Basic Saw Operations (continued) ...................

Ploughing and Molding

Ploughing fs grooving with the grain the tong way of the

workpiece, using the fence Use featherboards and push

sticks as required

Molding is shaping the workpiece with the grain the long

way of the workpiece, using the fence. Use feather-

boards and push sticks as required

Ploughing

Molding Cutting

Instructions for operating the molding head are contained

in a booklet furnished with the molding head..

Always use the molding insert listed under recom-

mended accessories.

When using the molding head it will be necessary to

remove the blade guard and spreader Use caution Use

miter gauge, fence, featherboards, or push sticks, etc.,

as required

I WARNING: For your own safety, always replace the I

blade guard and spreader when you finished plough-

Iing or molding.

Molding

Adjustments

WARNING: For your own safety, turn switch "OFF"

and remove plug from power source outlet before

making any adjustments,

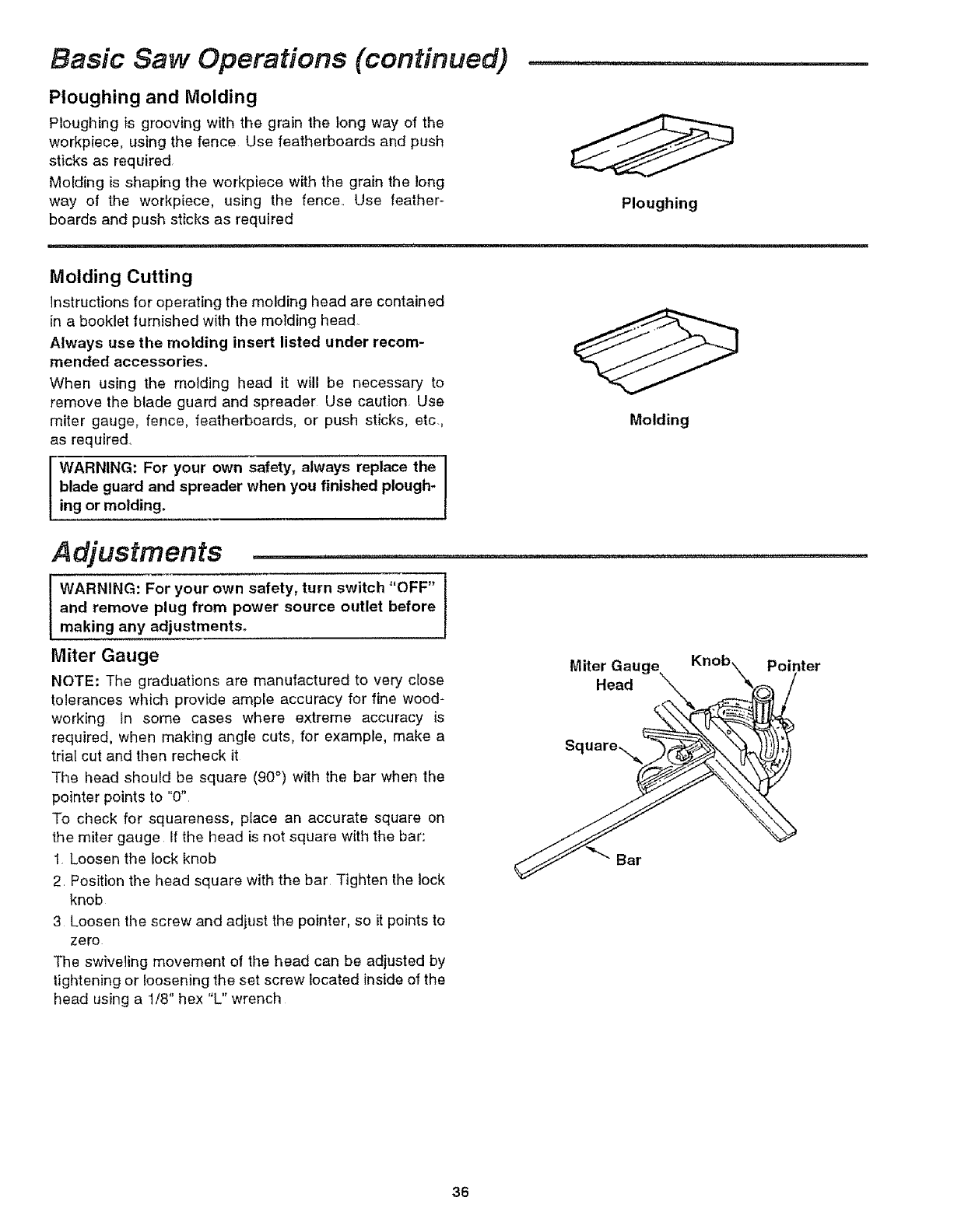

Miter Gauge

NOTE: The graduations are manutactured to very close

tolerances which provide ample accuracy for fine wood-

working In some cases where extreme accuracy is

required, when making angle cuts, for example, make a

trial cut and then recheck it

The head should be square (90°) with the bar when the

pointer points to "0"

To check for squareness, place an accurate square on

the miter gauge itthe head is not square with the bar:

1 Loosen the lock knob

2. Position the head square with the bar Tighten the lock

knob

3 Loosen the screw and adjust the pointer, so it points to

zero

The swiveling movement of the head can be adjusted by

tightening or loosening the set screw located inside of the

head using a 1/8" hex "L" wrench

1

Miter Gauc Knob Pointer

Head

Bar

36