For Machines Mfg. Since 3/11 16-Speed Gearhead Lathe

-75-

MAINTENANCE

To prepare your machine for long-term storage (a

year or more):

1. Run the lathe and bring all gearboxes to

operating temperature, then drain and refill

them with clean oil.

2. Pump out the old coolant, and remove and

blow out lines with compressed air and a few

drops of way oil.

3. DISCONNECT LATHE FROM POWER!

4. Thoroughly clean all unpainted, bare metal

surfaces, then apply a liberal coat of way

oil, heavy grease, or rust preventative. Take

care to ensure these surfaces are completely

covered but that the rust preventative or

grease is kept off of painted surfaces.

5. Lubricate the machine as outlined in the

lubrication section. Be sure to use the oil gun

to purge all ball oilers and oil passages with

fresh oil.

6. Loosen or remove machine belts so they do

not become stretched during the storage

period. (Be sure to place a maintenance note

near the power button as a reminder that

the belts have been loosened or removed.)

7. Place a few moisture absorbing desiccant

packs inside of the electrical box.

8. Cover the lathe and place it in a dry area

that is out of direct sunlight and away from

hazardous fumes, paint, solvents, or gas.

Fumes and sunlight can bleach or discolor

paint and make the chuck guard cloudy.

9. Every few months, by hand rotate all gear-

driven components a few times in several

gear selections. This will keep the bearings,

bushings, gears, and shafts well lubricated

and protected from corrosion—especially

during the winter months.

Slide the carriage, micrometer stop,

tailstock, and steady rest down the lathe

bed to make sure that way spotting is not

beginning to occur.

Backlash Adjustment

Backlash is the amount of free play felt while

changing rotation directions with the handwheel.

This can be adjusted on the compound rest

and cross slide leadscrews. Before beginning

any adjustment, make sure that all associated

components have been cleaned and lubricated.

Compound Rest

Tools Needed: Qty

Hex Wrench 3mm .................................................1

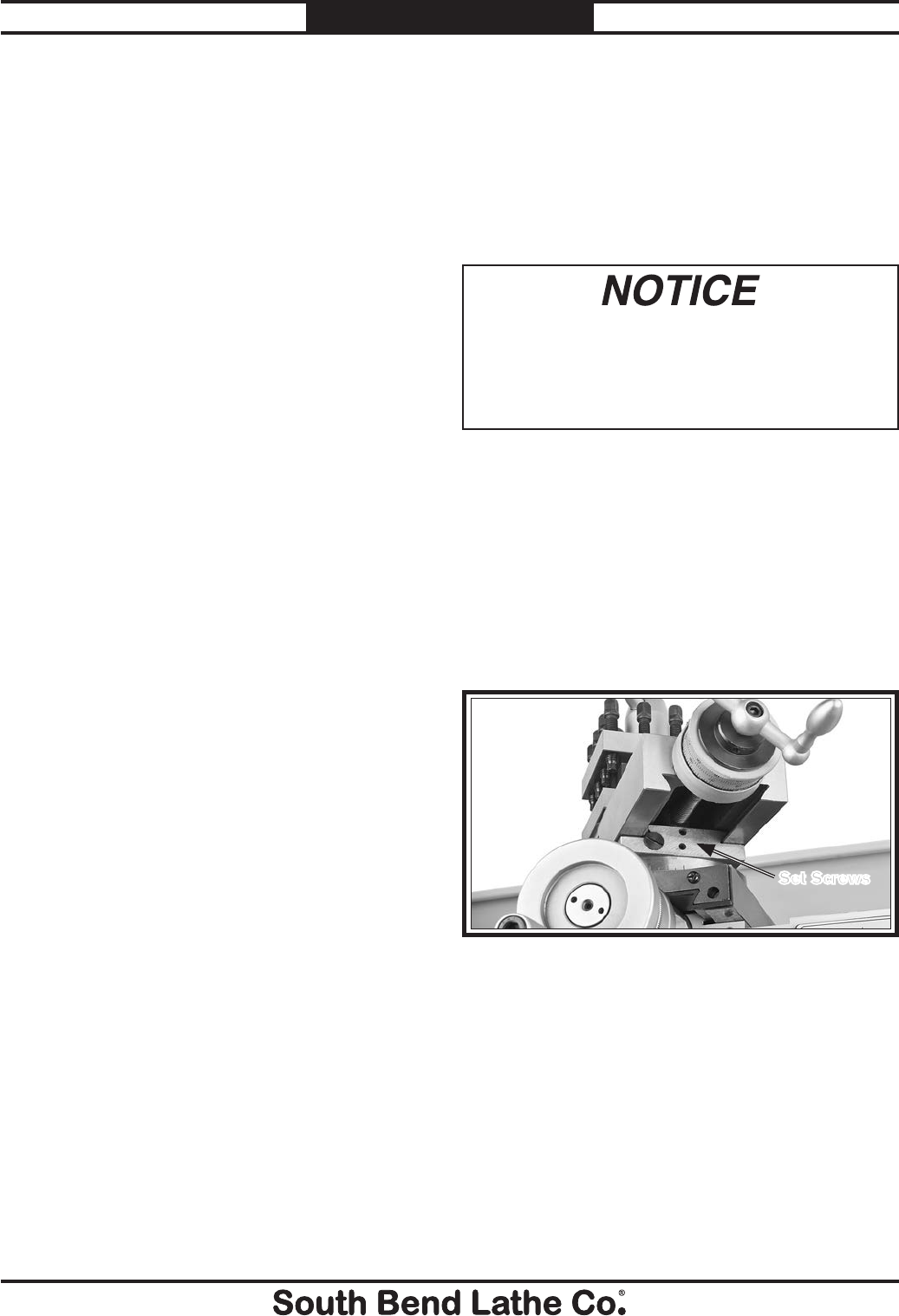

The compound rest backlash is adjusted by

tightening the set screws shown in Figure

121. When these screws are adjusted against

the leadscrew nut, they offset part of the nut to

remove play between the nut and leadscrew.

Figure 121. Compound rest backlash adjustment set

screws.

Set Screws

Reducing backlash to less than 0.002" is

impractical and can lead to accelerated wear

of the wedge, nut, and leadscrew. Avoid the

temptation to overtighten the backlash set

screw while adjusting.

To adjust the backlash, rock the handwheel back-

and-forth, and tighten the screws slowly until

the backlash is approximately 0.002"–0.003", as

indicated on the handwheel dial.

If you end up adjusting the nut too tight, loosen

the set screws, tap the compound rest a few

times with a rubber or wooden mallet, and turn

the handwheel slowly back-and-forth until it

moves freely, then try again.