23

Maintenance

Build-up of sawdust and other debris can cause

your machine to plane and mold inaccurately.

Periodic cleaning and waxing is not only

recommended, but necessary for accurate work.

Always disconnect machine

from power source before performing

maintenance.

1. Close fitting parts, such as gibs and the

planer cutterhead slots should be wiped with

a cloth and non-flammable solvent and

freed from clinging foreign matter and then

replaced in respective position, slightly

dampened with oil. Do not soak these parts

in oil.

2. Occasional use of paste wax on the bed will

prevent rust and reduce friction to ease

feeding.

NOTE: Using too much paste wax will allow

the wax to rub off onto the planed wood and

contaminate the wood surface affecting

subsequent finishing.

3. Remove resin and other accumulations from

feed rollers and bed with a non-flammable

solvent

4. Periodically check all the chains for proper

tension and adjust accordingly if required.

Lubrication

1. The recommended lubrication for roller

chains used in medium to slow speed

operation is to simply wipe the chain clean.

When there is an appreciable build up of

dust, dirt or wood shavings, use an oil cloth

but never pour the oil directly on the chain.

Over-oiling defeats the purpose of the

lubrication, since it tends to invite the

collecting of dust, shavings, etc. and works

into members of the chain. This hastens

wear and leads to premature replacement.

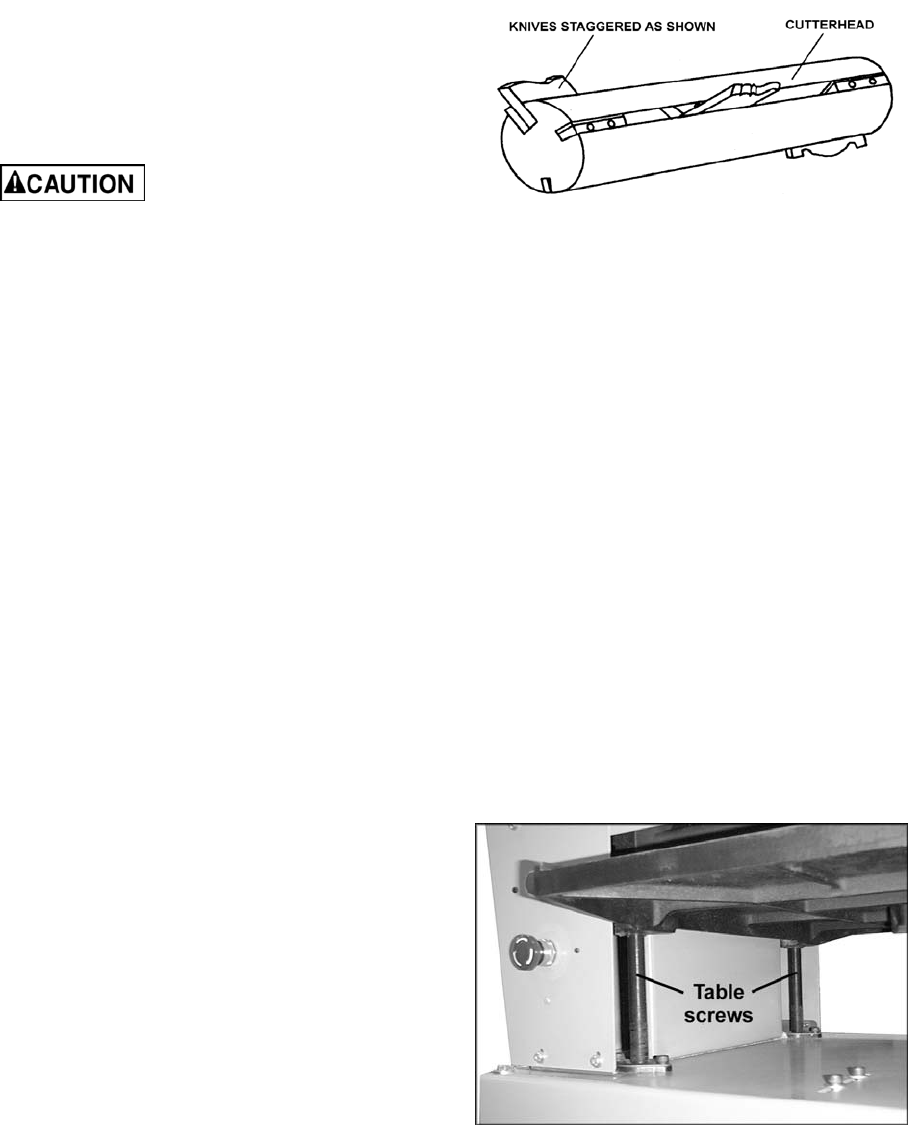

2. The bearings on the cutterhead are factory

lubricated and sealed. They require no

further attention.

3. When using the planer/molder in a high

humidity area, the four corner screws,

shown in Figure 42, should be coated with

grease or a rust-preventative.

4. The oil in the gearbox should be drained

and replaced about every 2,500 hours of

use. Multi-purpose 70 to 90 weight gearbox

oil is suitable.

Figure 41

Figure 42