Alignment and Adjustment

Blade alignment and adjustment are com-

plet_ Note:/t is important that you peri-

odically check alignment and adjustment to

insure accurate cuts and improve the safety

of cutting procedures. Be aware that align-

ment in one plane necessarily affects align-

ment in other planes. Thus, the blade may

be perfectly aligned for one tape of cut but

not another.

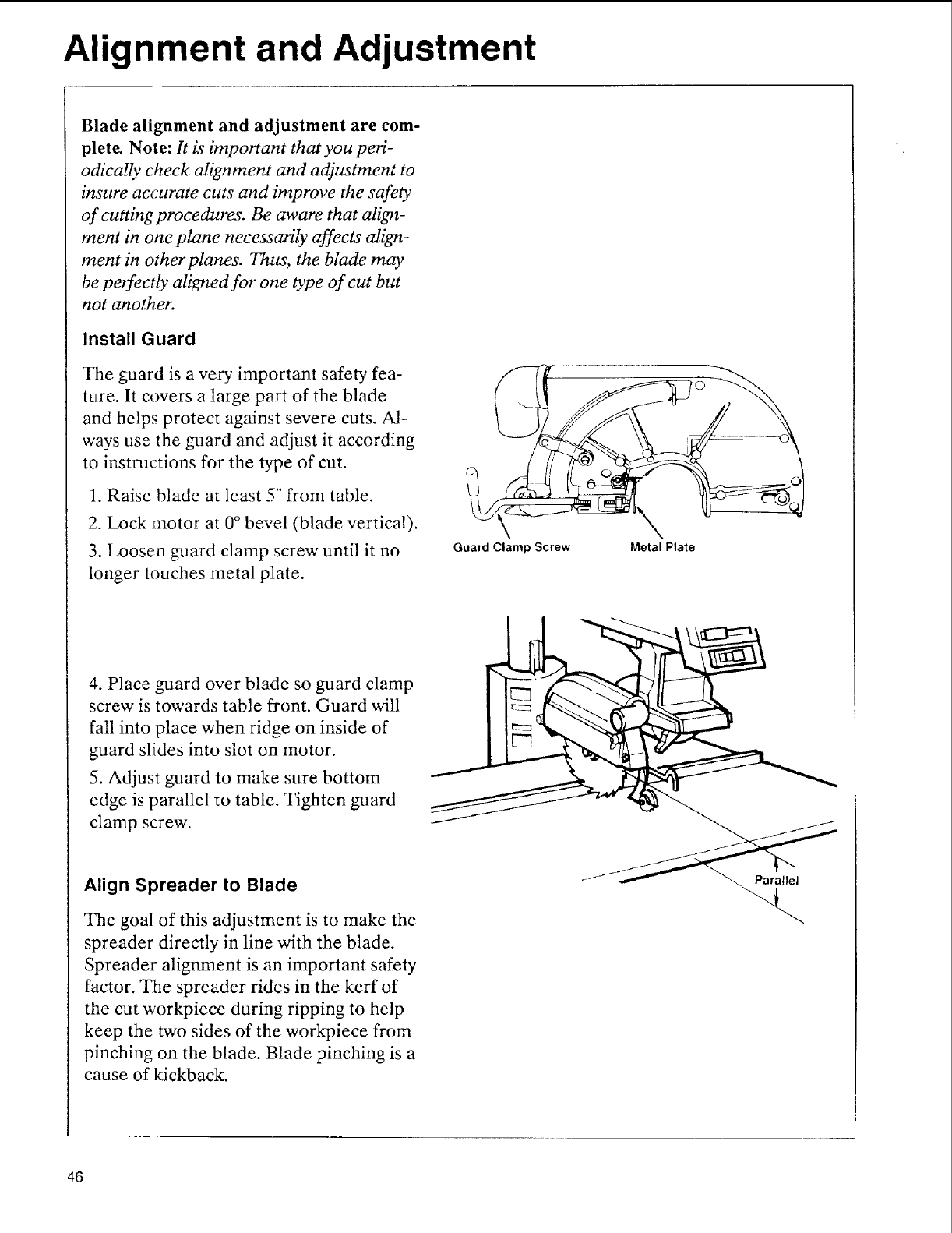

Install Guard

The guard is a very important safety fea-

ture. It covers a large part of the blade

and helps protect against severe cuts. Al-

ways use the guard and adjust it according

to instructions for the type of cut.

1. Raise blade at least 5" from table.

2. Lock motor at 0° bevel (blade vertical).

3. Loosen guard clamp screw until it no

longer touches metal plate.

Guard Clamp Screw

!©

Metal Plate

4. Place guard over blade so guard clamp

screw is towards table front. Guard will

fall into place when ridge on inside of

guard slides into slot on motor.

5. Adjust guard to make sure bottom

edge is parallel to table. Tighten guard

clamp screw.

Align Spreader to Blade

The goal of this adjustment is to make the

spreader directly in line with the blade.

Spreader alignment is an important safety

factor. The spreader rides in the kerf of

the cut workpiece during ripping to help

keep the two sides of the workpiece from

pinching on the blade. Blade pinching is a

cause of kickback.

_. Parallel

46