18

Homemade Bedboard

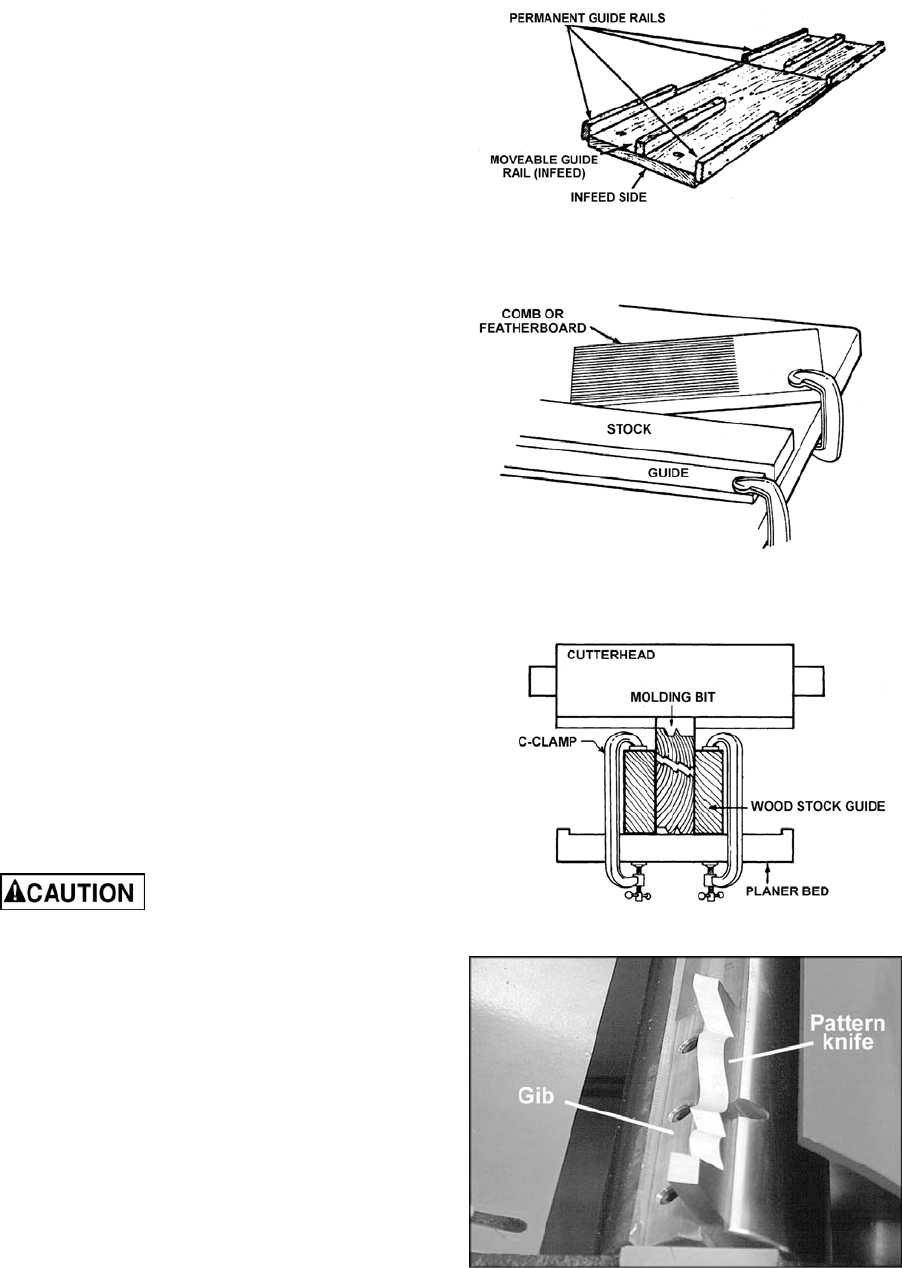

A homemade bedboard can be made as shown

in Figure 26. Permanent guide rails are mounted

as shown.

Homemade Featherboard

For face molding, a homemade guide and comb

or featherboard can be combined to position

stock for desired pattern cuts. See Figure 27.

Select a straight piece of hardwood for the

guide. This piece should be 2” x 1/2” and at

least 27-1/4” long. The guide should be exactly

parallel to the milled edge of the planer bed. The

guide can be held in place with C-clamps. You

will have to cut clearances in the guide so the

guide will fit beneath the rollers.

A featherboard can be of great help in guiding

stock. It is quickly made from any piece of 1”

thick stock, approximately 8” long and 3” wide.

Saw the parallel slots about 4” deep and 1/8”

apart. The feather board can be C-clamped at

any position to exert a spring tension to hold the

stock against the guide.

Homemade Guide Set-Up for Edge

Molding

Figure 28 shows a wooden guide set-up for

edge molding. The guides are C-clamped on

each side of the stock and are within 3/4” of the

top edge to provide maximum support so that

the narrow stock will travel beneath the knife.

Installing Single Pattern Knives

Pattern knives are easy to install and adjust.

Always disconnect machine

from power source before changing knives

or molding bits. Always use the gib(s)

supplied with a particular molding knife.

1. Loosen the gib set screws and tap all gibs

down to release the planer knives.

2. Remove the planer knives, then the gibs

and jack screws. Clean the cutterhead slots

and the custom pattern knife thoroughly with

a nonflammable solvent to remove all wood,

dust, gum, and any protective coatings.

3. Re-install the jack screws. Install the

aluminum gib and then the pattern knife into

one of the cutterhead slots. See Figure 29.

Tighten the gib set screws. Double check

during this tightening, to insure against the

knife creeping up during the tightening

process. If necessary, tap the knife down

with a hard wood block until it has bottomed

out in the cutterhead slot.

Figure 26

Figure 27

Figure 28

Figure 29