Super Finish 27 • 31

34

GB

Cleaning unit from outside

(4) and O-ring (5).

Roll in lter insert (3) (for lter insert with 70 mesh this is not

3.

necessary) and pull out of supporting part (2).

Clean all parts with appropriate cleaning agent. If pressure 4.

air is existent – blow through lter insert and supporting

part.

Remount high-pressure lter.5.

1

5

3

2

4

8.4

Rinse Airless spray gun with an appropriate cleaning agent.

•

Clean tip thoroughly with appropriate cleaning agent so that

•

no coating material residue re-mains.

Thoroughly clean the outside of the Airless spray gun.

•

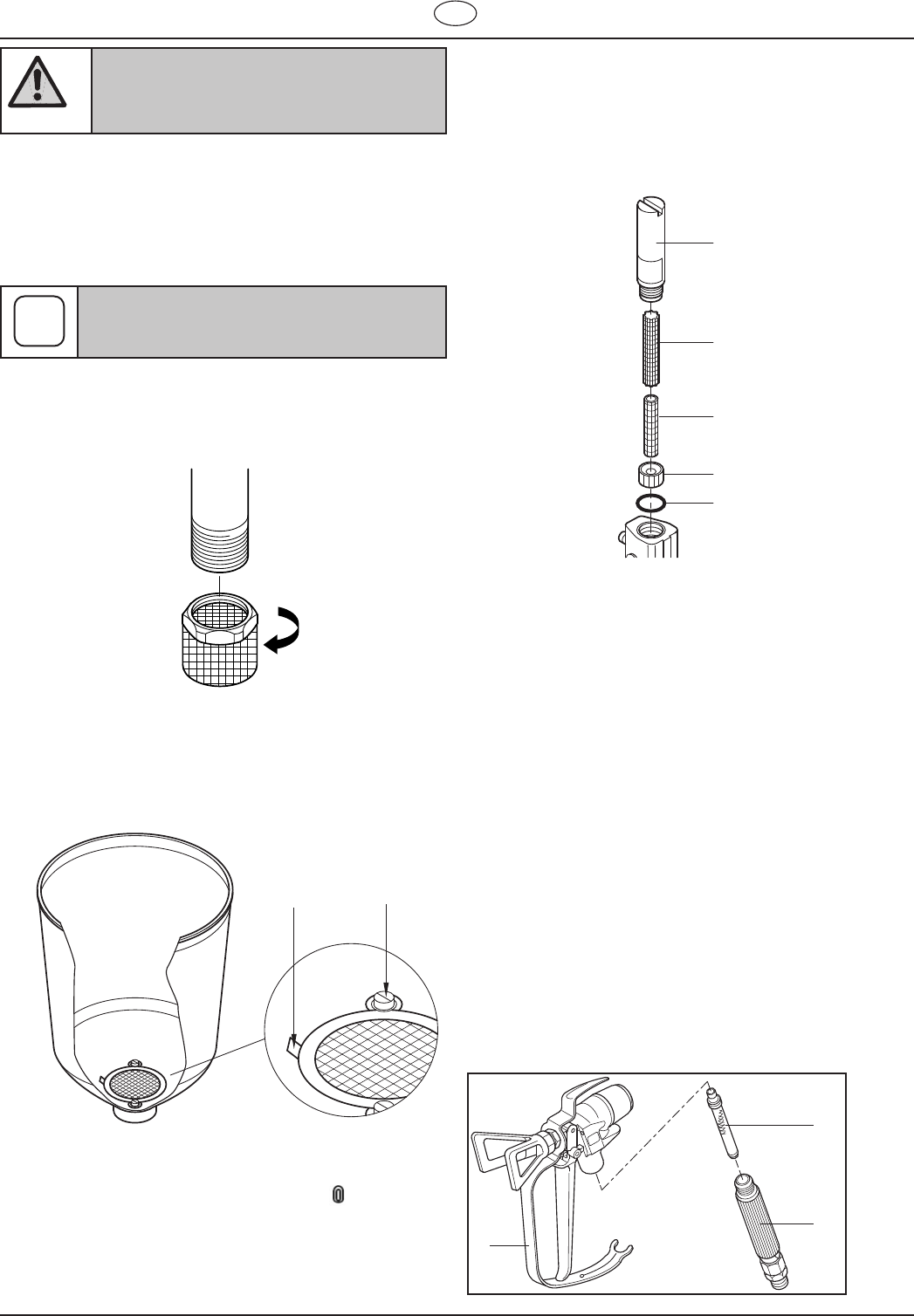

Pull protective guard (1) forward vigorously.1.

Screw grip (2) out of the gun housing. Remove intake lter 2.

(3).

Intake lter congested or defective – replace.3.

Mounting

Place intake lter (3) with the long cone into the gun

1.

housing.

Screw in grip (2) into the gun housing and tighten.2.

Slot in protective guard (1).3.

Made in Germany

max.

3900 psi

270 bar

G12

1

2

3

Danger

Danger of short circuit through penetrating

pressure or high-pressure steam cleaners.

Wipe down unit externally with a cloth which has been im-

mersed in a suitable cleaning agent.

Clean socket and the multifunction switch areas meticulously

also.

8.2

i

Clean lters also guarantee the maximum con-

veyance quantity, constant spraying pressure

and faultless function of the unit.

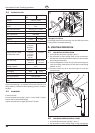

Screw o the lter (g. 13) from suction pipe.1.

Clean or replace the lter. Carry out cleaning with a hard 2.

brush and an appropriate cleaning agent.

Release screws with a screwdriver (g. 14,item 1).1.

Lift (2) and remove lter disk with a screwdriver.2.

Clean or replace the lter disk. Carry out cleaning with a

3.

hard brush and an appropriate cleaning agent.

2

1

Switch o unit – set multifunction switch to

•

(OFF).

Open high-pressure lter and clean lter insert; in addition:

•

Insert open-ended spanner into the groove of the lter

1.

housing (g. 15, item 1) – screw out lter housing.

Remove lter housing (1), supporting part (2), centring ring 2.