17

3. Stand to one side of the machine and start

the board under the infeed roller so that it

travels in a straight line. As the infeed roller

takes hold, let go and remain standing to

one side of the unit – never directly in line

with the board. The power feed will

complete the travel without further pushing

or pulling.

Planing for Finish

Planing for a smooth finish is best accomplished

by taking light cuts on the board. However,

several other things are important to achieve a

smooth finish.

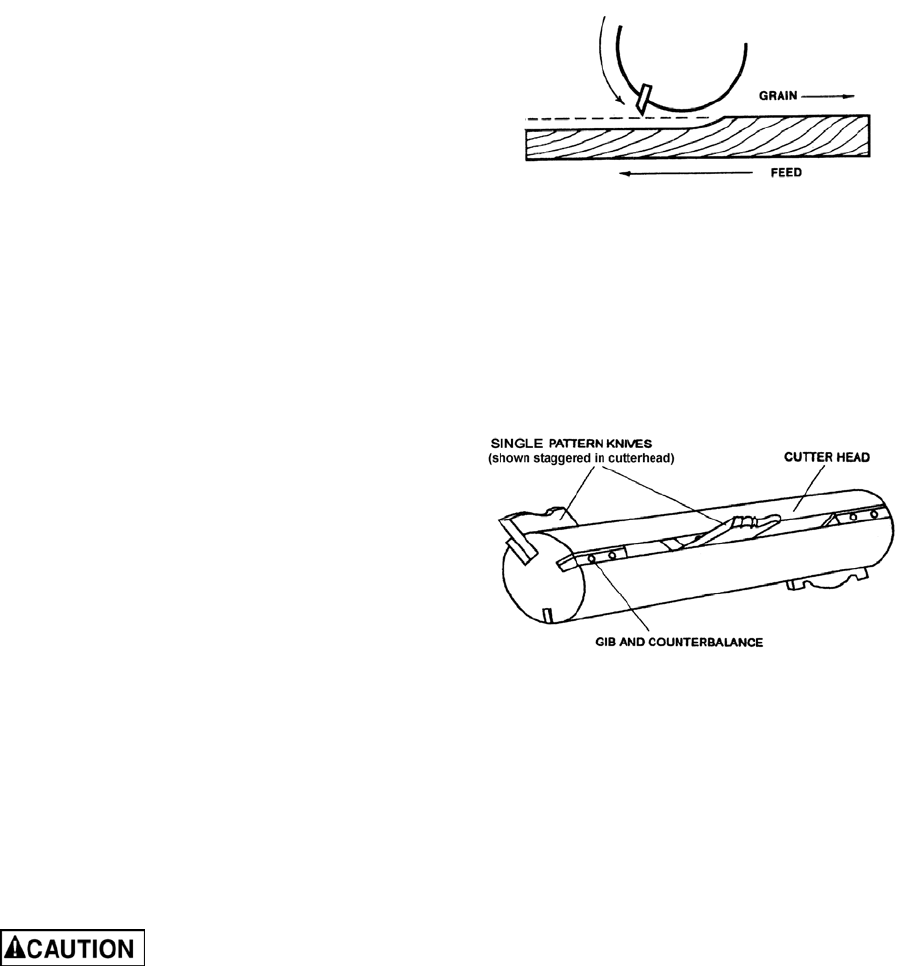

Always feed board in a direction that allows the

planer blades to cut with the grain as shown in

Figure 24. This aids the knife in severing the

wood fibers rather than lifting and tearing the

fibers. Torn fibers give a fuzzy appearance to

the surface. Feeding against the grain can also

cause your knife to lift large chips from the

board’s surface, causing a very unsightly

appearance.

Introduction to Molding

Pattern Knives

Custom molding knives are ground from high

speed hard steel. Your PM15 planer-molder will

accept a single knife set, which uses gibs and

counterbalances to ensure the cutterhead is in

balance at all times. See Figure 25. It will also

accept a three-knife set.

The three-knife molding set allows the planing

knives to remain within the cutterhead, as long

as the pattern knife is no more than 1/8” thick

and no wider than 3”.

Optional Bedboard and Guide

The use of a bedboard is highly recommended

and can be extremely critical in cases such as

custom pattern knives and molding bits where

they are designed to cut below the molding to

eliminate rough edges and to final size the

molding. In this case, the use of a bedboard is

mandatory in keeping the tips of the custom

pattern knives away from the cast planer bed.

Always use a bedboard with

a custom pattern knife, or damage to the

knives, planer bed and cutterhead can result.

Figure 24

Figure 25