15

Interlock Switch

This machine has an interlocking safety switch

located under the hood. The hood must be in

the “down” position in order for the planer motor

to engage.

If the hood is lifted while the machine is

operating, the motor will cut off. The interlock

switch must be adjusted so that it will turn off the

motor if the hood is raised more than 11/16”.

Do not operate the planer

unless the interlock switch is working

properly.

Caster Lock

The casters should be locked before operating

the planer-molder. The foot pedal on the right

side of the machine can be pressed down to

lock the casters as shown in Figure 19.

Operation

Kinds of Warp

Warp is a variation from a plane or true surface.

Warping of wood is caused by uneven

shrinkage during the drying process. Shrinkage

is not the same in all directions of the grain and

due to the different grain direction in pieces of

lumber, different types of warpage can occur.

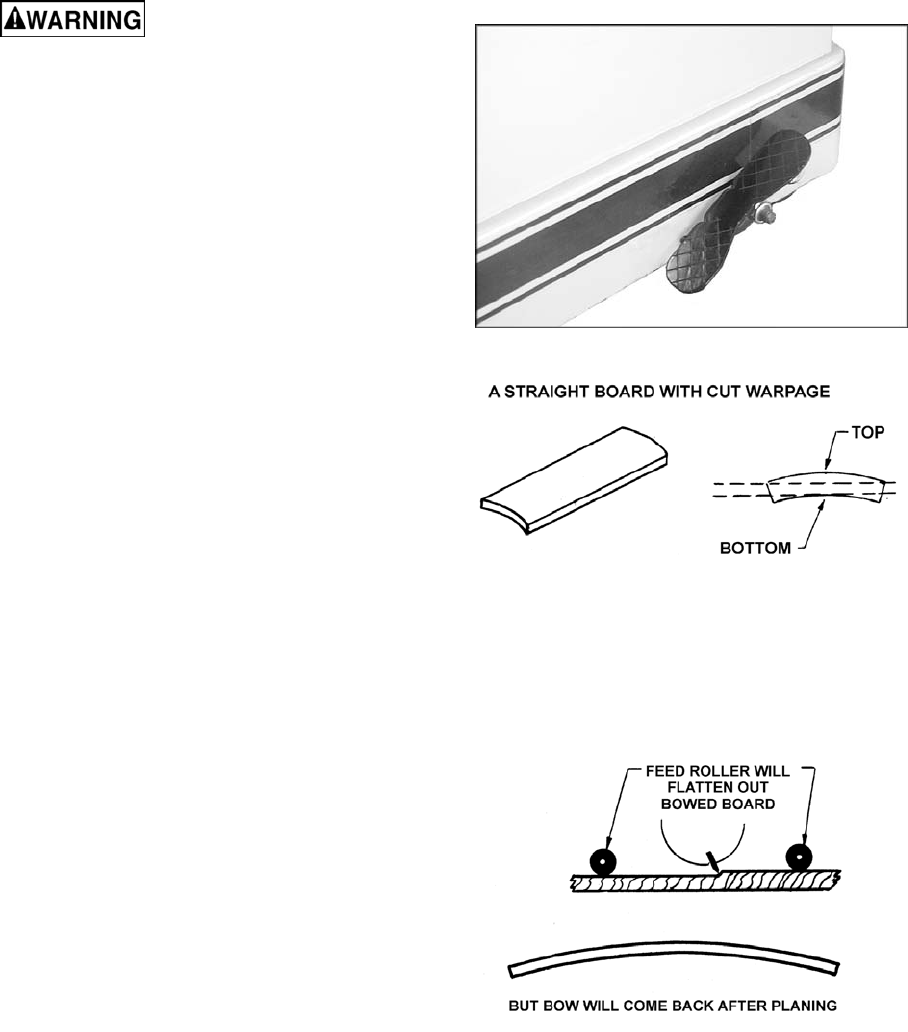

Cup or warped across width

With a board that is cupped you would first

plane the top flat and then turn the board over

and plane the bottom flat. See Figure 20. If

possible, ripping the board down the middle of

the cup would eliminate a large amount of waste

in planing to thickness.

Bow or warped lengthwise

The feed rollers on a thickness planer are going

to flatten a bowed board down against the

planer bed and thickness plane the board as if it

had little or no warpage. Then after the board is

removed from the planer it will be planed to

thickness but still have its original bow. See

Figure 21. The only way to remove the bow from

a board is to joint the board flat on one side on a

jointer. Then the board can be thickness planed.

Twist or twisted lengthwise

Twisted lumber is the most difficult warpage to

plane to thickness. In some cases the twisting is

so great that planing to thickness is impossible.

In this case you might saw the board into

smaller pieces and see if planing to thickness

can be achieved.

Figure 19

Figure 20

Figure 21