Motor Specifications and Electrical Requirements (continued)

CAUTION: To avoid motor damage, this motor

should be blown out or vacuumed frequently to

prevent sawdust buildup which will interfere with

normal motor ventilation,

1 Frequent "blowing" of fuses or tripping of circuit break-

ers may result if:

a Motor is overloaded - Overloading can occur if you

feed too rapidly or if saw is misaligned

b, Motor circuit is fused differently from recommenda-

tions - Always follow instructionsfor the proper fuse/

breaker Do not use a fuse/breaker of greater

capacity without consulting a qualified electrician

c Low voltage - Although the motor is designed for

operation on the voltage and frequency specified on

motor nameplate, normal loads will be handled

safely on voltage not more than 10% above or below

the nameplate voltage Heavy loads, however,

require that voltage at motor terminals equals the

voltage specified on nameplate,

2. Most motor troubles may be traced to loose or incor-

rect connections, overloading, reduced input voltage

(such as small size wire in the supply circuit) or to

overly long supply circuit wire, Always check the con-

nections, the load and the supply circuit whenever

motor fails to perform satisfactorily Check wire sizes

and length with the Wire Size Chart below

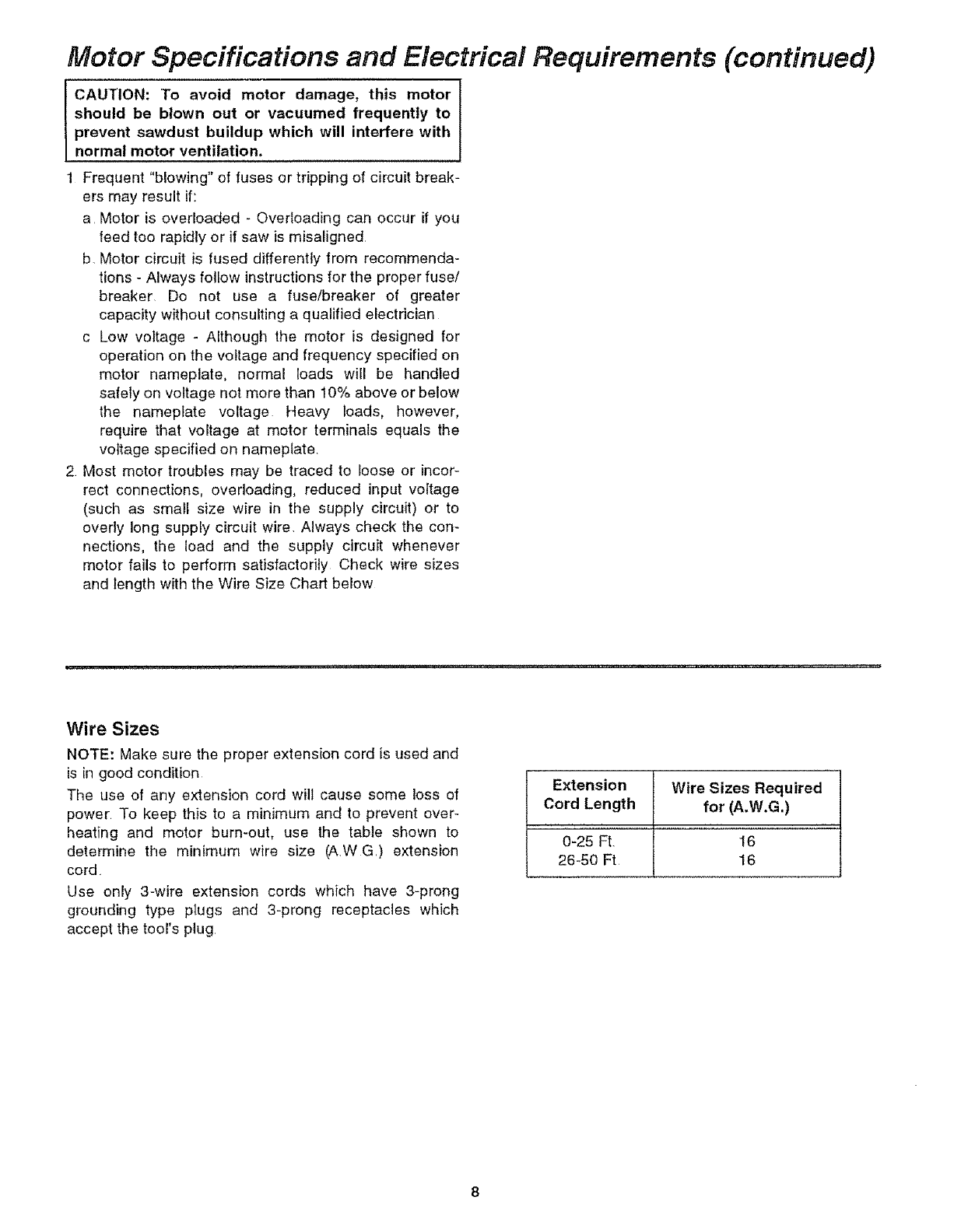

Wire Sizes

NOTE: Make sure the proper extension cord is used and

is in good condition

The use of any extension cord will cause some loss o!

power To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table shown to

determine the minimum wire size (AWG,) extension

cord

Use only 3-wire extension cords which have 3-prong

grounding type plugs and 3-prong receptacles which

accept the tool's plug

Extension

Cord Length

0-25 Ft,

26-50 Ft

Wire Sizes Required

for (A.W.G.)

16

16