9

Extension Cords

If an extension cord is necessary, make sure the

cord rating is suitable for the amperage listed on

the machine’s motor plate. An under sized cord

will cause a drop in line voltage resulting in loss

of power and overheating.

Use the chart in Figure 4 as a general guide in

choosing the correct size cord. If in doubt, use

the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Adjustments

Tools required:

hex wrench

12mm & 14mm wrenches

Disconnect machine from

power source before making adjustments.

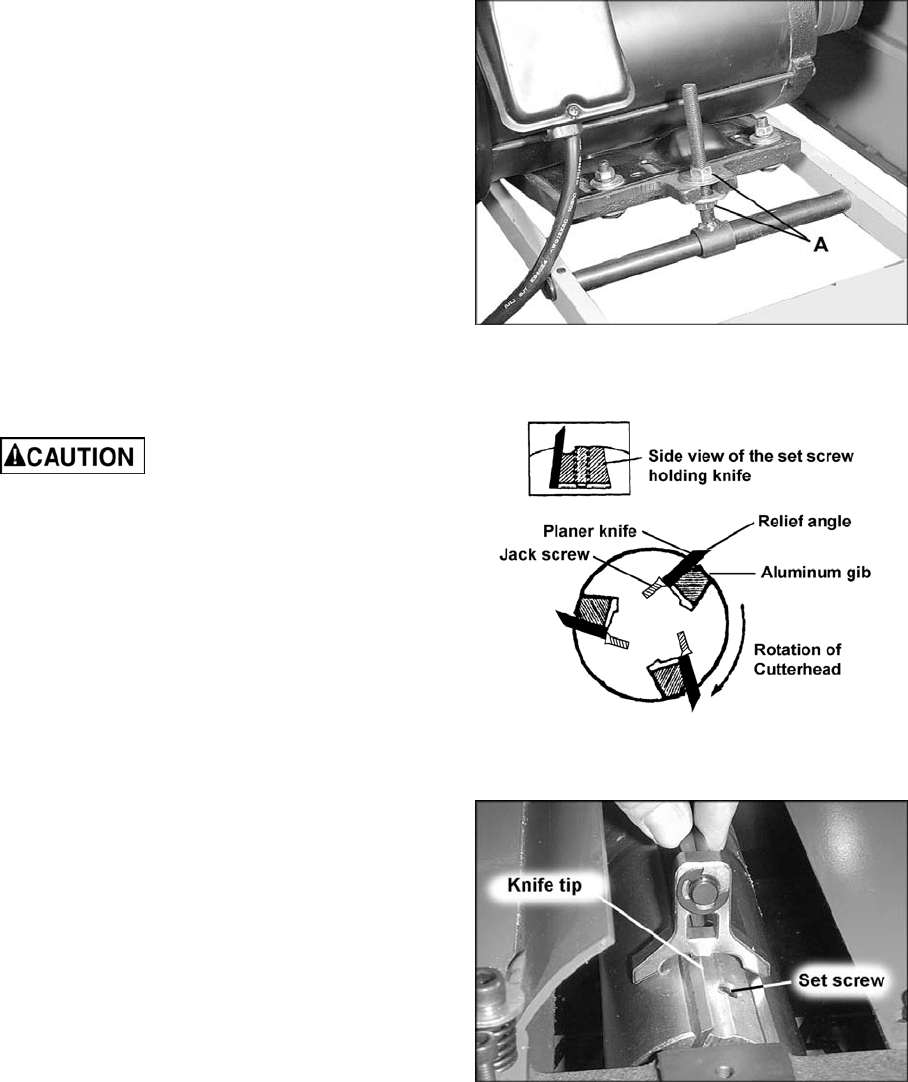

Belt Tension

To adjust tension of the belts, open the rear

panel and use the nuts (A) on the threaded

shaft, shown in Figure 4, to either raise or lower

the motor. Re-tighten nuts when satisfied.

Proper tension is achieved when there is

approximately 1/4” deflection in the belt using

moderate finger pressure.

Planer Knife Replacement

1. The planer knives are held in position by

wedge action. The set screws press against

the bottom of the cutterhead slot forcing the

gibs into a wedge type seal. To break this

seal and remove the knife, simply loosen

the gib set screws until they are flush with

the top of the gibs. See Figure 6.

2. Tap the gibs down using either a wood

block or a soft piece of aluminum or brass (a

brass punch is provided with your machine).

Once the gibs are free, remove the knife

first, then the gibs can be easily removed.

Mark all gibs and matching slots to be sure

they are replaced in their original position.

3. Clean the knives and cutterhead slot with a

non-flammable solvent to remove all pitch

and gum residue.

4. Install the gibs back into their original slots,

then install the planer knives.

5. Place the knife-setting gauge on the

cutterhead, centered over the knife. See

Figure 7. Check the height of the knife at

several locations along the length of the

knife. At all points, it should just contact the

center of the gauge.

Figure 5

Figure 6

Figure 7