For Machines Mfg. Since 3/11 16-Speed Gearhead Lathe

-85-

SERVICE

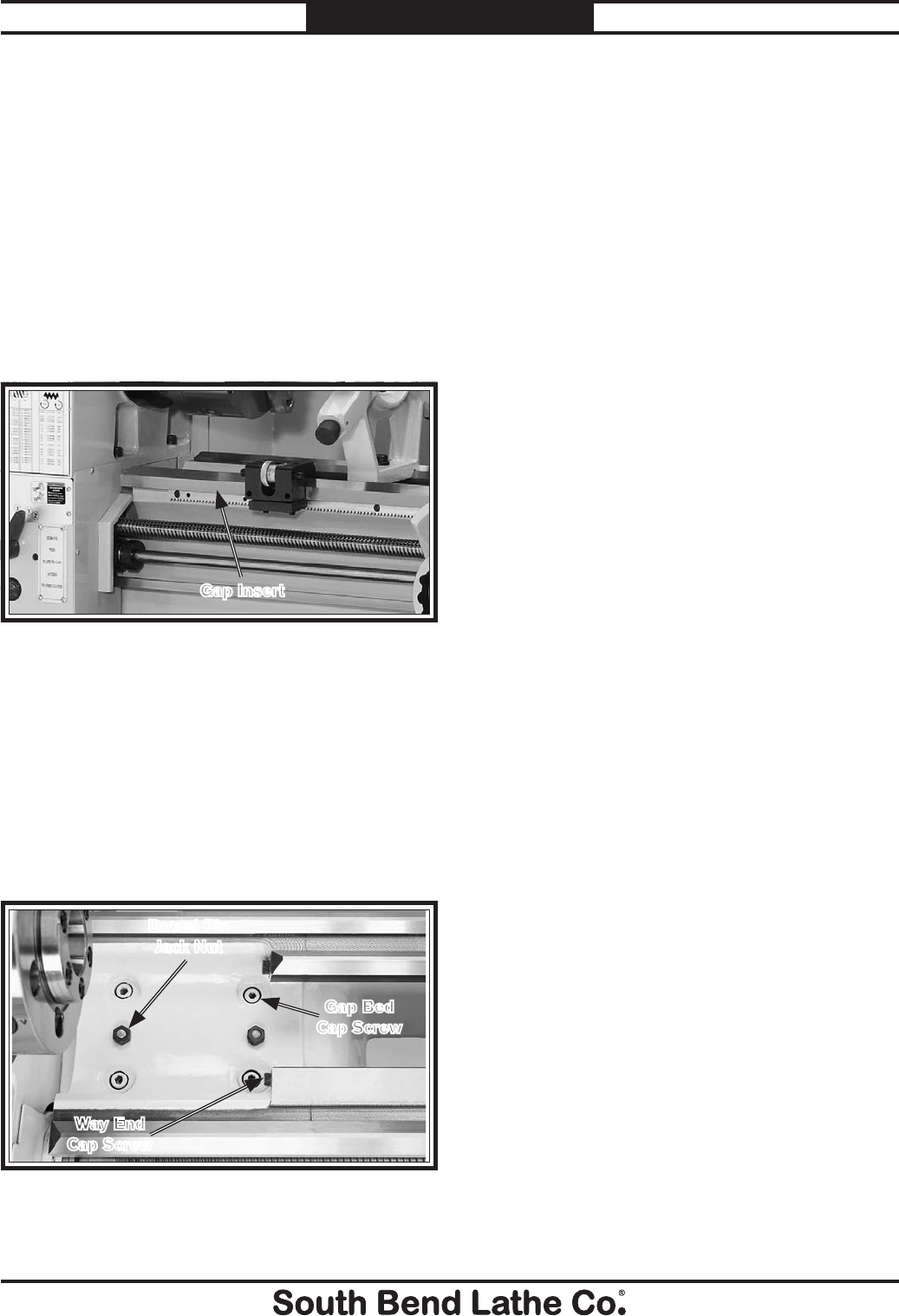

The gap insert directly under the spindle (see

Figure 146) can be removed to create additional

space for turning large diameter parts.

The gap insert was installed, then ground flush

with the bed at the factory to ensure a precision

fit and alignment. Therefore, if the gap insert is

removed, it may be difficult to re-install with the

same degree of accuracy.

Gap Insert Removal &

Installation

Tools Needed: Qty

Hex Wrenches 6mm ..............................................1

Hex Wrench 8mm .................................................1

Wrench 17mm .......................................................1

Dead Blow Hammer ..............................................1

Gap Removal

1. Remove the four gap-bed cap screws, shown

in Figure 147.

Figure 146. Gap insert.

Gap Insert

Figure 147. Fasteners holding gap in place.

Gap Bed

Cap Screw

Way End

Cap Screw

Dowel Pin

Jack Nut

2. Remove the two way-end cap screws.

3. Tighten the two dowel-pin jack nuts until the

pins are pulled free from the gap insert.

4. Tap the outside of the gap insert with a dead

blow hammer to loosen it, then remove it.

Gap Installation

1. Use mineral spirits and a clean lint-free rag

to clean the mating surfaces of the gap, bed,

and ways. If necessary, stone the mating

surfaces to remove scratches, dings, or burrs.

2. Wipe a thin layer of light machine oil on the

mating surfaces.

3. Place the gap insert into the gap and use a

dead-blow hammer to align the insert with

the lathe bed.

4. Back off the dowel pin jack nuts, and lightly

tap the dowel pins back into their respective

holes until they are seated. This process will

further help align the gap insert and bed

mating surfaces.

5. Install all fasteners and lightly snug them in

place.

6. Mount a dial indicator with a magnetic base

to the top of the saddle to indicate alignment.

7. First test the peak of the two prisms of the

gap insert that the saddle rides on, then test

the flanks of the prisms.

8. Tighten the gap bed cap screws in an

alternating manner and tap the side of the

gap insert into alignment.

9. Inspect the gap alignment 24 hours later

to make sure the gap is still aligned. If

necessary, loosen the gap bed cap screws and

repeat Steps 7–8 until the insert is properly

aligned.