-3-

$&! !

Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only.

($(&!!$' ' &&

Turn power off. Don’t leave tool until it comes to a

complete stop.

&;;8->1

! !&&$!$%'%&!!

These tools are precision built. Any alteration or

modification not specified is misuse and may result

in dangerous con ditions.

(!%!'%$%

Do not operate electric tools in gaseous or explosive

at mo spheres. Motors in these tools normally spark,

and may re sult in a dangerous condition.

& &!!%)&$

Keep tools sharp and clean for better and safer

perfor mance. Follow instructions for lubricating and

changing ac cessories. Inspect tool cords periodi-

cally and if damaged, have repaired by authorized

service facility. Inspect ex tension cords periodically

and replace if damaged. Keep handles dry, clean

and free from oil and grease.

Before connecting the tool to a

power source (receptacle, outlet,

etc.), be sure voltage supplied is the same as that

specified on the nameplate of the tool. A power

source with voltage greater than that specified for

the tool can result in serious injury to the user — as

well as damage to the tool. If in doubt, DO NOT

PLUG IN THE TOOL. Using a power source with

voltage less than the nameplate rating is harmful to

the motor.

For your own safety, do not operate

your table saw until it is completely

assembled and installed according to the instruc-

tions … and until you have read and understood the

following:

1. General Safety Rules. . . . . . . . . . . . . . . . . . 2–5

2. Double Insulated Tools . . . . . . . . . . . . . . . . . . . 6

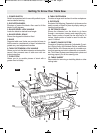

3. Getting To Know Your Table Saw. . . . . . . . 9, 10

4. Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 12–16

5. Adjustments . . . . . . . . . . . . . . . . . . . . . . . 17–21

6. Basic Table Saw Operation . . . . . . . . . . . 22–34

7. Maintaining Your Table Saw. . . . . . . . . . . 34–35

%&&+!%)

Your table saw MUST BE BOLTED securely to a

stand or workbench. In addition, if there is any ten-

dency for the table saw to tip over or move during

certain operations such as cutting long, heavy

boards, use an auxiliary support.

!&!

Use the table saw in a well lit area and on a level

surface, clean and smooth enough to reduce the risk

of trips and falls. Use it where neither the operator

nor the casual observer is forced to stand in line with

the blade.

Kickbacks can cause serious injury: A “KICKBACK”

occurs when a part of the workpiece binds between

the sawblade and the rip fence or other fixed object.

Workpiece binding the blade due to misalignment,

can also cause kickback. During kickback, work-

piece rises from table and is thrown toward the op-

erator. Keep your face and body to one side of the

sawblade, out of line with a possible “KICKBACK”.

% "!%% '$+

'%'+(!+

- Maintaining the rip fence parallel to the sawblade.

.Keeping the sawblade sharp. Replacing or sharp-

ening anti-kickback pawls when points become dull.

/Keeping sawblade guard, spreader and anti-kick-

back pawls in place and operating properly. The

spreader must be in alignment with the sawblade

and the pawls must stop a kickback once it has

started. Check their action before ripping.

0NOT ripping workpiece that is twisted or warped

or does not have a straight edge to guide along the

rip fence.

1NOT releasing work until you have pushed it all

the way past the sawblade.

2Using a Push Stick for ripping widths of 2" to 6"

and an auxiliary fence and Push Block for ripping

widths narrower than 2" (See “Basic Saw Operation,

Using The Rip Fence” section, pages 29, 30).

3NOT confining the cut-off piece when ripping or

cross cutting.

4When ripping, apply the feed force to the section

of the workpiece between the sawblade and the rip

fence. Use Push Stick or Push Block when appro-

priate (See item f. above).

H%(&% %&$'&! %I

005@5;:-8%-21@E$A81?

!

WARNING

!

WARNING

BM 2610014415 01-11 E:BM 2610012089 12-10 E 1/10/11 7:17 AM Page 3