Heeling Adjustment or Parallelism of Saw-

blade to Miter Gauge Groove

While cutting, the materia_ must move in a straight line

parallel to the sawblade Therefore, both the miter gauge

groove and the rip fence must be parallel to the saw-

blade

I WARNING: The blade be to the miter

must

parallel

gauge groove. Misatigned blades could bind on

workpiece. Workpiece could suddenly kickback.

You could be cut or hit.

If the sawblade is not parallel to the miter gauge groove,

the blade will bind at one end of the cut This is known as

"Heeling")

WARNING: To avoid injury from accidental start,

make sure switch is "OFF" and plug is not con-

nected to power source outlet.

To check for parallelism:

1,,Raise blade all the way up, raise blade guard

2 Mark an "X" on one of the teeth of the sawblade which

is naturally bent to the left

3 Place the head of a combination square in the left

miter gauge groove Adjust ruler blade of square so

that it just touches the tip of the marked tooth Remem-

ber to keep the head of the square flush against the

miter gauge groove

4 Rotate the sawblade so that the "X" on the tooth is now

visible at the rear of the saw

5 Move combination square to the rear of the SaWr The

end of the square blade should just touch the marked

tooth the same as it did at the front of the sawblade

6 If sawblade is not parallel with the miter gauge groove,

you must adjust the position of the sawblade

To Adjust For Blade Heel:

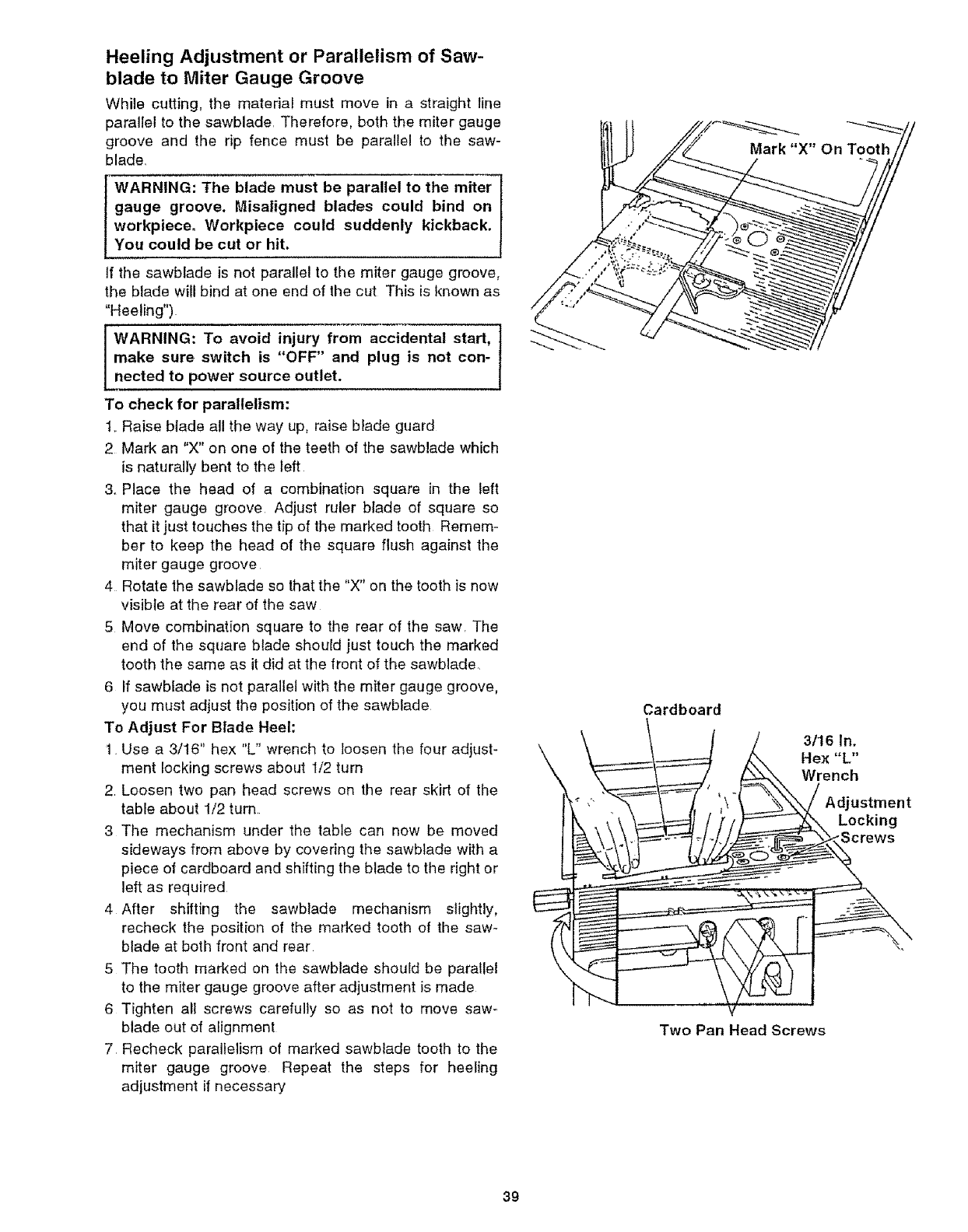

1 Use a 3/16" hex "L" wrench to loosen the four adjust-

ment locking screws about 1/2 turn

2 Loosen two pan head screws on the rear skirt of the

table about 1/2 turn,

3 The mechanism under the table can now be moved

sideways from above by covering the sawblade with a

piece of cardboard and shifting the blade to the right or

left as required

4After shifting the sawblade mechanism slightly,

recheck the position of the marked tooth of the saw-

blade at both front and rear

5 The tooth marked on the sawblade should be parallel

to the miter gauge groove after adjustment ismade

6 Tighten all screws carefully so as not to move saw-

blade out of alignment

7 Recheck parallelism of marked sawblade tooth to the

miter gauge groove Repeat the steps for heeling

adjustment if necessary

\

Cardboard

3t16 In.

Hex "L"

Wrench

Adjustment

Locking

Screws

v

Two Pan Head Screws

39