11

Depth of Cut

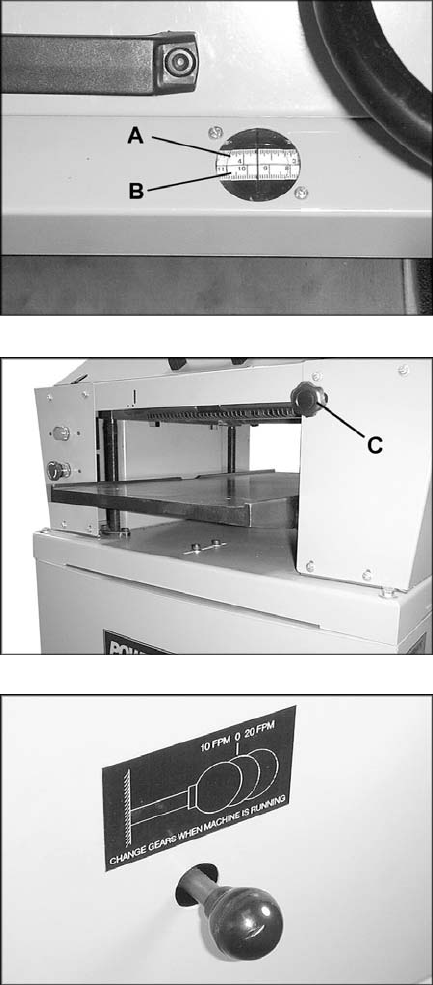

The depth of cut scale, shown in Figure 9 , has

been calibrated at the factory. However, it

should be checked periodically to maintain

accuracy:

1. Disconnect machine from power source.

2. Lift the hood and rotate the cutterhead by

hand until one of the planer knives is at the

bottom of its rotation nearest the planer bed.

Hand crank the planer bed down and place

a piece of stock underneath both feed

rollers and the cutterhead. Measure the

thickness of the piece of stock.

3. Hand crank the planer bed up until the knife

at the bottom of the rotation has just

touched the top of the stock lying on the

planer bed. Compare the measured

thickness of the board to the reading on the

depth of cut scale.

4. If the reading on the depth of cut scale is

incorrect, loosen the two mounting screws

on the clear plastic plate and adjust

accordingly. The top scale (A, Fig. 9) is in

English units, the bottom scale (B, Fig. 10)

is metric.

5. Test the adjustment by planing a piece of

scrap lumber, and make further adjustments

as necessary.

NOTE: The table lock (C, Fig. 10) must be

tightened before operating the planer/molder.

Feed Rate

The feed rate is set by the adjustment lever on

the side of the machine. See Figure 11. Always

change feed rate WHILE THE MACHINE IS

RUNNING.

The Planer’s Feed System

(Figure 12)

1. Anti-kickback fingers

2. Infeed roller

3. Chipbreaker

4. Cutterhead

5. Outfeed roller

Anti-Kickback Fingers

Anti-kickback fingers help prevent stock from

being thrown from the machine. These fingers

operate by gravity and should be inspected

before each day's use for pitch or gum buildup.

The fingers must operate freely and move

independently for correct operation.

Figure 9

Figure 10

Figure 11