20

A

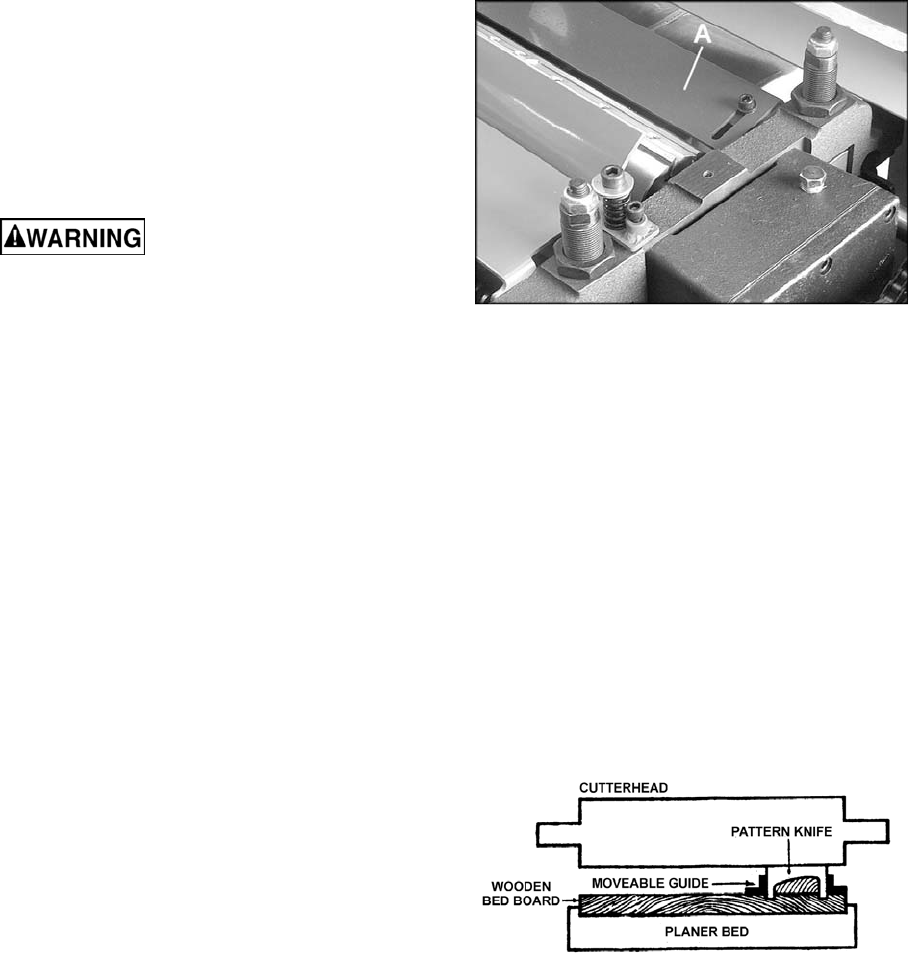

lso the rear chip deflector

(

A, Fi

g

. 33

)

must be

set properly. There must be no contact between

the pattern knife and the chip deflector. Rotate

the cutterhead by hand to make sure there is

clearance. This is especially important when the

operator has inserted a pattern knife and left the

planer blades in the cutterhead. The chip

deflector must be moved to clear the pattern

knife.

Double check all gib screws

for tightness before operating the machine. If

the chipbreaker is damaged or worn it must

be replaced.

Installing Bedboard

The knives are made so the extreme cutting tips

can cut into the wood bedboard by

approximately 1/16”. This is necessary to

eliminate rough edges and for final sizing.

Always use a bed board so the knife does not

come into contact with the cast iron bed of the

planer.

Once the bedboard is securely mounted, the

guides must be adjusted so they are in line with

the pattern knife. Proper adjustment of the

guides will insure quality cut moldings.

1. To adjust the guides, lower the bed and

place a board of correct width to be molded

under the cutterhead.

2. Loosely adjust the guides to the board.

Rotate the cutterhead by hand and see if

the pattern knife will line up with the board.

Adjust accordingly until the pattern knife and

board are lined up as in Figure 34.

3. When properly adjusted, firmly tighten the

bed guides.

NOTE: On some pattern knives the cutter trims

a small portion of the width away as it cuts the

pattern. The outfeed guides on the bedboard

must be adjusted to compensate for the

decreased width of the molding.

Face Molding with pattern knives

The art of creating quality molding requires

planning your molding operations prior to

starting. The depth of cut can dictate the

smoothness of the finish. Remember, a light cut

creates a finer finish than a heavier cut.

Always pre-size your stock to within 1/16” of the

final thickness before running your molding. If

possible, pre-size it to within 1/8” in width also

as shown in Figure 35.

Figure 33

Figure 34