Super Finish 27 • 31

27

GB

Safety regulations / General view of application

Adequate ventilation must be guaranteed for the removal

of the solvent vapours.

Suction installations

These are to be set-up by the user of the unit according to lo-

cal regulations.

The object to be coated must be earthed.

Danger

When cleaning the unit with solvents, the solvent

should never be sprayed or pumped back into a

container with a small opening (bunghole). An ex-

plosive gas/air mixture can be produced. The con-

tainer must be earthed.

Danger

Danger of short circuit through penetrating

or high-pressure steam cleaners.

Socket on unit

Only carry out damp cleaning in the area of the socket

and the multifunction switch when the mains plug is re-

moved.

Only have this work carried out by a qualied electrician.

No liability will be taken for incorrect installation.

works.

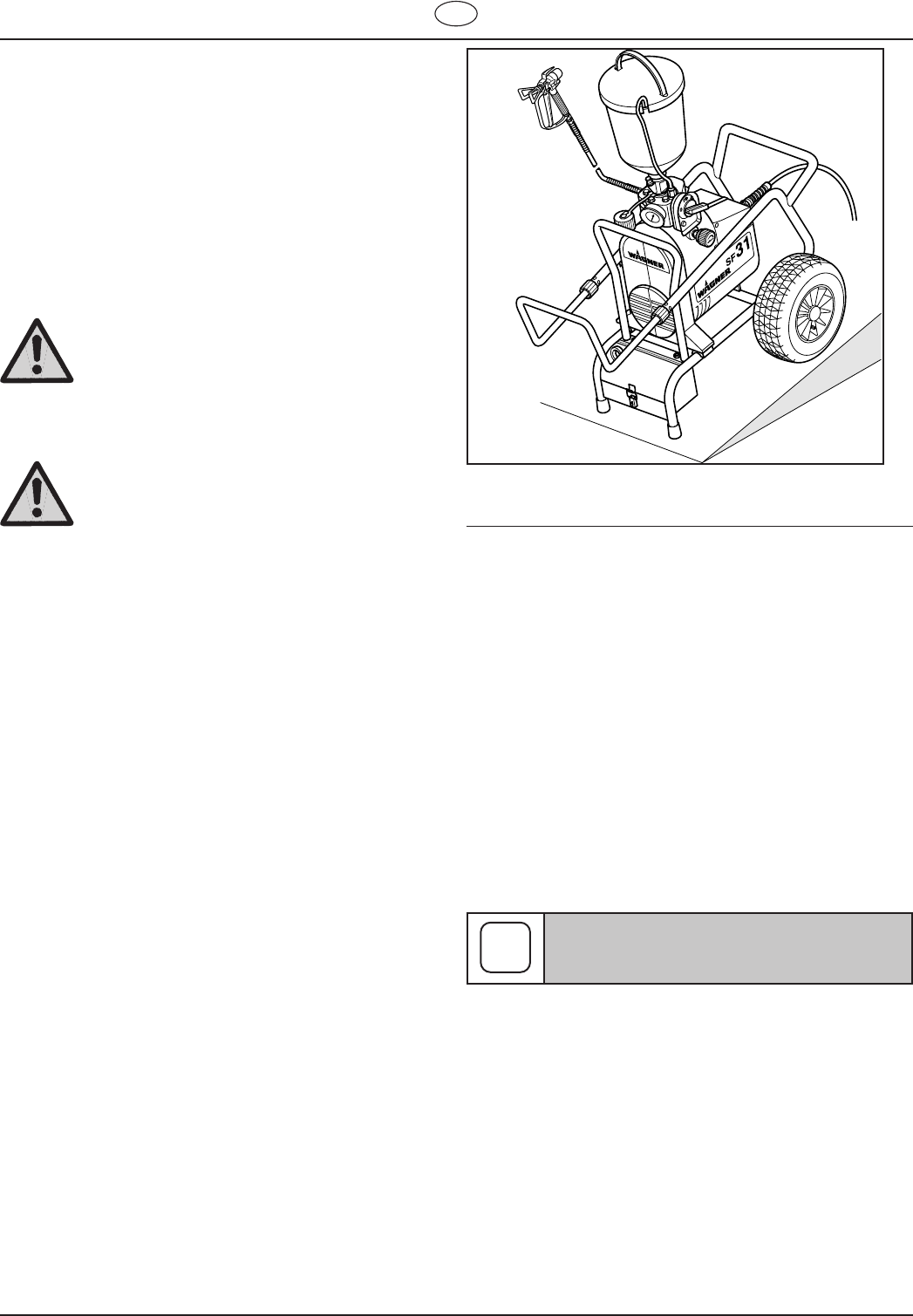

Setting-up on uneven surfaces

The front side of the unit must point downwards to prevent

sliding away. (g. 1)

3

5

4

2.

All painting jobs in the workshop and on the building site,

small and large-area dispersion work with the spray gun or in-

ternally fed Airless roller, corrosion and re protection.

Doors, door frames, balustrades, furniture, wooden cladding,

fences, radiators (heating) and steel parts, internal ceilings and

walls, and also façades, basement garages, re and noise pro-

tection for steel and wooden construction.

2.2

i

Pay attention to the Airless quality of the

coating materials to be processed.

Dilutable lacquers and paints or those containing solvents,

two-component coating materials, dispersions, latex paints,

façade paints, roof and attic coatings, re and corrosion pro-

tection material.

No other materials should be used for spraying without WAG-

NER’s approval.

Filtering

In spite of the suction lter, the insertion lter in the spray gun

and the high-pressure lter obtainable as accessory, ltering

of the coating material is to be recommended in general.

Stir coating material before commencement of work.