13

tensionin

g

ad

j

ustment, and to set the roller

back to the original height.

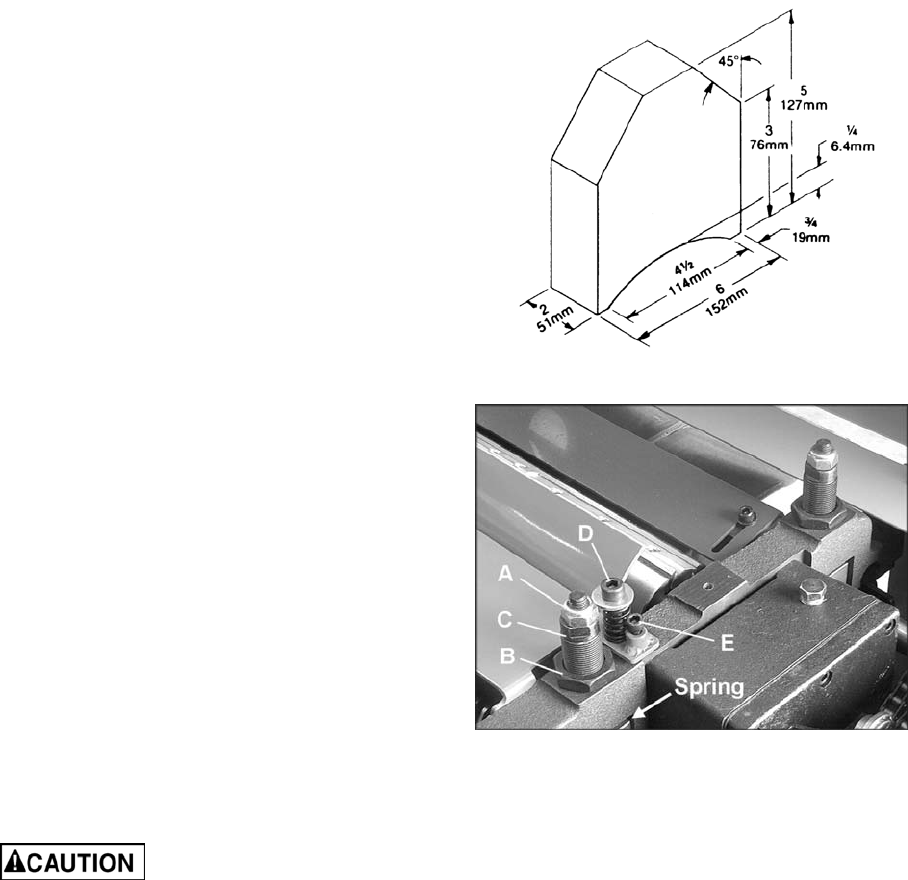

3. The spring which is located above the

bushing block (see Figure 15) must not

be compressed too tightly, as this will

restrict movement of the infeed roller and

may cause machine damage due to flexing

of the roller. Lift up the infeed roller with

your hand – there should still be sufficient

travel in the infeed roller.

4. If necessary, continue to adjust tension and

height in combination with one another,

while being careful to prevent excess spring

compression.

5. Repeat for the other end of the infeed roller.

The tension should be equal at both ends of

the roller.

Chipbreaker

The functions of the chipbreaker are to break

chips into small pieces, help avoid splintering of

the wood, help avoid board bounce on thinner

boards, and to direct the flow of chips out of the

machine.

The chipbreaker is factory adjusted to be 1/32”

below the cutting arc of the knives. Tension is

adjusted by the screw and spring (D, Fig. 15).

The height is adjusted with the socket head

screw (E, Fig. 15).

Some molding applications may require the

spring tension to be relieved to avoid scraping

the profile of a part.

A chipbreaker set too low

may prevent stock from feeding into the

machine.

NOTE: If the infeed roller setting is altered, the

chipbreaker tension may need to be readjusted

as well.

Outfeed Roller

The outfeed roller should exert enough pressure

to pull the board through the cutterhead after it

leaves the infeed roller. The correct position of

the outfeed roller is 1/32” below the arc of the

cutterhead knives. If the board halts or bumps

when it first contacts the outfeed roller, tension

should be reduced. If the board stops or does

not continue feeding smoothly after starting

under the outfeed roller, then tension should be

increased. As with the infeed roller, height and

tension of the outfeed roller should be set in

combination with each other.

Figure 14

Figure 15