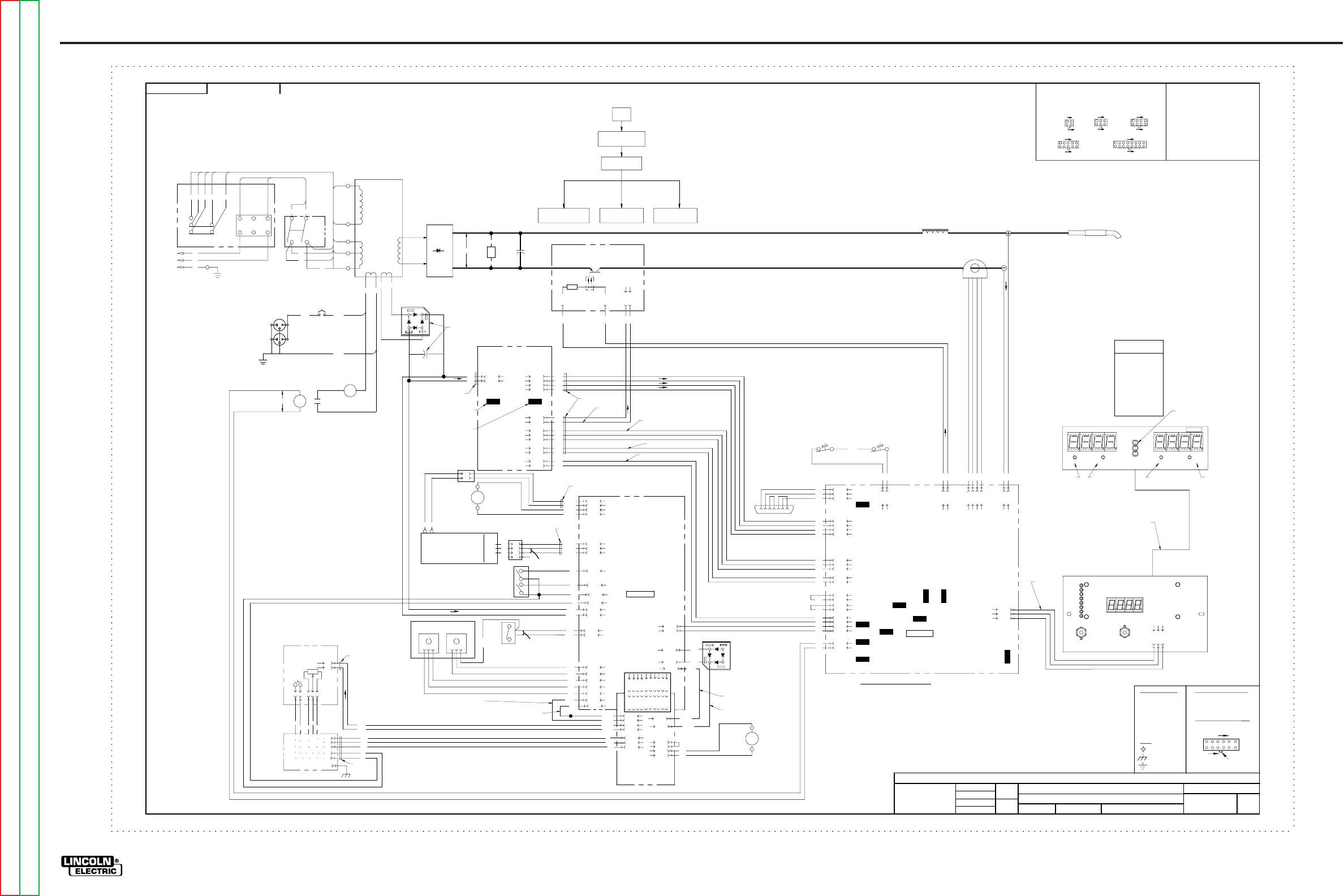

ELECTRICAL DIAGRAMS

G-3

POWER MIG 350MP

SCHEMATIC - ENTIRE MACHINE

EN-170

S

O

L

I

D

E

D

G

E

G4677

ENGINEERING CONTROLLED

MANUFACTURER:

No

CHANGE DETAIL: RELEASEDA.02 FROM X.

A

THE INFORMATION ON THIS

PRINT IS FOR REFERENCE

ONLY. COMPONENTS AND

CIRCUITRY MAY BE

DIFFERENT

FROM AN ACTUAL MACHINE.

G4677

POWER MIG 350MP

MACHINE SCHEMATIC

NONE

G4512

J. SKERBEC

JZUCKER

-

DRAWN BY:

DESIGN INFORMATION

ENGINEER:

APPROVED:

REFERENCE:

EQUIPMENT TYPE:

SUBJECT:

SCALE:

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

NA

CRM36729

1

PAGE ___ OF ___

1

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

12/10/2004

LEAD COLOR CODE:

B-BLACK

G-GREEN

O-ORANGE

R-RED

U-BLUE

W-WHITE

Y-YELLOW

COMPONENT VALUE UNITS:

CAPACITOR: MFD/VOLTS

RESISTOR: OHMS/WATTS

CONNECTOR PIN NUMBERS:

VIEW OF CONNECTOR ON PC BOARD

1

6

712

LATCH

EX. 12 PIN CONNECTOR

LABELS:

COMMON

FRAME GROUND

EARTH GROUND

J1,J86

CAVITY NUMBERING SEQUENCE

(COMPONENT SIDE OF P.C. BOARD)

J81,J82

6

5

10

1

3

4

1

2

J85,J87

9

8

16

1

4

6

1

3

J2,J84

5

4

8

1

J83,J88

GENERAL INFORMATION

ELECTRICAL SYMBOLS PER E1537

COLOR CODE

B -BLACK

W - WHITE

R -RED

U -BLUE

6J83

2J41

1J41

1J42

2J42

3J42

5J42

472 412

471 411

408

410

+15VDC CONTROL BD SUPPLY

-15VDC CONTROL BD SUPPLY

+5VDC CONTROL BD SUPPLY

CONTROL BD SUPPLY COMMON

DIGITAL POWER

SUPPLY P.C. BOARD

(SCHEMATIC G3631)

ILLUMINATED LED

INDICATES VOLTAGES ARE

BEING SUPPLIED TO J43

LED2

RED

LED1

RED

4J99

1J99

431

437

PWM = 20KHZ 12V

CHOPPER P.C. BOARD

(SCHEMATIC M19792-1)

LOCATED AT

MACHINE'S BASE

(WIRE DRIVE SIDE)

B8

B7

607

615

121K

G

EC

3J2

4J2

2

J8

4J8

1J8

6J8

253

802

254

804

801

806

+1

5

VD

C

L

E

M

S

UP

P

L

Y

L

EM

CO

M

M

O

N

- V

A

R

IA

B

LE

V

O

L

TA

G

E

F

EE

B

A

CK

CO

M

M

O

N

CONTROL

P.C. BOARD

(SCHEMATIC G3789)

LOCATED IN P.C. BOARD

COMPARTMENT

(LEFT FRONT SIDE)

VOLTAGE BETWEEN

801 AND 806 VARIES

DEPENDING ON

CURRENT THROUGH

LEM 500A = -4V

LED2

GREEN

LED1

LED7

RED

GREEN

LED3

GREEN

LED4

GREEN

LED6

GREEN

LED5

GREEN

LED8

G

R

E

E

N

REDLED'sARE SOLID AT

POWER UPTHEN BLANK

GREEN LED's REMAIN

SOLIDGREEN

4J6

10J6

604

15J7

16J7

715

716

1J11

2J11

1J2

251

3

J9

1J9

903

901

- STUD

+STUD

V

OL

T

A

GE

F

E

E

DB

A

C

K

15J6

7J6

615

607

P

W

M

CO

M

M

O

N

+P

W

M

S

I

GN

A

L

2J5

3J5

502

503

LE

D

1

0

R

E

D

L

E

D

9

G

R

E

E

N

REDLED'sARE SOLID AT

POWER UPTHEN BLANK

SWITCHES MUST BE

IN OFF POSITION

DIP SWITCHES

JUMPER ARE SO THE

CONTROL BOARD

RECOGNIZES

THAT IT IS IN A

PM300

THIS LED WILL BE

BLINKING IF THERE IS

AN ERROR

CAN COMMUNICATION

CAN COMMUNICATION

+ 15VDC

COM

+ 10VDC

COM

+ 10VDC

23 7

LOCATED ON TOP

OF P.C. BOARD

COMPARTMENT

FOR WELD FILE

DOWNLOADS

R232

CONNECTOR

1

2

3

4

503A

2J83

3J83

832:W

833

FEEDHEAD

P.C. BOARD

(SCHEMATIC G3883)

5J85

12J85

855

8512

8J85

11J85

4J83

834

SWITCHES MUST BE

IN OFF POSITION

DIP SWITCHES

MOTOR -

GAS SOLENOID +

GAS SOLENOID -

2J82

1J82

LOCATED IN LEFT SIDE OF

P.C. BOARD COMPARTMENT

10J85

9J85

7J85

858

8511

8510

859

857

312321

WFS/AMPS

VOLTS/TRIM

PANEL ENCODERS

8

55A

1J83

831:B

MOTOR +

1J85

2J85

851

852

7J84

4J84

847:U

844:B

1J84

841

5VDC TACH SUPPLY

TACH SIGNAL

TACH COM

GUN TRIGGER SUPPLY

GUN TRIGGER INPUT

+15VDC

COMMON

LOCATED TO THE RIGHT OF WIRE

DRIVE ASSEMBLY ONCENTER PANEL

LOCATED ABOVEWIRE

DRIVE ASSEMBLY ON

CENTER PANEL

LOCATED INSIDE THE

P.C. BOARD

COMPARTMENT

PLUGGED ONTO THE

FEED HEAD BOARD.

ACCESS THIS CONNECTOR

BY REMOVINGTHEWIRE

DRIVE ASSEMBLY

6 PIN FOOT AMPTROL

LOCATED IN P.C. BOARD

COMPARTMENT

SPOOL GUN/

PUSH-PULL

SWITCH

-

+

USED ONLY FOR

EXTERNAL DIODE

(USED FOR MOTOR

BRAKING)

RECTIFIER BRIDGE

5J83

836

835

15VDC WHEN IN THE SPOOL GUN

POSITION 0VDC WHEN IN THE

PUSH-PULL POSITION

1

2

3

4

R

U

B

R

U

B

LOCATED ON

CASEFRONT

TACH

2.6 VDC @ 50 IN/MIN

27.4 VDC @ 700 IN/MIN

8 SECOND AVERAGE CURRENT

LIMIT = 3.5A

(LIMIT IS SOFTWARE SET)

MEASURE B TO U (120 Hz @ 50 IN/MIN, 1.6 kHz@700 IN/MIN)

LOCATED ON

CASE BACK

PWM CONTROLLED

6.5 VDC WHEN GAS

FLOWING COIL

MEASURES 21 OHMS

12 VDC COIL

1

2

BW

SPI DISPLAY

L11757-1

YELLOW

REDRED

RED

RED

1 +15V

2 +5V

3/SS

4 CS1

5CS2

6CS3

7MISO

8 SCK

9MOSI

10GRD

FOR ALL FLEX AND

SHIELDED CABLE

SHIELDED

CABLE

4J11

3J11

CAN COMMUNICATION SUPPLY +5V

0V

1J43

431

7J43

437

3J43

403

6J43

402

12J43

401

4J43

406

9J43

405

5J43

1104

+5V

10J43

1103

COMMON

+5V

COMMON

+15V

COMMON

+5V

+20VDC

COMMON

12J4

11J4

412

411

8J4

408

+ 15VDC

-15VDC

+ 5VDC

1J3

2J3

10J3

+ 15VDC

+5VDC

+0VDC

3J4

2J4

403

402

1J4

401

+ 5VDC

SPI SUPPLY +15VDC

COM

6J4

5J4

406

405

10J4

410

RS232 SUPPLY + 5VDC

COM

COM

1104

1103

1101

1102

3J82

4J82

3233

3234

COMMON

TO POWER FEEDHEAD BOARD +42VDC

4

2

75

77

76

REMOTE

TRIGGER

REMOTE

TRIGGER

REMOTE

LOCATED AT BOTTOM OF

P.C. BOARD COMPARTMENT

SPOOL GUN

P.C. BOARD

(SCHEMATIC L12008-2)

D

F

E

A

C

B

2A

4A

77A

76A

75A

ALL LED's

LIGHT

BRIEFLY

A DASH "-" SCROLLS

ALONG DISPLAY BOARD

(TAKES ABOUT 10 SECONDS)

MACHINE DISPLAYS

SETTINGS OF LAST

WELD MODE OPERATION

AMP LED ILLUMINATES

WITH CORRESPONDING VALUE.

RIGHT DISPLAY "OFF"

WFS AND VOLTAGE

LED's ILLUMINATE WITH

CORRESPONDING VALUES.

WFS AND TRIM

LED's ILLUMINATE WITH

CORRESPONDING VALUES.

IF LAST MODE WAS CC IF LAST MODE WAS CV IF LAST MODE WAS SYNERGIC

3214

3218

F

ECDG

A

B

MOTOR +

MOTOR -

5K

S

POOL GUN/PUSH-PULL MOTOR

0VDC @ 50 IN/MIN

24VDC@700 IN/MIN

7 PIN AMPTROL

SPOOL/PUSH-PULL GUN

CURRENT

TRANSDUCER

OUTPUT

CHOKE

5

0

w

a

t

t

s

5

0

0

o

h

m

s

2520

2530

R1

+

2400/100

+

-

57 VAC

-

+

DIODE RECTIFIER

80 VDC

INPUT

RECTIFIER

MAIN

TRANSFORMER

+

6800/75

X6X5

X4X3

PWM: PULSE WIDTH

MODULATION

CHOPPER

SUPPLY

30 VAC115 VAC

LOCATED ON TOP OF

MAIN TRANSFORMER

SCHEMATIC: L11108

MSP3 BOARD

(SCHEMATIC: L11612)

LOCATED ON

SECONDARY

WINDINGS

LOCATED ON

CHOPPER BOARD

HEATSINK

FAN STAYS ON FOR 5 MIN AFTER

LAST GUN TRIGGER (WHEN 2/4

ISCLOSED)

CR1

FAN

FAN RELAY

11J6

12J6

611

45 206

TOROID

TOROID

TOROID

TOROID

LOCATED ON

DIVIDER

PANEL IN THE

WIRE DRIVE

COMPARTMENT

TOROID

LOCATED ON

TRANSFORMER

BAFFLE

LOCATED ON

TRANSFORMER

BAFFLE

TOROID

+ 42VDC

LOCATED ON FRONT

OF MACHINE'S BASE

LOCATED ON

MACHINE'S BASE

(STORAGE

COMPARTMENT SIDE)

H1

H4

H1

(SHOWN

CONNECTED

FOR 230V)

H4

H3

H2H5

L2

L1

G

B

W

H1

L1

L2

H4

H1

H4

H3

H5

H2

H1

LINE

SWITCH

RECONNECT PANEL

LOCATED ON

DIVIDER

PANEL IN THE

WIRE DRIVE

COMPARTMENT

LOCATED NEXT TO

MAIN TRANSFORMER

(ON WIRE DRIVE SIDE)

LOCATED ON

CHOPPER BOARD

ASSEMBLY

CONTROL P.C. BOARD LED LEGEND

LED1: +15VPOWER TO CONTROL P.C. BOARD

LED2: -

15V POWER TO CONTROL P.C. BOARD

LED3: +5V FOR SPI CABLE

LED4: +15V FOR SPI CABLE

LED5: +

5V POWER TO CONTROL P.C. BOARD

LED6: +5V FOR RS232 CONNECTOR

LED7: A FATAL ERROR HAS OCCURED

LED8: +5V FOR CANCOMMUNICATION

LED9 AND LED10: ERROR CODE. LED9 BLINKSONCE

THEN LED10 BLINKSERRORCODE.

15 V

N.C.

N.C.

ALL 3 LED'S ILLUMINATE

AT THERMAL TRIP.

SELECT

SWITCH

SET

SWITCH

ILLUMINATED LED

INDICATES VOLTAGES ARE

BEING SUPPLIED TO J42

ILLUMINATES WHEN

DISPLAYING WFS

ILLUMINATES WHEN

DISPLAYING AMPS

ILLUMINATES WHEN

DISPLAYING VOLTS

ILLUMINATES WHEN

DISPLAYING TRIM

PROVIDES BRAKING OFTHE

SPOOL/PUSH-PULL GUN

MOTOR ANDCONDITIONS

THE SIGNAL FROM THE

POTENTIOMETER.

CONTROLS THE WIRE

DRIVE FUNCTIONS AND

THE GAS SOLENOID.

CONTROLS THE

FUNCTIONALITY OF

THE MACHINE.

ALLOWS THE SELECTION OF DIFFERENT WELD

MODES ANDPROCESSES.

1

J34

2J34

10J34

S

PI FLEX/SHIELDED

CABLE SUPPLY

RS232 SUPPLY

CAN COMMUNICATION

SUPPLY

2

J86

7J86

1J86

3J86

6J86

4J86

8J86

6J86

9J86

10J86

2P86

7P86

1P86

3P86

6P86

4P86

8P86

6P86

9P86

10P86

14J85

8514

3J810

2J810

1J810

5J810

6J810

4J810

8J810

77

3218

3214

8514

76

846A

75

6J84

846

4J85

3J85

2B

853

DUAL PROCEDURE SUPPLY

DUAL PROCEDURE INPUT

1

2

3

4

851A

4

2

2J811

1J811

8115

8111

5J88

8115

FLEX

TO SPOOL/PUSH-PULL

GUN MOTOR DRIVE

+40V DC SUPPLY FOR

SPOOL/PUSH-PULL GUN MOTOR

0-5V SIGNAL VARIES WITH

REMOTE POT WIPER

SPOOL/PUSH-PULL GUN

BRAKE SIGNAL

(0 VOLT= MOTOR BRAKE)

CIRCUIT

BREAKER

15A

1205

115V

LOCATED ON

CASE BACK

1203

1204

MOTOR / GEARBOX

STANDARD MAGNUM

SPOOL GUN

2J812

3J812

8123

4J812

8124

GAS SOLENOID+

GAS SOLENOID -

1J812

LOCATED ON

CASE BACK

PWM CONTROLLED

6.5 VDC WHEN GAS

FLOWING COIL

MEASURES 21 OHMS

12 VDC COIL

SPOOL GUN/TIG

SOLENOID

G-3

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.