16

Planing to Desired Thickness

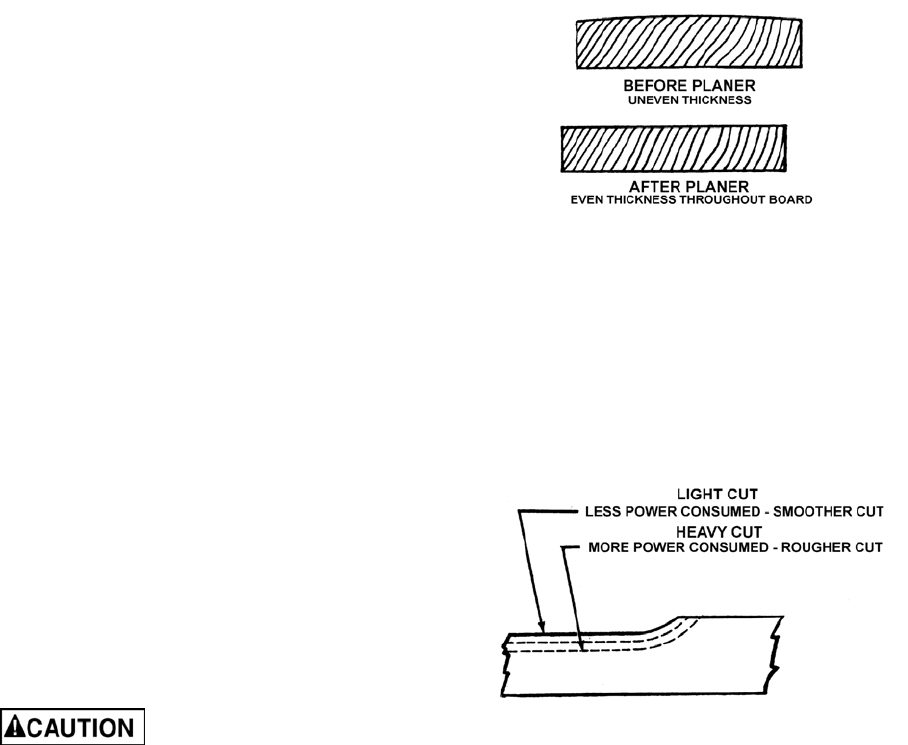

Thickness planing is the sizing of material to a

desired thickness, while creating a smooth

surface parallel to the opposite side of the

board. See Figure 22.

The art of thickness planing consists mainly of

using good judgment about the depth of cut in

various situations. You must take into account

not only the width of the stock, but the hardness

of the board, its dampness, straightness, grain

direction, and grain structure.

The effects of these factors upon the quality of

the finished work can only be learned through

experience. It is always advisable, whenever

working with a new type board, or one with

unusual problems, to make test cuts on scrap

material if possible prior to working on your

finished product.

Depth of Cut

The thickness of stock run through the planer is

controlled by the distance you adjust the bed

from the cutting knife. Always start your work by

making a light planing cut. The depth of cut on

subsequent passes may be increased, up to

1/8”, however, remember that a light cut creates

a finer finish than a heavier cut. See Figure 23.

Never plane more than 1/8”

in one pass and never attempt to plane a

board under 8” in length.

Thickness Planing Steps

To properly use your planer/molder for thickness

planing, follow these steps:

1. Measure the thickest part of the board to be

planed. Turn the elevation control handle

until the scale depth of cut reads the

thickness of the board to be planed. Each

revolution of the handle raises the bed 1/16”

(1.5mm)

2. If desired thickness is greater than 3/16”,

make several passes.

NOTE: It is recommended that a board be

planed on both sides to the desired thickness.

Then the moisture content will be uniform and

the drying process will not warp the board. For

example, if 3/16” thickness is desired, remove

3/32” from each side.

Figure 22

Figure 23