For Machines Mfg. Since 3/11 16-Speed Gearhead Lathe

-73-

MAINTENANCE

To change the coolant:

1. Position the coolant nozzle over the splash

guard so that it is pointing behind the lathe.

If you have the optional hose, connect it to

the end of the nozzle now.

2. Place the 5-gallon bucket behind the lathe

and under the coolant nozzle. If you have the

optional hose, place the hose in the bucket.

Otherwise, you may need to have an another

person hold the bucket up to the nozzle to

prevent coolant from splashing out of the

bucket.

3. Turn the coolant pump ON and pump the

old fluid out of the reservoir. Turn the pump

OFF immediately after the fluid stops

flowing.

Adding Fluid

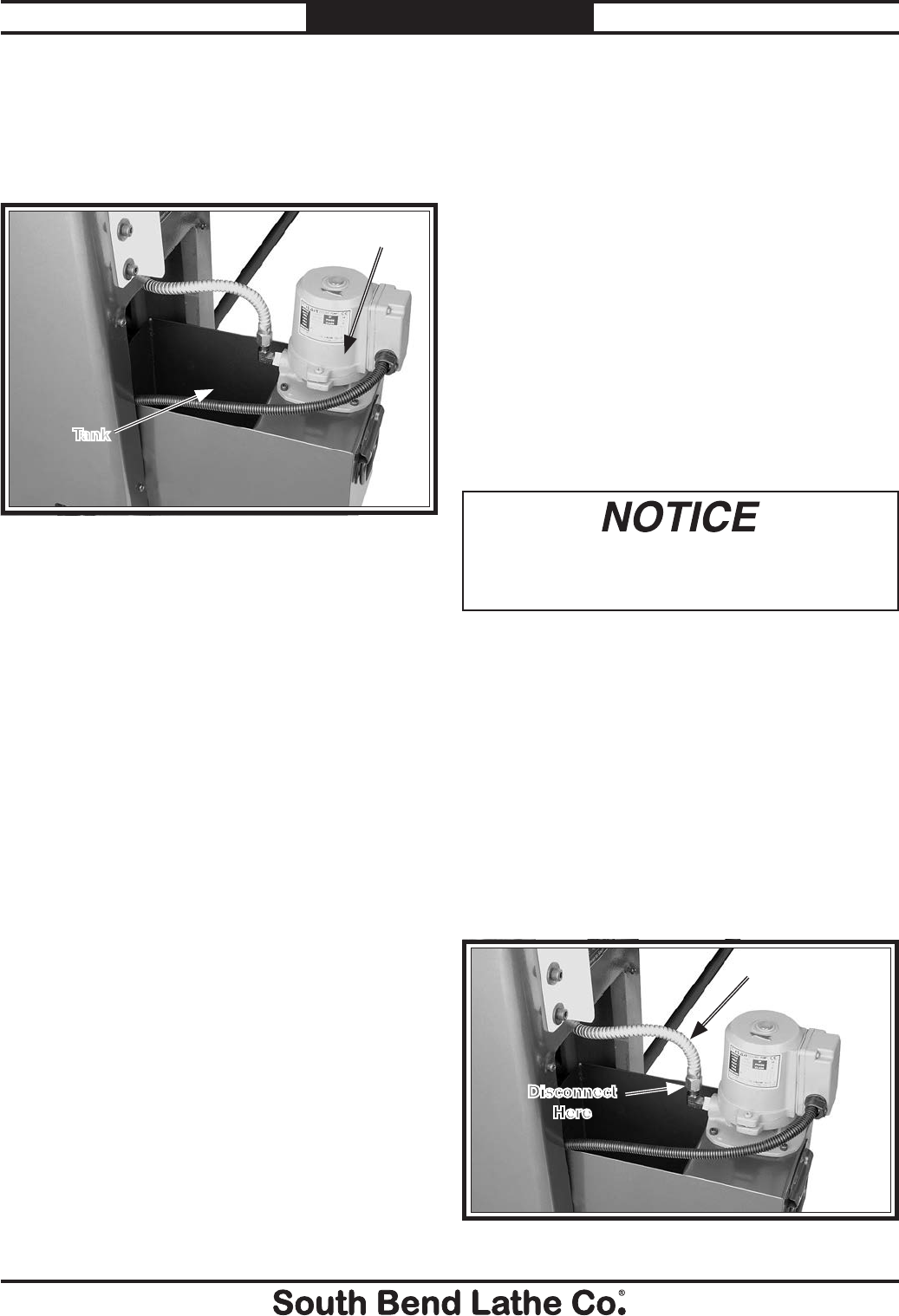

1. DISCONNECT LATHE FROM POWER!

2. Remove the vented cover and slide the tank

out, as shown in Figure 119.

Figure 119. Coolant tank and pump.

Pump

Running the coolant pump without adequate

fluid in the tank may permanently damage it,

which will not be covered under warranty.

3. Pour coolant into the tank until it is nearly

full.

4. Slide the tank back into the cabinet and

replace the vented cover.

Changing Coolant

When you replace the old coolant, take the time

to thoroughly clean out the chip drawer, catch

tray, and fluid tank. The entire job only takes

about a

1

⁄2 hour when you are prepared with the

proper materials and tools. Make sure to dispose

of old fluid according to federal, state, and fluid

manufacturer's requirements.

Items Needed: Qty

Safety Wear ......See Hazards section on Page 72

New Coolant ............................................ 3 Gallons

Empty 5-Gallon Bucket w/Lid .............................. 2

Phillips Screwdriver #2 ........................................1

Wrench

3

⁄4" .............................................................1

Disposable Shop Rags ........................... As Needed

Hose or Tubing

5

⁄8" x 60" (Optional) ........... 1 Piece

Magnets (Optional) ...............As Many As Desired

Tank

4. DISCONNECT LATHE FROM POWER!

5. Remove the vented cover and slide the tank

out.

6. To enable the remaining fluid to be poured

out in the next step, disconnect the fluid hose

from the pump (see Figure 120).

Note: The electrical conduit was purposely

left long, so the tank can be removed and

dumped out without disconnecting wires

from the pump.

Figure 120. Fluid hose and connection.

Fluid Hose

Disconnect

Here