Super Finish 27 • 31

32

GB

Starting operation/ Spraying technique

Attention

Completely unroll a connected cabledrum.

Attention

So that in switching on the unit the mains

fuse protection of 16 A does not react: Always

switch on the Super Finish 27 or31 unit rst

and then the connected unit.

5.

Guide the spray gun evenly during the spraying process. If

this is not observe, an irregular spraying appearance will be

the result. Spray with the arm and not with the wrist. Maintain

a parallel distance of approx. 30 cm, between the spray gun

and object of spraying. The lateral limitation of the spray jet

should not to be too distinct. The edge of the spraying should

be gradual to facilitate overlapping of the next coat. Always

guide the spray gun parallel to and at an angle of 90°to the

spraying area; in this way the least paint cloud arises.

i

If very distinct edge zones appear and streaks

in the spray jet – increase operating pressure or

dilute coating material.

Avoid bending or folding the high-pressure hose sharply;

smallest bending radius approx. 10 cm.

Do not run over the high-pressure hose and protect it from

sharp objects and edges.

Attention

There is danger of injury as a result of a leak-

ing high-pressure hose. Replace high-pressure

hose immediately.

Never repair the high-pressure hose your-self!

The unit is equipped with high-pressure hose specially suited

for diaphragm pumps.

i

For reasons of function, safety and durability,

only use original WAGNER high-pressure hoses.

7.

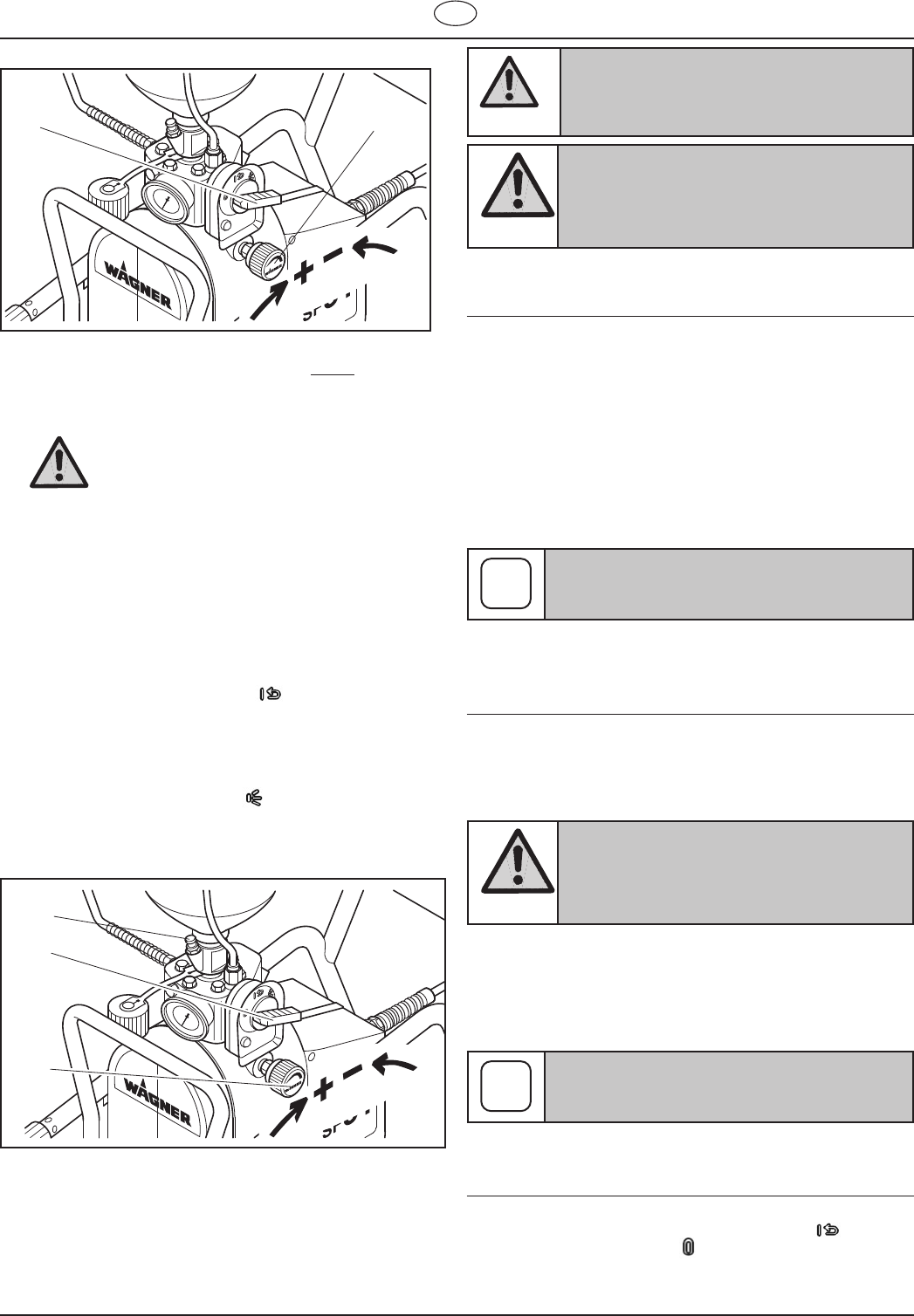

Switch o unit, set multifunction switch to

1.

(pressure

relief, circulation), then to (OFF).

Secure spray gun, see operating manual for spray gun.2.

If the tip is to be cleaned, see page 45, point 13.2.3.

3

5

4

1

2

4.7

1.

Super Finish 27

Attention

Before mounting suction system or upper hopper,

check inlet valve for functionality. Press inlet valve

with a soft implement (e.g. a pencil); it must allow

movement.

2.

Submerge suction pipe into a container lled with coating

material.

3.

Fill coating material into the upper hopper.

4.

Press inlet valve trigger (g 11, item 1) several times to

release possibly clogged inlet valve.

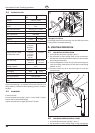

Set multifunction switch (2) to

5.

(ON - circulation); the

unit will start. Turn pressure regulating knob (3) to the right

until stop.

When the sound of the valves can be heard clearly, the unit 6.

is ventilated.

Set multifunction switch (2) to

7.

(spray). Pull trigger guard

of spray gun, then set the desired operating pressure by

means of the pressure regulating knob (3).

The unit is ready for spraying.8.

3

5

4

1

2

3

4.8

It is possible, for example, to connect an agitator, a working

lamp etc with a .

Interruption of work