28 Micro Motion 3098 Gas Specific Gravity Meter

Electrical Connections

3.6.4 Customer's equipment, 3-wire configuration

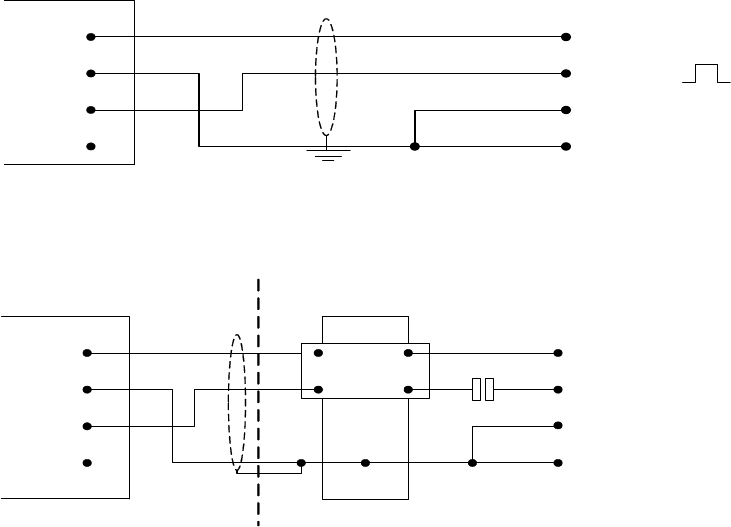

Figure 3-19 Electrical connections for meter 3-wire option used with customer’s own equipment (safe area)

Figure 3-20 Electrical connections for meter 3-wire option used with customers’ own equipment and

shunt-diode safety barrier (hazardous area)

3.7 Post-installation checks

After installation, the following procedure will indicate to a high degree of confidence that the meter

is operating correctly.

1. Electrical Check

Measure the current consumption and the supply voltage at the meter amplifier. This should be

within the following limits:

• 15.5 Vdc to 33 Vdc (Safe Areas)

• 15.5 Vdc to 24 Vdc (Hazardous Areas)

• 10 mA at 24 V dc input (Nominal input current)

• 17 mA maximum (Safe and Hazardous Areas, any input voltage)

2. Stability Check

Check the stability of the frequency output signal using a period meter on a 1000-cycle count.

The measurement scatter should be within ±2 ns. If this value is exceeded, it is likely that dirt

is present on the sensing element. This test may be performed at any gas density, provided that

the latter is not changing.

3098 meter

1

+

SIG A

2

-

3

+

SIG B

4

-

Power +

Power -

Signal +

Signal -

6V pk to pk

3098 meter

1

+

SIG A

2

-

3

+

SIG B

4

-

MTL 787 (+ve)

3

4

1

2

Hazardous Area Safe Area

Power + (24.25 to 27V DC, 30mA)

Power -

Signal +

Signal -

1nF