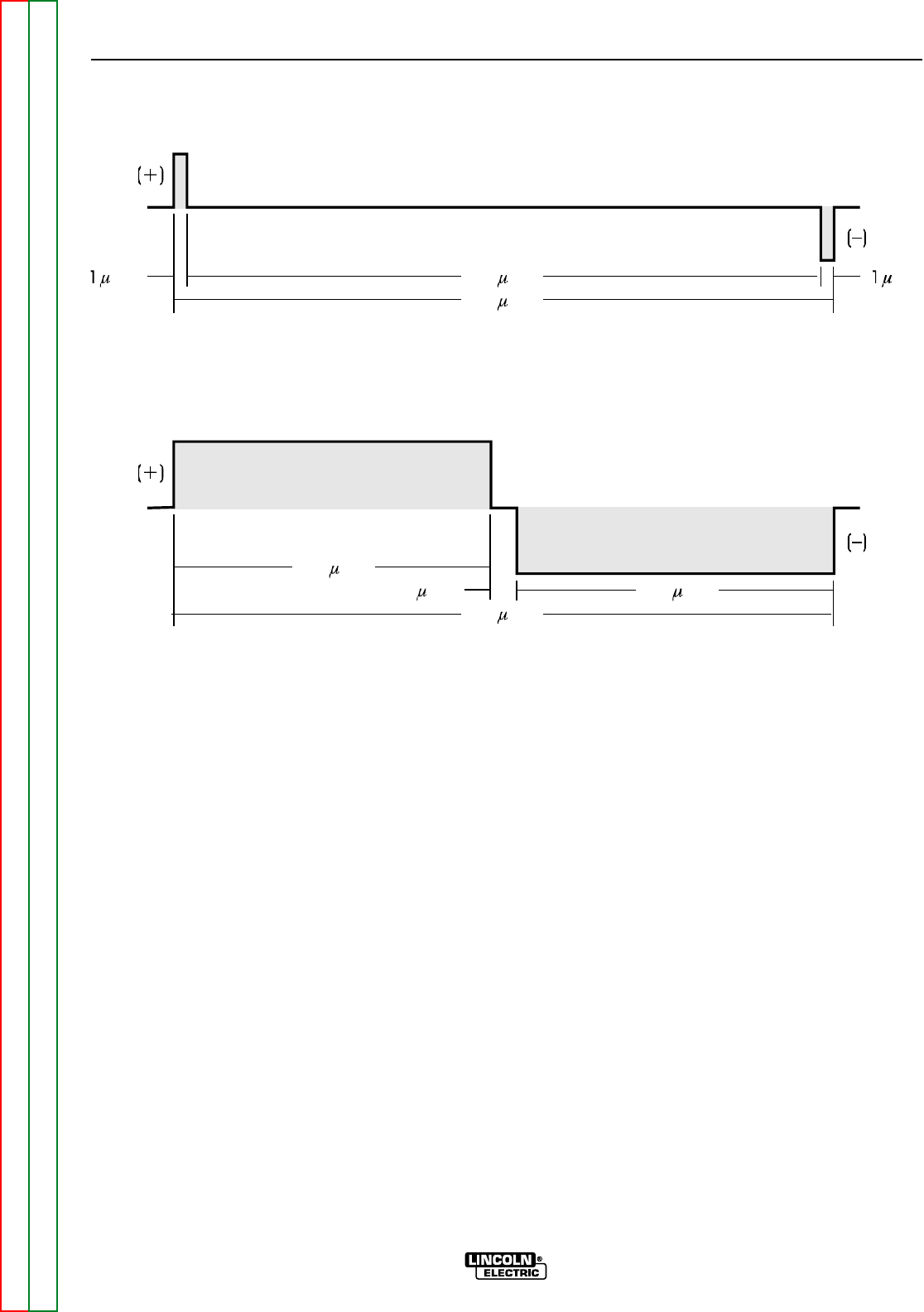

PULSE WIDTH MODULATION

The term PULSE WIDTH MODULATION is used to

describe how much time is devoted to conduction in

the positive and negative portions of the cycle.

Changing the pulse width is known as MODULATION.

Pulse Width Modulation (PWM) is the varying of the

pulse width over the allowed range of a cycle to affect

the output of the machine.

MINIMUM OUTPUT

By controlling the duration of the gate signal, the IGBT

is turned on and off for different durations during a

cycle. The top drawing above shows the minimum out-

put signal possible over a 50-microsecond time period.

The positive portion of the signal represents one

IGBT group conducting for 1 microsecond. The nega-

tive portion is the other IGBT group. The dwell time

(off time) is 48 microseconds (both IGBT groups off).

Since only 2 microseconds of the 50-microsecond time

period is devoted to conducting, the output power is

minimized.

MAXIMUM OUTPUT

By holding the gate signals on for 48 microseconds

each and allowing only 2 microseconds of dwell time

(off time) during the 50-microsecond cycle, the output is

maximized. The darkened area under the top curve

can be compared to the area under the bottom curve.

The more dark area under the curve, the more power is

present.

THEORY OF OPERATION

E-10 E-10

POWER MIG 350MP

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FIGURE E.9 – TYPICAL IGBT OUTPUTS

MINIMUM OUTPUT

MAXIMUM OUTPUT

24

50

24

2

48

50

sec

sec

sec

sec

sec

sec

sec

sec