Super Finish 27 • 31

36

GB

Remedy in case of disturbance/ Servicing

Measure for elimination of mal-

function

Inlet valve does not close as, for

•

example, the guidance is clogged

Outlet valve is clogged

•

Screw inlet valve out of the paint section

•

and clean, see page 37, point 11.2

Screw the outlet valve out of the paint

•

section and clean, see page 37, point 11.3

up of pressure takes place

Air in the hydraulic system

•

Release air from unit (hydraulic system),

•

i.e. turn pressure regulating valve three

revolutions to the left. Allow the unit to

run one or two minutes. After that, turn

pressure regulating valve to the right to

set the desired operating pressure.

pressure. If the spray gun is re-

-

ciably

No tip in the spray gun

•

Tip too large

•

Suction lter clogged

•

Specially for unit with suction sys-

tem:

Suction pipe not tight

•

Outlet valve parts worn

•

Relief valve does not close. Coating

•

material escapes at switch position

(spray) from the return pipe.

Mount tip.

•

Selection of smaller tip, see page 46, point

•

13.4.

Clean suction lter or replace.

•

Clean and tighten connection points.

•

Replace outlet valve parts, see page 37,

•

point 11.3.

Screw out relief valve from paint section and

•

clean or replace, see page 38, point11.5.

vibration on the spray gun and

unit

High-pressure hose for diaphragm

•

unit not suitable

Outlet valve parts worn

•

Use original WAGNER high-pressure hose.

•

Replace outlet valve parts, see page 37,

•

point 11.3.

Servicing of the unit should be carried out once annually by

the WAGNER service.

Check high-pressure hoses, unit connection line, plug and 1.

socket for damage.

Check inlet valve, outlet valve, diaphragm and lter for

2.

wear.

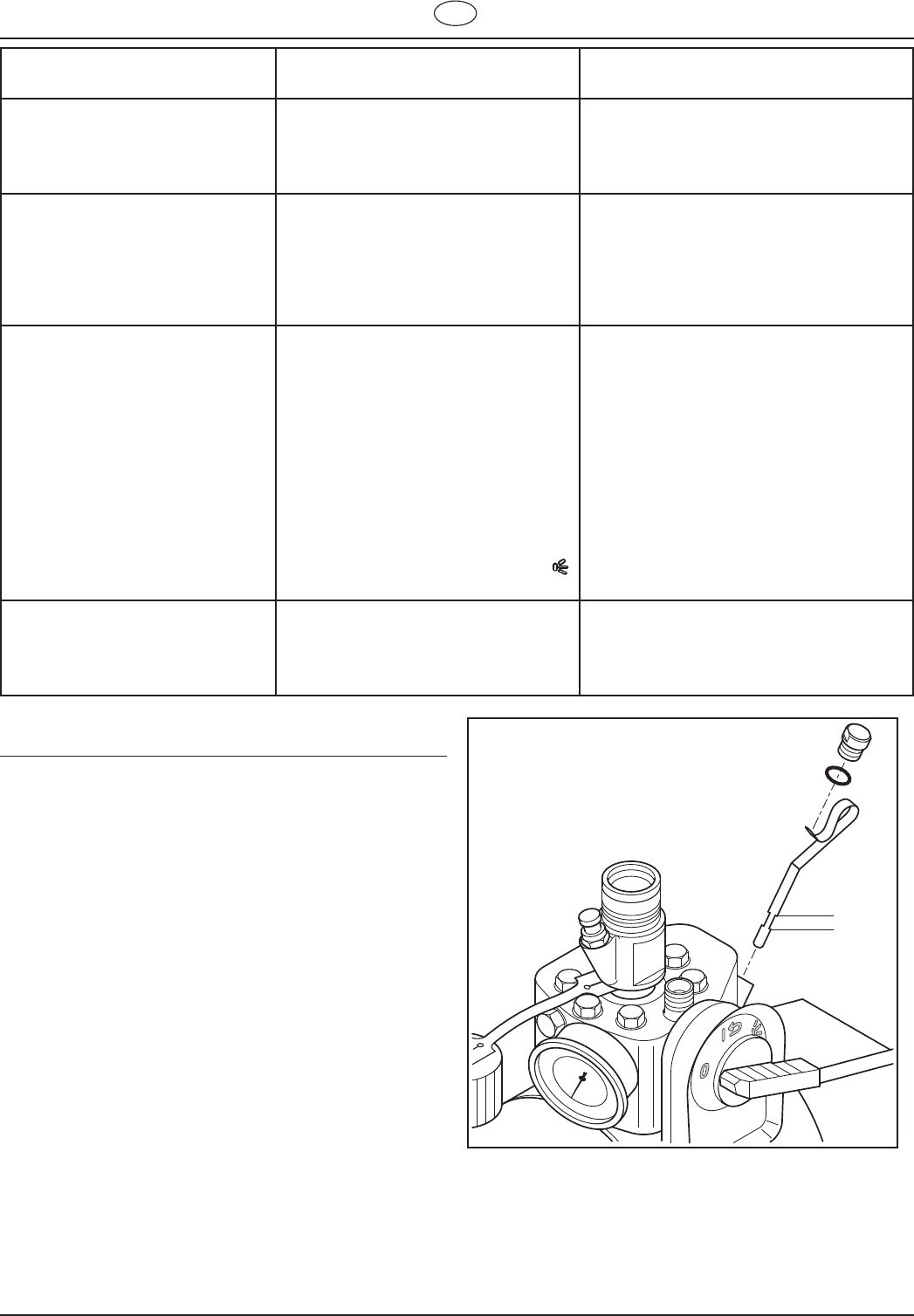

Check oil level (g. 18) in the horizontal set-up.3.

max.

min.

Check high-pressure hose optically for any cuts or bulges in

particular at the connection to the tting. Union nuts must be

able to be turned freely.